Incazelo Yomkhiqizo

Ulwazi Olujwayelekile - ASME/ANSI B16.5 & B16.47 - Ama-Flanges Amapayipi kanye Nezinto Zokufaka Ezihlanganisiwe

Izinga le-ASME B16.5 lihlanganisa izici ezahlukahlukene zama-flange amapayipi kanye nokufakwa kwe-flange, okuhlanganisa izilinganiso zokushisa kwengcindezi, izinto zokwakha, ubukhulu, ukubekezelelana, ukumaka, ukuhlola, kanye nokubeka izikhala zalezi zingxenye. Leli zinga lihlanganisa ama-flange anezimpawu zekilasi lokulinganisa ezisukela ku-150 kuya ku-2500, ezihlanganisa osayizi kusukela ku-NPS 1/2 kuya ku-NPS 24. Lihlinzeka ngezidingo kumayunithi e-metric kanye nase-US. Kubalulekile ukuqaphela ukuthi leli zinga likhawulelwe kuma-flange kanye nokufakwa kwe-flange okwenziwe ngezinto ezibunjiwe noma ezibunjiwe, okuhlanganisa ama-flange ayizimpumputhe kanye nama-flange athile okunciphisa enziwe ngezinto ezibunjiwe, ezibunjiwe, noma zepuleti.

Kuma-flange amapayipi kanye nokufakwa kwe-flange okungaphezu kuka-24" NPS, kufanele kubhekwe i-ASME/ANSI B16.47.

Izinhlobo Ezivamile Ze-Flange

● Ama-Flanges Ashelelayo: Lawa ma-flange avame ukufakwa ku-ANSI Class 150, 300, 600, 1500 kanye no-2500 kuze kufike ku-24" NPS. "Ashelela phezu" kwepayipi noma iziphetho zokufaka futhi ashiselwe endaweni yawo, okuvumela ukushisela kwe-fillet ngaphakathi nangaphandle kwe-flange. Izinguqulo zokunciphisa zisetshenziselwa ukunciphisa osayizi bomugqa lapho isikhala silinganiselwe.

● Ama-Flanges Entanyeni E-Weld: Lawa ma-flanges ane-hub ende ecacile ende kanye nokushintsha okubushelelezi kobukhulu, okuqinisekisa ukuthi i-weld ingena ngokugcwele epayipini noma ekufakweni. Asetshenziswa ezimweni ezinzima zesevisi.

● Ama-Lap Joint Flanges: Uma ehlanganiswe ne-stub end, ama-lap joint flanges afakwa phezu kwe-stub end fitting futhi axhunywe ngokushisela noma ngezinye izindlela. Ukwakheka kwawo okuxekethile kuvumela ukuhlangana okulula ngesikhathi sokuhlanganiswa nokuhlukaniswa.

● Ama-Backing Flanges: Lawa ma-flange awanakho ubuso obuphakanyisiwe futhi asetshenziswa nama-backing rings, ahlinzeka ngezixazululo ezingabizi kakhulu zokuxhuma ama-flange.

● Ama-Flanges Anemicu (Anezikulufo): Anemicu ehambisana nepayipi elithile ngaphakathi kobubanzi, ama-flanges anemicu afakwa ngomshini ngemicu yepayipi enciphile ohlangothini olungemuva, ikakhulukazi amapayipi amancane anemicu.

● Ama-Socket Weld Flanges: Afana nama-slip-on flanges, ama-socket weld flanges aklanywa ngomshini ukuze afane nama-sockets osayizi wepayipi, okuvumela ukushisela ama-fillet ohlangothini olungemuva ukuze kuqinisekiswe ukuxhumana. Ngokuvamile asetshenziselwa amapayipi amancane.

● Ama-Flanges Ayizimpumputhe: Lawa ma-flanges awanawo umgodi ophakathi futhi asetshenziselwa ukuvala noma ukuvimba ukuphela kohlelo lwamapayipi.

Lezi ezinye zezinhlobo ezivamile zama-flange amapayipi asetshenziswa ezinhlotsheni ezahlukene zezimboni nezentengiselwano. Ukukhetha uhlobo lwe-flange kuncike ezicini ezifana nokucindezela, izinga lokushisa, kanye nohlobo loketshezi oluthuthwayo, kanye nezidingo ezithile zephrojekthi. Ukukhetha nokufaka ama-flange ngendlela efanele kubalulekile ekusebenzeni okuphephile nokusebenza kahle kwezinhlelo zamapayipi.

Imininingwane

| I-ASME B16.5: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Yengxubevange |

| EN 1092-1: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

| I-DIN 2501: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

| I-GOST 33259: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Yengxubevange |

| I-SABS 1123: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

Izinto zeFlange

Ama-flange axhunyelwe kumapayipi kanye ne-nozzle yemishini. Ngakho-ke, akhiqizwa ngezinto ezilandelayo;

● Insimbi yekhabhoni

● Insimbi ephansi ye-alloy

● Insimbi engagqwali

● Inhlanganisela yezinto ezingavamile (i-Stub) nezinye izinto ezisekelayo

Uhlu lwezinto ezisetshenziswa ekukhiqizeni luhlanganiswe ku-ASME B16.5 kanye ne-B16.47.

● Ama-Flanges e-ASME B16.5 -Amapayipi kanye nokufakwa kwe-Flanged NPS ½” kuya ku-24”

● I-ASME B16.47 -Izibani Zensimbi Ezinkulu Ezinobubanzi Obukhulu I-NPS 26” kuya ku-60”

Izinto zokwakha ezisetshenziswa kakhulu

● Insimbi Yekhabhoni: – ASTM A105, ASTM A350 LF1/2, ASTM A181

● Insimbi Yengxubevange: – ASTM A182F1 /F2 /F5 /F7 /F9 /F11 /F12 /F22

● Insimbi Engagqwali: – ASTM A182F6 /F304 /F304L /F316 /F316L/ F321/F347/F348

Ubukhulu beFlange ye-Slip-on yekilasi le-150

| Usayizi ngamasentimitha | Usayizi ngo-mm | I-Dia yangaphandle. | I-Flange Eqinile. | I-Hub OD | Ubude beFlange | I-RF Dia. | Ukuphakama kwe-RF | I-PCD | Ibhore Lesokhethi | Inani lamaBolts | Usayizi we-Bolt UNC | Ubude beBolt yomshini | Ubude be-RF Stud | Usayizi Wembobo | Usayizi we-ISO Stud | Isisindo ngama-kg |

|

|

| A | B | C | D | E | F | G | H |

|

|

|

|

|

|

|

| 1/2 | 15 | 90 | 9.6 | 30 | 14 | 34.9 | 2 | 60.3 | 22.2 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.8 |

| 3/4 | 20 | 100 | 11.2 | 38 | 14 | 42.9 | 2 | 69.9 | 27.7 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 49 | 16 | 50.8 | 2 | 79.4 | 34.5 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 19 | 63.5 | 2 | 88.9 | 43.2 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 21 | 73 | 2 | 98.4 | 49.5 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.4 |

| 2 | 50 | 150 | 17.5 | 78 | 24 | 92.1 | 2 | 120.7 | 61.9 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 27 | 104.8 | 2 | 139.7 | 74.6 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 108 | 29 | 127 | 2 | 152.4 | 90.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.7 |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 30 | 139.7 | 2 | 177.8 | 103.4 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5 |

| 4 | 100 | 230 | 22.3 | 135 | 32 | 157.2 | 2 | 190.5 | 116.1 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 5 | 125 | 255 | 22.3 | 164 | 35 | 185.7 | 2 | 215.9 | 143.8 | 8 | 3/4 | 85 | 95 | 7/8 | I-M20 | 6.8 |

| 6 | 150 | 280 | 23.9 | 192 | 38 | 215.9 | 2 | 241.3 | 170.7 | 8 | 3/4 | 85 | 100 | 7/8 | I-M20 | 8.6 |

| 8 | 200 | 345 | 27 | 246 | 43 | 269.9 | 2 | 298.5 | 221.5 | 8 | 3/4 | 90 | 110 | 7/8 | I-M20 | 13.7 |

| 10 | 250 | 405 | 28.6 | 305 | 48 | 323.8 | 2 | 362 | 276.2 | 12 | 7/8 | 100 | 115 | 1 | M24 | 19.5 |

| 12 | 300 | 485 | 30.2 | 365 | 54 | 381 | 2 | 431.8 | 327 | 12 | 7/8 | 100 | 120 | 1 | M24 | 29 |

| 14 | 350 | 535 | 33.4 | 400 | 56 | 412.8 | 2 | 476.3 | 359.2 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 41 |

| 16 | 400 | 595 | 35 | 457 | 62 | 469.9 | 2 | 539.8 | 410.5 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 54 |

| 18 | 450 | 635 | 38.1 | 505 | 67 | 533.4 | 2 | 577.9 | 461.8 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | I-M30 | 59 |

| 20 | 500 | 700 | 41.3 | 559 | 71 | 584.2 | 2 | 635 | 513.1 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | I-M30 | 75 |

| 24 | 600 | 815 | 46.1 | 663 | 81 | 692.2 | 2 | 749.3 | 616 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 100 |

Ubukhulu beFlange yentamo ye-Weld yekilasi 150

| Usayizi ngamasentimitha | Usayizi ngo-mm | Ububanzi Bangaphandle | Ubukhulu be-Flange | I-Hub OD | Intamo Ehlanganisiwe OD | Ubude Bentamo Yokushisela | Ibhore | Ububanzi be-RF | Ukuphakama kwe-RF | I-PCD | Ubuso obuhlanganisiwe |

|

|

| A | B | C | D | E | F | G | H | I | J |

| 1/2 | 15 | 90 | 9.6 | 30 | 21.3 | 46 | Imbobo yentamo yokushisela itholakala ohlelweni lwepayipi | 34.9 | 2 | 60.3 | 1.6 |

| 3/4 | 20 | 100 | 11.2 | 38 | 26.7 | 51 | 42.9 | 2 | 69.9 | 1.6 | |

| 1 | 25 | 110 | 12.7 | 49 | 33.4 | 54 | 50.8 | 2 | 79.4 | 1.6 | |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 42.2 | 56 | 63.5 | 2 | 88.9 | 1.6 | |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 48.3 | 60 | 73 | 2 | 98.4 | 1.6 | |

| 2 | 50 | 150 | 17.5 | 78 | 60.3 | 62 | 92.1 | 2 | 120.7 | 1.6 | |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 73 | 68 | 104.8 | 2 | 139.7 | 1.6 | |

| 3 | 80 | 190 | 22.3 | 108 | 88.9 | 68 | 127 | 2 | 152.4 | 1.6 | |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 101.6 | 70 | 139.7 | 2 | 177.8 | 1.6 | |

| 4 | 100 | 230 | 22.3 | 135 | 114.3 | 75 | 157.2 | 2 | 190.5 | 1.6 | |

| 5 | 125 | 255 | 22.3 | 164 | 141.3 | 87 | 185.7 | 2 | 215.9 | 1.6 | |

| 6 | 150 | 280 | 23.9 | 192 | 168.3 | 87 | 215.9 | 2 | 241.3 | 1.6 | |

| 8 | 200 | 345 | 27 | 246 | 219.1 | 100 | 269.9 | 2 | 298.5 | 1.6 | |

| 10 | 250 | 405 | 28.6 | 305 | 273 | 100 | 323.8 | 2 | 362 | 1.6 | |

| 12 | 300 | 485 | 30.2 | 365 | 323.8 | 113 | 381 | 2 | 431.8 | 1.6 | |

| 14 | 350 | 535 | 33.4 | 400 | 355.6 | 125 | 412.8 | 2 | 476.3 | 1.6 | |

| 16 | 400 | 595 | 35 | 457 | 406.4 | 125 | 469.9 | 2 | 539.8 | 1.6 | |

| 18 | 450 | 635 | 38.1 | 505 | 457.2 | 138 | 533.4 | 2 | 577.9 | 1.6 | |

| 20 | 500 | 700 | 41.3 | 559 | 508 | 143 | 584.2 | 2 | 635 | 1.6 | |

| 24 | 600 | 815 | 46.1 | 663 | 610 | 151 | 692.2 | 2 | 749.3 | 1.6 |

Ubukhulu beFlange Engaboni bekilasi le-150

| Usayizi | Usayizi | Ngaphandle | I-Flange | RF | RF | I-PCD | Inani le | Usayizi we-Bolt | Ibholithi Yomshini | I-RF Stud | Usayizi Wembobo | I-ISO Stud | Isisindo |

| A | B | C | D | E | |||||||||

| 1/2 | 15 | 90 | 9.6 | 34.9 | 2 | 60.3 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.9 |

| 3/4 | 20 | 100 | 11.2 | 42.9 | 2 | 69.9 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 50.8 | 2 | 79.4 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 63.5 | 2 | 88.9 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 73 | 2 | 98.4 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.8 |

| 2 | 50 | 150 | 17.5 | 92.1 | 2 | 120.7 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 104.8 | 2 | 139.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 127 | 2 | 152.4 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 4.1 |

| 3 1/2 | 90 | 215 | 22.3 | 139.7 | 2 | 177.8 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 4 | 100 | 230 | 22.3 | 157.2 | 2 | 190.5 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 7.7 |

| 5 | 125 | 255 | 22.3 | 185.7 | 2 | 215.9 | 8 | 3/4 | 85 | 95 | 7/8 | I-M20 | 9.1 |

| 6 | 150 | 280 | 23.9 | 215.9 | 2 | 241.3 | 8 | 3/4 | 85 | 100 | 7/8 | I-M20 | 11.8 |

| 8 | 200 | 345 | 27 | 269.9 | 2 | 298.5 | 8 | 3/4 | 90 | 110 | 7/8 | I-M20 | 20.5 |

| 10 | 250 | 405 | 28.6 | 323.8 | 2 | 362 | 12 | 7/8 | 100 | 115 | 1 | M24 | 32 |

| 12 | 300 | 485 | 30.2 | 381 | 2 | 431.8 | 12 | 7/8 | 100 | 120 | 1 | M24 | 50 |

| 14 | 350 | 535 | 33.4 | 412.8 | 2 | 476.3 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 64 |

| 16 | 400 | 595 | 35 | 469.9 | 2 | 539.8 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 82 |

| 18 | 450 | 635 | 38.1 | 533.4 | 2 | 577.9 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | I-M30 | 100 |

| 20 | 500 | 700 | 41.3 | 584.2 | 2 | 635 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | I-M30 | 130 |

| 24 | 600 | 815 | 46.1 | 692.2 | 2 | 749.3 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 196 |

Okujwayelekile kanye neBanga

| I-ASME B16.5: Ama-Flanges Amapayipi kanye Nezinto Zokufaka Ezihlanganisiwe | Izinto zokwakha: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

| I-EN 1092-1: Ama-Flanges kanye nama-Joints awo - Ama-Flanges ayindilinga amapayipi, ama-Valve, izinto zokufaka, kanye nezesekeli, i-PN eqokiwe - Ingxenye 1: Ama-Flanges ensimbi | Izinto zokwakha: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe

|

| I-DIN 2501: Ama-Flanges nama-Lapped Joints | Izinto zokwakha: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

| I-GOST 33259: Ama-Flanges ama-Valve, ama-Fittings, nama-Pipelines okucindezela ku-PN 250 | Izinto zokwakha: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

| I-SABS 1123: Ama-Flanges Amapayipi, Amavalvu, kanye Nokufakwa Kwawo | Izinto zokwakha: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

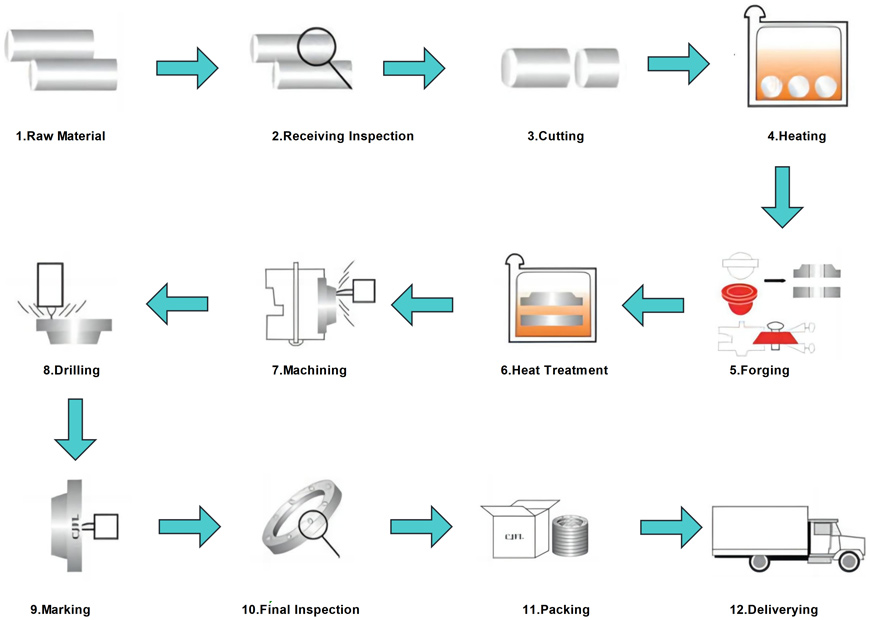

Inqubo Yokukhiqiza

Ikhwalithi yokulawula

Ukuhlola Izinto Ezingavuthiwe, Ukuhlaziywa Kwamakhemikhali, Ukuhlolwa Kwemishini, Ukuhlolwa Okubonakalayo, Ukuhlolwa Kobukhulu, Ukuhlolwa Kokugoba, Ukuhlolwa Kokugoba, Ukuhlolwa Komthelela, Ukuhlolwa Kwe-DWT, Ukuhlolwa Okungonakalisi (UT, MT, PT, X-Ray,), Ukuhlolwa Kokuqina, Ukuhlolwa Kokucindezela, Ukuhlolwa Kokuvuza Kwesihlalo, Ukuhlolwa Kwe-Metallography, Ukuhlolwa Kokugqwala, Ukuhlolwa Kokumelana Nomlilo, Ukuhlolwa Kokufafaza Usawoti, Ukuhlolwa Kokusebenza Kokugeleza, Ukuhlolwa Kwe-Torque and Thrust, Ukuhlolwa Kokupenda Nokumboza, Ukubuyekezwa Kwamadokhumenti…..

Ukusetshenziswa Nokusetshenziswa

Ama-flange ayizingxenye ezibalulekile zezimboni ezisetshenziselwa ukuxhuma amapayipi, ama-valve, imishini kanye nezinye izingxenye zamapayipi. Adlala indima ebalulekile ekuxhumeni, ekusekeleni nasekuvaleni izinhlelo zamapayipi. Ama-flange asebenza njengezingxenye ezibalulekile ezisetshenziswayo ezimbonini ezahlukahlukene, okuhlanganisa:

● Izinhlelo Zokufaka Amapayipi

● Amavalvu

● Imishini

● Ukuxhumana

● Ukuvala

● Ukuphathwa Kwengcindezi

Ukupakisha Nokuthumela

KwaWomic Steel, siyaqonda ukubaluleka kokupakisha okuphephile kanye nokuthunyelwa okuthembekile uma kukhulunywa ngokuletha izinto zethu zokufaka amapayipi ezisezingeni eliphezulu emnyango wakho. Nasi isifinyezo sezinqubo zethu zokupakisha kanye nokuthumela ukuze ubhekisele kuzo:

Ukupakisha:

Ama-flange ethu amapayipi apakishwe ngokucophelela ukuqinisekisa ukuthi afinyelela kuwe esesimweni esifanele, elungele izidingo zakho zezimboni noma zezentengiselwano. Inqubo yethu yokupakisha ifaka phakathi lezi zinyathelo ezibalulekile ezilandelayo:

● Ukuhlolwa Kwekhwalithi: Ngaphambi kokupakisha, wonke ama-flange ahlolwa ngekhwalithi ephelele ukuqinisekisa ukuthi ahlangabezana nezindinganiso zethu eziqinile zokusebenza nobuqotho.

● Ukuvikela: Kuye ngohlobo lwezinto kanye nokusetshenziswa kwazo, ama-flange ethu angathola ukuvikela ukuvimbela ukugqwala kanye nomonakalo ngesikhathi sokuthuthwa.

● Ukubopha Okuphephile: Ama-Flanges ahlanganiswa ndawonye ngokuphephile, okuqinisekisa ukuthi ahlala eqinile futhi evikelekile phakathi nenqubo yokuthumela.

● Ukulebula Nokubhala Imibhalo: Iphakheji ngayinye ibhalwe ngokucacile ngolwazi olubalulekile, okuhlanganisa imininingwane yomkhiqizo, ubuningi, kanye nanoma yimiphi imiyalelo ekhethekile yokuphatha. Imibhalo efanele, njengezitifiketi zokuthobela imithetho, nayo ifakiwe.

● Ukupakisha Ngokwezifiso: Singakwazi ukwamukela izicelo zokupakisha ezikhethekile ngokusekelwe ezidingweni zakho ezihlukile, siqinisekise ukuthi ama-flange akho alungiswa ngendlela efanele.

Ukuthunyelwa:

Sisebenzisana nabalingani bethu bokuthumela impahla abathembekile ukuqinisekisa ukulethwa okuthembekile nokufika ngesikhathi endaweni yakho ecacisiwe. Ithimba lethu lezokuthutha lenza ngcono imizila yokuthumela impahla ukuze linciphise izikhathi zokuhamba futhi linciphise ingozi yokubambezeleka. Ngokuthunyelwa kwamanye amazwe, siphatha yonke imibhalo yamasiko edingekayo kanye nokuhambisana nemithetho ukuze kube lula ukusulwa kwamasiko okushelelayo. Sinikeza izinketho zokuthumela eziguquguqukayo, okuhlanganisa nokuthunyelwa okusheshayo kwempahla ngezidingo eziphuthumayo.