Incazelo Yomkhiqizo

Amapayipi ensimbi ajikelezayo, aziwa nangokuthi amapayipi ensimbi angaphansi komhlaba ahlanganiswe nge-helical submerged arc-welded (HSAW), awuhlobo lwepayipi lensimbi elibonakala ngenqubo yawo yokukhiqiza ehlukile kanye nezakhiwo zawo. Lawa mapayipi asetshenziswa kabanzi ezimbonini ezahlukene ngenxa yamandla awo, ukuqina kwawo, kanye nokuzivumelanisa nezimo. Nansi incazelo eningiliziwe yamapayipi ensimbi ajikelezayo:

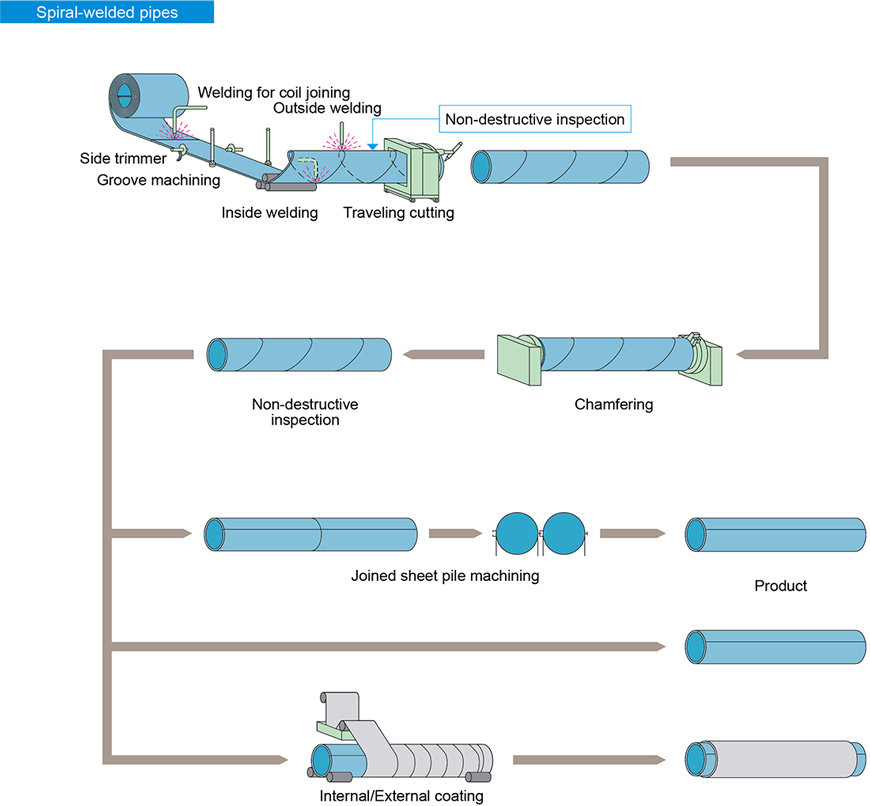

Inqubo Yokukhiqiza:Amapayipi ensimbi ajikelezayo akhiqizwa ngenqubo eyingqayizivele ehilela ukusetshenziswa kwe-coil ye-strip yensimbi. I-strip iyavuleka bese yenziwa ibe yisimo esijikelezayo, bese ishintshwa kusetshenziswa inqubo ye-inferior arc welding (SAW). Le nqubo iphumela kumthungo oqhubekayo, ojikelezayo ubude bepayipi.

Umklamo Wesakhiwo:Umthungo ojikelezayo wamapayipi ensimbi ajikelezayo unikeza amandla angokwemvelo, okwenza afaneleke ukumelana nemithwalo ephezulu kanye nokucindezela. Lo mklamo uqinisekisa ukusatshalaliswa okufanayo kokucindezeleka futhi uthuthukisa ikhono lepayipi lokumelana nokugoba nokuguquka.

Ububanzi Bosayizi:Amapayipi ensimbi ajikelezayo afika ngobubanzi obukhulu (kufika ku-120 Inch) kanye nobukhulu, okuvumela ukuguquguquka ezinhlotsheni ezahlukene zokusebenza. Avame ukutholakala ngobubanzi obukhulu uma kuqhathaniswa nezinye izinhlobo zamapayipi.

Izicelo:Amapayipi ensimbi ajikelezayo asetshenziswa ezimbonini ezahlukahlukene njengowoyela negesi, ukuhlinzekwa kwamanzi, ukwakhiwa, ezolimo, kanye nokuthuthukiswa kwengqalasizinda. Afanele ukusetshenziswa okungaphezu komhlaba kanye nangaphansi komhlaba.

Ukumelana Nokugqwala:Ukuze kuthuthukiswe ubude besikhathi eside, amapayipi ensimbi ajikelezayo avame ukwelashwa ngokulwa nokugqwala. Lokhu kungafaka phakathi ukumbozwa kwangaphakathi nangaphandle, njenge-epoxy, i-polyethylene, ne-zinc, okuvikela amapayipi ezintweni zemvelo nezinto ezigqwalisayo.

Izinzuzo:Amapayipi ensimbi ajikelezayo anikeza izinzuzo eziningana, okuhlanganisa umthamo omkhulu wokuthwala imithwalo, ukusebenza kahle kwezindleko zamapayipi amakhulu, ukulula ukuwafaka, kanye nokumelana nokuguquguquka. Ukwakheka kwawo okugobile kusiza nasekukhipheni amanzi ngendlela ephumelelayo.

I-LongitudinalVSOkujikelezayo:Amapayipi ensimbi ajikelezayo ahlukaniswa namapayipi ahlanganisiwe ngobude ngenqubo yawo yokukhiqiza. Ngenkathi amapayipi ajikelezayo enziwa futhi ahlanganiswa ngobude bepayipi, amapayipi ajikelezayo anomthungo ojikelezayo owakhiwe ngesikhathi sokukhiqiza.

Ikhwalithi yokulawula:Izinqubo zokukhiqiza kanye nokulawula ikhwalithi zibalulekile ekukhiqizeni amapayipi ensimbi ajikelezayo athembekile. Amapharamitha okushisela, i-geometry yamapayipi, kanye nezindlela zokuhlola ziqashwe ngokucophelela ukuqinisekisa ukunamathela ezindinganisweni kanye nemininingwane yemboni.

Amazinga kanye Nemininingwane:Amapayipi ensimbi ajikelezayo akhiqizwa ngokuhambisana nezindinganiso zomhlaba wonke nezemboni ezifana ne-API 5L, ASTM, EN, nezinye. Lezi zindinganiso zichaza izakhiwo zezinto ezibonakalayo, izindlela zokukhiqiza, kanye nezidingo zokuhlola.

Ngamafuphi, amapayipi ensimbi ajikelezayo ayisisombululo esiguquguqukayo nesihlala isikhathi eside sezimboni ezahlukene. Inqubo yawo yokukhiqiza eyingqayizivele, amandla angaphakathi, kanye nokutholakala kwawo ngobukhulu obuhlukene kunegalelo ekusetshenzisweni kwawo kabanzi engqalasizinda, ezokuthutha, amandla, ukwakhiwa kwamachweba nokuningi. Ukukhetha okufanele, ukulawulwa kwekhwalithi, kanye nezinyathelo zokuvikela ukugqwala kudlala indima ebalulekile ekuqinisekiseni ukusebenza kwesikhathi eside kwamapayipi ensimbi ajikelezayo.

Imininingwane

| I-API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| I-ASTM A252: GR.1, GR.2, GR.3 |

| I-EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-ASTM A53/A53M: GR.A, GR.B |

| I-EN 10217: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| I-DIN 2458: St37.0, St44.0, St52.0 |

| I-AS/NZS 1163: Ibanga C250 , Ibanga C350, Ibanga C450 |

| I-GB/T 9711: L175, L210, L245, L290, L320, L360, L390, L415, L450, L485 |

| I-ASTMA671: CA55/CB70/CC65, CB60/CB65/CB70/CC60/CC70, CD70/CE55/CE65/CF65/CF70, CF66/CF71/CF72/CF73, CG100/CH100/CI100/CJ100 |

| Ububanzi(mm) | Ubukhulu bodonga (mm) | |||||||||||||||||||

| 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | |

| 219.1 | ● | ● | ● | ● | ||||||||||||||||

| 273 | ● | ● | ● | ● | ● | |||||||||||||||

| 323.9 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 325 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 355.6 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 377 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 406.4 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 426 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 457 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 478 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 508 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 529 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 630 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| 711 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 720 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 813 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| 820 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| 920 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 1020 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 1220 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 1420 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 1620 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| 1820 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2020 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2220 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2500 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 2540 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 3000 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

Ukubekezelela Ububanzi Bangaphandle Nobukhulu Bodonga

| Okujwayelekile | Ukubekezelela Umzimba Wepayipi | Ukubekezelelana Kwesiphetho Sepayipi | Ukubekezelela Ubukhulu Bodonga | |||

| Ububanzi obungaphandle | Ukubekezelelana | Ububanzi obungaphandle | Ukubekezelelana | |||

| GB/T3091 | OD≤48.3mm | ≤±0.5 | OD≤48.3mm | - | ≤±10% | |

| 48.3 | ≤±1.0% | 48.3 | - | |||

| 273.1 | ≤±0.75% | 273.1 | -0.8~+2.4 | |||

| OD>508mm | ≤±1.0% | OD>508mm | -0.8~+3.2 | |||

| GB/T9711.1 | OD≤48.3mm | -0.79~+0.41 | - | - | OD≤73 | -12.5%~+20% |

| 60.3 | ≤±0.75% | OD≤273.1mm | -0.4~+1.59 | 88.9≤OD≤457 | -12.5%~+15% | |

| 508 | ≤±1.0% | OD≥323.9 | -0.79~+2.38 | OD≥508 | -10.0%~+17.5% | |

| OD>941mm | ≤±1.0% | - | - | - | - | |

| GB/T9711.2 | 60 | ±0.75%D~±3mm | 60 | ±0.5%D~±1.6mm | 4mm | ±12.5%T~±15.0%T |

| 610 | ±0.5%D~±4mm | 610 | ±0.5%D~±1.6mm | Isisindo ≥25mm | -3.00mm~+3.75mm | |

| OD>1430mm | - | OD>1430mm | - | - | -10.0%~+17.5% | |

| I-SY/T5037 | OD<508mm | ≤±0.75% | OD<508mm | ≤±0.75% | OD<508mm | ≤±12.5% |

| OD≥508mm | ≤±1.00% | OD≥508mm | ≤±0.50% | OD≥508mm | ≤±10.0% | |

| I-API 5L PSL1/PSL2 | OD <60.3 | -0.8mm~+0.4mm | OD≤168.3 | -0.4mm~+1.6mm | Isisindo≤5.0 | ≤±0.5 |

| 60.3≤OD≤168.3 | ≤±0.75% | 168.3 | ≤±1.6mm | 5.0 | ≤±0.1T | |

| 168.3 | ≤±0.75% | 610 | ≤±1.6mm | T≥15.0 | ≤±1.5 | |

| 610 | ≤±4.0mm | OD>1422 | - | - | - | |

| OD>1422 | - | - | - | - | - | |

| I-API 5CT | OD<114.3 | ≤±0.79mm | OD<114.3 | ≤±0.79mm | ≤-12.5% | |

| OD≥114.3 | -0.5%~1.0% | OD≥114.3 | -0.5%~1.0% | ≤-12.5% | ||

| I-ASTM A53 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

| I-ASTM A252 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

| DN mm | NB Intshi | OD mm | I-SCH40S mm | I-SCH5S mm | I-SCH10S mm | I-SCH10 mm | I-SCH20 mm | I-SCH40 mm | I-SCH60 mm | I-XS/80S mm | I-SCH80 mm | I-SCH100 mm | I-SCH120 mm | I-SCH140 mm | I-SCH160 mm | I-SCHXXS mm |

| 6 | 1/8” | 10.29 | 1.24 | 1.73 | 2.41 | |||||||||||

| 8 | 1/4” | 13.72 | 1.65 | 2.24 | 3.02 | |||||||||||

| 10 | 3/8” | 17.15 | 1.65 | 2.31 | 3.20 | |||||||||||

| 15 | 1/2” | 21.34 | 2.77 | 1.65 | 2.11 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | 3/4” | 26.67 | 2.87 | 1.65 | 2.11 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 1” | 33.40 | 3.38 | 1.65 | 2.77 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | 1 1/4” | 42.16 | 3.56 | 1.65 | 2.77 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | ||||||

| 40 | 1 1/2” | 48.26 | 3.68 | 1.65 | 2.77 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | 2” | 60.33 | 3.91 | 1.65 | 2.77 | 3.91 | 5.54 | 5.54 | 9.74 | 11.07 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | ||||||

| 80 | 3” | 88.90 | 5.49 | 2.11 | 3.05 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | ||||||

| 90 | 3 1/2” | 101.60 | 5.74 | 2.11 | 3.05 | 5.74 | 8.08 | 8.08 | ||||||||

| 100 | 4” | 114.30 | 6.02 | 2.11 | 3.05 | 6.02 | 8.56 | 8.56 | 11.12 | 13.49 | 17.12 | |||||

| 125 | 5” | 141.30 | 6.55 | 2.77 | 3.40 | 6.55 | 9.53 | 9.53 | 12.70 | 15.88 | 19.05 | |||||

| 150 | 6” | 168.27 | 7.11 | 2.77 | 3.40 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8” | 219.08 | 8.18 | 2.77 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 19.26 | 20.62 | 23.01 | 22.23 | |

| 250 | 10” | 273.05 | 9.27 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 | 12.70 | 15.09 | 19.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 300 | 12” | 323.85 | 9.53 | 3.96 | 4.57 | 6.35 | 10.31 | 14.27 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 350 | 14” | 355.60 | 9.53 | 3.96 | 4.78 | 6.35 | 7.92 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16” | 406.40 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 12.70 | 16.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |

| 450 | 18” | 457.20 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20” | 508.00 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |

| 550 | 22” | 558.80 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24” | 609.60 | 9.53 | 5.54 | 6.35 | 6.35 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26” | 660.40 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 700 | 28” | 711.20 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 750 | 30” | 762.00 | 9.53 | 6.35 | 7.92 | 7.92 | 12.70 | 12.70 | ||||||||

| 800 | 32” | 812.80 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 850 | 34” | 863.60 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 900 | 36” | 914.40 | 9.53 | 7.92 | 12.70 | 19.05 | 12.70 | |||||||||

| I-DN 1000mm nangaphezulu Ububanzi bodonga lwepayipi Ubukhulu obuphezulu 25mm | ||||||||||||||||

Okujwayelekile kanye neBanga

| Okujwayelekile | Amabanga Ensimbi |

| I-API 5L: Imininingwane yepayipi yomugqa | GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| I-ASTM A252: Imininingwane Ejwayelekile Yamapayipi Ensimbi Ahlanganisiwe Nangenamthungo | GR.1, GR.2, GR.3 |

| I-EN 10219-1: Izingxenye Ezingenalutho Ezihlanganisiwe Ezibunjiwe Zesakhiwo Esingena-alloy Nezinhlayiya Ezinhle | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-EN10210: Izingxenye Ezingenalutho Eziqediwe Zesakhiwo Ezingena-Alloy Nezinhlayiya Ezinhle | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-ASTM A53/A53M: Ipayipi, Insimbi, Emnyama futhi Ecwiliswe Ngokushisayo, Embozwe Ngezinki, Ehlanganisiwe Futhi Engenamthungo | GR.A, GR.B |

| EN 10217: Amapayipi Ensimbi Ahlanganisiwe Ngezinhloso Zokucindezela | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| I-DIN 2458: Amapayipi Nezipayipi Zensimbi Ezihlanganisiwe | St37.0, St44.0, St52.0 |

| I-AS/NZS 1163: Izinga lase-Australia/laseNew Zealand lezingxenye zensimbi ezakhiwe ngendlela ebandayo | Ibanga C250 , Ibanga C350 , Ibanga C450 |

| GB/T 9711: Izimboni Zikaphethiloli Negesi Yemvelo - Ipayipi Lensimbi Lamapayipi | L175, L210, L245, L290, L320 , L360, L390 , L415, L450 , L485 |

| I-AWWA C200: Ipayipi Lamanzi Lensimbi Eliyi-intshi eziyi-6 (150 mm) Nelikhulu | Insimbi Yekhabhoni |

Inqubo Yokukhiqiza

Ikhwalithi yokulawula

● Ukuhlola Izinto Ezingavuthiwe

● Ukuhlaziywa Kwamakhemikhali

● Ukuhlolwa Kwemishini

● Ukuhlolwa Okubonakalayo

● Ukuhlola Ubukhulu

● Ukuhlolwa Kokugoba

● Ukuhlolwa Komthelela

● Ukuhlolwa Kokugqwala Okuphakathi Kwezinhlayiya

● Ukuhlolwa Okungabhubhisi (UT, MT, PT)

● Iziqu Zenqubo Yokushisela

● Ukuhlaziywa kwesakhiwo esincane

● Ukuhlolwa Kokuvutha Nokuthamba

● Ukuhlolwa Kokuqina

● Ukuhlolwa Kokucindezeleka

● Ukuhlolwa kwe-Metallography

● Ukuhlolwa Kokugqwala

● Ukuhlolwa Kwamanje kwe-Eddy

● Ukuhlolwa Kokupenda Nokumboza

● Ukubuyekezwa Kwamadokhumenti

Ukusetshenziswa Nokusetshenziswa

Amapayipi ensimbi ajikelezayo asetshenziswa ngezindlela eziningi futhi asetshenziswa kabanzi ezimbonini ezahlukene ngenxa yezici zawo ezihlukile kanye nezinzuzo. Akhiwa ngokuhlanganisa imichilo yensimbi ndawonye ukuze kudalwe ipayipi elinomthungo ojikelezayo oqhubekayo. Nazi ezinye zezindlela ezivamile zokusebenzisa amapayipi ensimbi ajikelezayo:

● Ukuthuthwa Okunoketshezi: Lawa mapayipi ahambisa amanzi, uwoyela, kanye negesi kahle amabanga amade emapayipini ngenxa yokwakheka kwawo okungenamthungo kanye namandla aphezulu.

● Uwoyela negesi: Kubalulekile ezimbonini zikawoyela negesi, bathutha uwoyela ongahluziwe, igesi yemvelo, kanye nemikhiqizo ecolisisiwe, bekhonza izidingo zokuhlola nokusabalalisa.

● Ukufaka inqwaba: Izinqwaba zesisekelo kumaphrojekthi okwakha zisekela imithwalo esindayo ezakhiweni ezifana nezakhiwo namabhuloho.

● Ukusetshenziswa Kwesakhiwo: Njengoba zisetshenziswa ezakhiweni, ezinsikeni nasezisekelweni, ukuqina kwazo kunegalelo ekuzinzeni kwesakhiwo.

● Ama-Culvert kanye Nokukhipha Amanzi: Asetshenziswa ezinhlelweni zamanzi, ukumelana kwawo nokugqwala kanye nengaphakathi elibushelelezi kuvimbela ukuvaleka futhi kuthuthukisa ukugeleza kwamanzi.

● Amapayipi Omshini: Ezokukhiqiza kanye nezolimo, la mapayipi ahlinzeka ngezixazululo ezingabizi kakhulu neziqinile zezingxenye.

● Imikhumbi Yasolwandle Nasogwini: Ezindaweni ezinzima, zisetshenziswa emapayipini angaphansi kwamanzi, ezisekelweni zasogwini, kanye nasekwakhiweni kwezindawo zokungenisa amanzi.

● Ukumba: Zithwala izinto zokwakha kanye nodaka emisebenzini yokumba enzima ngenxa yokwakhiwa kwazo okuqinile.

● Ukuhlinzekwa Kwamanzi: Kulungele amapayipi amakhulu obubanzi ezinhlelweni zamanzi, okuthutha kahle umthamo wamanzi omningi.

● Izinhlelo Zokushisa Komhlaba: Ezisetshenziswa kumaphrojekthi wamandla okushisa komhlaba, zisingatha ukudluliselwa koketshezi olungangeni ukushisa phakathi kwamachibi nezitshalo zikagesi.

Uhlobo oluguquguqukayo lwamapayipi ensimbi ajikelezayo, kuhlanganiswe namandla awo, ukuqina, kanye nokuzivumelanisa nezimo, kuwenza abe yingxenye ebalulekile kuzo zonke izimboni nezinhlelo zokusebenza ezahlukahlukene.

Ukupakisha Nokuthumela

Ukupakisha:

Inqubo yokupakisha amapayipi ensimbi ajikelezayo ihilela izinyathelo eziningana ezibalulekile ukuqinisekisa ukuthi amapayipi avikelwe ngokwanele ngesikhathi sokuthuthwa nokugcinwa kwawo:

● Ukubopha Amapayipi: Amapayipi ensimbi ajikelezayo avame ukuhlanganiswa ndawonye kusetshenziswa izintambo, amabhande ensimbi, noma ezinye izindlela zokubopha eziqinile. Ukubopha kuvimbela amapayipi ngamanye ukuthi angahambi noma ashintshe ngaphakathi kwephakheji.

● Ukuvikelwa Kweziphetho Zepayipi: Izivalo zepulasitiki noma izembozo zokuvikela zifakwa kuzo zombili iziphetho zamapayipi ukuvimbela umonakalo eziphethweni zepayipi kanye nobuso bangaphakathi.

● Ukuvimbela Ukungenwa Kwamanzi: Amapayipi asongwa ngezinto ezingangenwa ngamanzi, njengezingqwembe zepulasitiki noma ukugoqa, ukuze avikeleke emswakama ngesikhathi sokuthuthwa, ikakhulukazi ekuthuthweni ngaphandle noma olwandle.

● Ukugoqa: Izinto ezengeziwe zokugoqa, njengezifakelo ze-foam noma izinto zokugoqa, zingase zengezwe phakathi kwamapayipi noma ezindaweni ezisengozini ukuze zimunce ukushaqeka nokudlidliza.

● Ukulebula: Inqwaba ngayinye ilebula ngolwazi olubalulekile, okuhlanganisa imininingwane yepayipi, ubukhulu, ubuningi, kanye nendawo okuyosetshenziswa kuyo. Lokhu kusiza ekutholeni nasekuphatheni kalula.

Ukuthunyelwa:

● Ukuthunyelwa kwamapayipi ensimbi ajikelezayo kudinga ukuhlela ngokucophelela ukuqinisekisa ukuthuthwa okuphephile nokuphumelelayo:

● Imodi Yezokuthutha: Ukukhetha imodi yezokuthutha (umgwaqo, isitimela, ulwandle, noma umoya) kuncike ezicini ezifana nebanga, ukuphuthuma, kanye nokufinyeleleka kwendawo oya kuyo.

● Ukufakwa kwezitsha: Amapayipi angafakwa ezitsheni zokuthumela ezijwayelekile noma ezitsheni ezikhethekile ezibekwe ngendlela eyisicaba. Ukufakwa kwezitsha kuvikela amapayipi ezintweni zangaphandle futhi kunikeza indawo elawulwayo.

● Ukuvikela: Amapayipi aqiniswa ngaphakathi kweziqukathi kusetshenziswa izindlela ezifanele zokubopha, njengokubopha, ukuvimba, kanye nokubhanqa. Lokhu kuvimbela ukunyakaza futhi kunciphisa ingozi yomonakalo ngesikhathi sokuhamba.

● Amadokhumenti: Amadokhumenti anembile, kufaka phakathi ama-invoyisi, uhlu lokupakisha, kanye nemibhalo yokuthumela, alungiselelwe izinjongo zokuhlanza izimpahla kanye nokulandelela.

● Umshwalense: Umshwalense wempahla uvame ukutholakala ukuze umboze ukulahlekelwa noma umonakalo ongaba khona ngesikhathi sokuthutha.

● Ukuqapha: Kuyo yonke inqubo yokuthumela, amapayipi angalandelelwa kusetshenziswa i-GPS nezinhlelo zokulandelela ukuqinisekisa ukuthi asendleleni efanele kanye neshejuli efanele.

● Ukuvunyelwa Kwempahla Engenayo: Kunikezwa amadokhumenti afanele ukuze kube lula ukuvunyelwa kwempahla engaphandle kwetheku noma emngceleni wendawo oya kuyo.

Isiphetho:

Ukupakisha kahle kanye nokuthunyelwa kwamapayipi ensimbi ajikelezayo kubalulekile ukuze kulondolozwe ikhwalithi nobuqotho bamapayipi ngesikhathi sokuthuthwa. Ukulandela imikhuba emihle embonini kuqinisekisa ukuthi amapayipi afika lapho eya khona esesimweni esihle kakhulu, elungele ukufakwa noma ukucutshungulwa okuqhubekayo.