Incazelo Yomkhiqizo

Ukufakwa kwebhokisi kanye namapayipi okusetshenziswa kabanzi ku-oyela negesi kuyaqhubeka, ukufakwa kwebhokisi kanye namapayipi kuyizinto ezibalulekile embonini kawoyela negesi ezisetshenziselwa ukukhipha kanye nokuthuthwa kwama-hydrocarbon (oyela negesi yemvelo) kusuka emachibini angaphansi komhlaba kuya phezulu. Zidlala indima ebalulekile ekuqinisekiseni ukuphepha, ubuqotho, kanye nokusebenza kahle kwemisebenzi yokubhoboza kanye nokukhiqiza.

Ipayipi iwuhlobo lwepayipi elisetshenziselwa ukudlulisa uwoyela ongahluziwe kanye negesi yemvelo kusuka kungqimba kawoyela noma ungqimba lwegesi kuya phansi ngemva kokuba ukubhoboza sekuqediwe. Ithini lepayipi livumela ingcindezi ekhiqizwa ngesikhathi senqubo yokukhipha. Ipayipi likhiqizwa ngendlela efanayo nebhokisi, kodwa inqubo ebizwa ngokuthi "ukucasula" iyadingeka futhi ukuze kuqiniswe ipayipi lepayipi.

Ibhokisi lisetshenziselwa ukuvikela imigodi eye yambiwa emhlabathini ukuze kufuywe uwoyela. Njengoba isetshenziswa njengepayipi lokubhoboza, amapayipi okufaka imigodi yamafutha nawo avumela ukucindezeleka kwe-axial tension, ngakho-ke kudingeka insimbi enamandla aphezulu esezingeni eliphezulu. Amabhokisi e-OCTG angamapayipi amakhulu anobubanzi afakwe ukhonkolo emgodini.

Imininingwane

| I-API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| I-API 5CT: J55, K55, N80, L80, P110 |

| I-API 5D: E75, X95, G105, S135 |

| I-EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-ASTM A106: GR.A, GR.B, GR.C |

| I-ASTM A53/A53M: GR.A, GR.B |

| I-ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| I-ASTM A333: Ibanga 1, Ibanga 3, Ibanga 4, Ibanga 6, Ibanga 7, Ibanga 8, Ibanga 9. Ibanga 10, Ibanga 11 |

| I-DIN 2391: St30Al, St30Si, St35, St45, St52 |

| I-DIN EN 10216-1: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| I-JIS G3454: STPG 370, STPG 410 |

| I-JIS G3456: STPT 370, STPT 410, STPT 480 |

| I-GB/T 8163: 10#, 20#, Q345 |

| I-GB/T 8162: 10#, 20#, 35#, 45#, Q345 |

Uhlu lwe-ISO/API Steel Casing

| Amalebulaa | Ngaphandle ububanzi D mm | Okuqanjiwe okuqondile isisindob, c Imigomo nemibandela kg/m | Udonga ukujiya t mm | Uhlobo lokuphela kokuphela | ||||||||

| 1 | 2 | H40 | J55 K55 | I-M65 | L80 I-C95 | I-N80 Uhlobo 1, Q | I-C90 I-T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 9.50 10.50 11.60 13.50 15.10 | 114,30 114,30 114,30 114,30 114,30 | 14,14 15,63 17,26 20,09 22,47 | 5,21 5,69 6,35 7,37 8,56 | PS — — — — | PS I-PSB I-PSLB — — | PS I-PSB I-PLB I-PLB — | — — I-PLB I-PLB — | — — I-PLB I-PLB — | — — I-PLB I-PLB — | — — I-PLB I-PLB I-PLB | — — — — I-PLB |

| 5 5 5 5 5 5 5 | 11.50 13.00 15.00 18.00 21.40 23.20 24.10 | 127,00 127,00 127,00 127,00 127,00 127,00 127,00 | 17,11 19,35 22,32 26,79 31,85 34,53 35,86 | 5,59 6,43 7,52 9,19 11,10 12,14 12,70 | — — — — — — — | PS I-PSLB I-PSLBE — — — — | PS I-PSLB I-PLB I-PLB I-PLB — — | — — I-PLBE I-PLBE I-PLB I-PLB I-PLB | — — I-PLBE I-PLBE I-PLB I-PLB I-PLB | — — I-PLBE I-PLBE I-PLB I-PLB I-PLB | — — I-PLBE I-PLBE I-PLB I-PLB I-PLB | — — — I-PLBE I-PLB I-PLB I-PLB |

| 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 | 14.00 15.50 17.00 20.00 23.00 26.80 29.70 32.60 35.30 38.00 40.50 43.10 | 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 | 20,83 23,07 25,30 29,76 34,23 39,88 44,20 48,51 52,53 56,55 60,27 64,14 | 6,20 6,98 7,72 9,17 10,54 12,70 14,27 15,88 17,45 19,05 20,62 22,22 | PS | PS I-PSLBE I-PSLBE | PS I-PSLB I-PLB I-PLB I-PLB | — — I-PLBE I-PLBE I-PLBE — — — — — — — | I-PLBE I-PLBE I-PLBE | I-PLBE I-PLBE I-PLBE P P P P P P P | I-PLBE I-PLBE I-PLBE | — — — — I-PLBE — — — — — — |

| 6-5/8 6-5/8 6-5/8 6-5/8 | 20.00 24.00 28.00 32.00 | 168,28 168,28 168,28 168,28 | 29,76 35,72 41,67 47,62 | 7,32 8,94 10,59 12,06 | PS — — | I-PSLB I-PSLBE — | I-PSLB I-PLB I-PLB — | — I-PLBE I-PLBE I-PLBE | — I-PLBE I-PLBE I-PLBE | — I-PLBE I-PLBE I-PLBE | — I-PLBE I-PLBE I-PLBE | — — I-PLBE |

| 7 7 7 7 7 7 7 7 7 7 7 7 7 | 17.00 20.00 23.00 26.00 29.00 32.00 35.00 38.00 42.70 46.40 50.10 53.60 57.10 | 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 | 25,30 29,76 34,23 38,69 43,16 47,62 52,09 56,55 63,54 69,05 74,56 79,77 84,97 | 5,87 6,91 8,05 9,19 10,36 11,51 12,65 13,72 15,88 17,45 19,05 20,62 22,22 | PS PS — — — — — — — — — — — | — PS I-PSLBE I-PSLBE — — — — — — — — — | — PS I-PLB I-PLB I-PLB I-PLB — — — — — — — | — — I-PLBE I-PLBE I-PLBE I-PLBE I-PLBE I-PLBE — — — — — | — — I-PLBE I-PLBE I-PLBE I-PLBE I-PLBE I-PLBE — — — — — | — — I-PLBE I-PLBE I-PLBE I-PLBE I-PLBE I-PLBE P P P P P | — — — I-PLBE I-PLBE I-PLBE I-PLBE I-PLBE — — — — — | — — — — — — I-PLBE I-PLBE — — — — — |

| Bheka amanothi ekugcineni kwethebula. | ||||||||||||

| Amalebulaa | Ngaphandle ububanzi D mm | Okuqanjiwe okuqondile isisindob, c Imigomo nemibandela kg/m | Udonga ukujiya t mm | Uhlobo lokuphela kokuphela | ||||||||

| 1 | 2 | H40 | J55 K55 | I-M65 | L80 I-C95 | I-N80 Uhlobo 1, Q | I-C90 I-T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 | 24.00 26.40 29.70 33.70 39.00 42.80 45.30 47.10 51.20 55.30 | 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 | 35,72 39,29 44,20 50,15 58,04 63,69 67,41 70,09 76,19 82,30 | 7,62 8,33 9,52 10,92 12,70 14,27 15,11 15,88 17,45 19,05 | PS | I-PSLBE | I-PSLB I-PLB I-PLB | I-PLBE I-PLBE I-PLBE I-PLBE I-PLB I-PLB I-PLB | I-PLBE I-PLBE I-PLBE I-PLBE I-PLB I-PLB I-PLB | I-PLBE I-PLBE I-PLBE I-PLBE I-PLB I-PLB I-PLB P P | I-PLBE I-PLBE I-PLBE I-PLB I-PLB I-PLB | I-PLBE I-PLB I-PLB I-PLB |

| 7-3/4 | 46.10 | 19,685 | 6,860 | 1,511 | — | — | — | P | P | P | P | P |

| 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 | 24.00 28.00 32.00 36.00 40.00 44.00 49.00 | 219,08 219,08 219,08 219,08 219,08 219,08 219,08 | 35,72 41,67 47,62 53,57 59,53 65,48 72,92 | 6,71 7,72 8,94 10,16 11,43 12,70 14,15 | PS PS — — — — | PS — I-PSLBE I-PSLBE — — — | PS PS I-PSLB I-PSLB I-PLB — — | — — — I-PLBE I-PLBE I-PLBE I-PLBE | — — — I-PLBE I-PLBE I-PLBE I-PLBE | — — — I-PLBE I-PLBE I-PLBE I-PLBE | — — — — I-PLBE I-PLBE I-PLBE | — — — — — — I-PLBE |

| 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 | 32.30 36.00 40.00 43.50 47.00 53.50 58.40 59.40 64.90 70.30 75.60 | 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 | 48,07 53,57 59,53 64,73 69,94 79,62 86,91 88,40 96,58 104,62 112,50 | 7,92 8,94 10,03 11,05 11,99 13,84 15,11 15,47 17,07 18,64 20,24 | PS PS — — — — — — — — — | — I-PSLB I-PSLBE — — — — — — — — | — I-PSLB I-PSLB I-PLB I-PLB — — — — — — | — — I-PLBE I-PLBE I-PLBE I-PLBE I-PLB — — — — | — — I-PLBE I-PLBE I-PLBE I-PLBE I-PLB — — — — | — — I-PLBE I-PLBE I-PLBE I-PLBE I-PLB P P P P | — — — I-PLBE I-PLBE I-PLBE I-PLB — — — — | — — — — I-PLBE I-PLBE I-PLB — — — — |

| 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 | 32.75 40.50 45.50 51.00 55.50 60.70 65.70 73.20 79.20 85.30 | 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 | 48,74 60,27 67,71 75,90 82,59 90,33 97,77 108,93 117,86 126,94 | 7,09 8,89 10,16 11,43 12,57 13,84 15,11 17,07 18,64 20,24 | PS PS | I-PSB I-PSBE I-PSBE | I-PSB I-PSB I-PSB I-PSB | I-PSBE I-PSBE | I-PSBE I-PSBE | I-PSBE I-PSBE I-PSBE I-PSB P P P | I-PSBE I-PSBE I-PSBE I-PSB | I-PSBE I-PSB |

| 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 | 42.00 47.00 54.00 60.00 65.00 71.00 | 298,45 298,45 298,45 298,45 298,45 298,45 | 62,50 69,94 80,36 89,29 96,73 105,66 | 8,46 9,53 11,05 12,42 13,56 14,78 | PS — — — | I-PSB I-PSB I-PSB — — | I-PSB I-PSB I-PSB — — | — — I-PSB P P | — — I-PSB P P | — — I-PSB P P | — — I-PSB P P | — — I-PSB P P |

| 13-3/8 13-3/8 13-3/8 13-3/8 13-3/8 | 48.00 54.50 61.00 68.00 72.00 | 339,72 339,72 339,72 339,72 339,72 | 71,43 81,10 90,78 101,19 107,15 | 8,38 9,65 10,92 12,19 13,06 | PS — — — — | — I-PSB I-PSB I-PSB — | — I-PSB I-PSB I-PSB — | — — — I-PSB I-PSB | — — — I-PSB I-PSB | — — — I-PSB I-PSB | — — — I-PSB I-PSB | — — — — I-PSB |

| Bheka amanothi ekugcineni kwethebula. | ||||||||||||

| Amalebulaa | Ngaphandle ububanzi D mm | Okuqanjiwe okuqondile isisindob, c Imigomo nemibandela kg/m | Udonga ukujiya t mm | Uhlobo lokuphela kokuphela | ||||||||

| 1 | 2 | H40 | J55 K55 | I-M65 | L80 I-C95 | I-N80 Uhlobo 1, Q | I-C90 I-T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 16 16 16 16 | 65.00 75.00 84.00 109.00 | 406,40 406,40 406,40 406,40 | 96,73 111,61 125,01 162,21 | 9,53 11,13 12,57 16,66 | PS | I-PSB I-PSB P | I-PSB I-PSB | P | P | P | P | |

| 18-5/8 | 87.50 | 47,308 | 13,021 | 1,105 | PS | I-PSB | I-PSB | — | — | — | — | — |

| 20 20 20 | 94.00 106.50 133.00 | 508,00 508,00 508,00 | 139,89 158,49 197,93 | 11,13 12,70 16,13 | I-PSL — — | I-PSLB I-PSLB I-PSLB | I-PSLB I-PSLB — | — — — | — — — | — — — | — — — | — — — |

| P = Isiphetho esilula, S = Intambo emfushane eyindilinga, L = Intambo ende eyindilinga, B = Intambo ye-Buttress, E = Umugqa ogqamile. | ||||||||||||

| ♦ Amalebula enzelwe ulwazi kanye nosizo eku-odeni. ♦ Izisindo eziqondile eziqondile, ezifakwe intambo nezihlanganisiwe (ikholomu 2) ziboniswa ngolwazi kuphela. ♦ Ubuningi bezinsimbi ze-martensitic chromium (izinhlobo ze-L80 9Cr kanye ne-13Cr) zihlukile kwezinsimbi ze-carbon. Ngakho-ke, ubuningi obubonisiwe abunembile ngezinsimbi ze-martensitic chromium. Kungasetshenziswa i-mass correction factor engu-0,989. | ||||||||||||

| Amalebula | Ububanzi bangaphandle D mm | Umugqa oqondile ophelele isisindo kg/m | Ubukhulu bodonga t mm | |

| 1 | 2 | |||

| 1 | 2 | 3 | 4 | 5 |

| 3-1/2 4 4-1/2 5 5-1/2 6-5/8 | 9.92 11.35 13.05 17.95 19.83 27.66 | 88,90 101,60 114,30 127,00 139,70 168,28 | 14,76 16,89 19,42 26,71 29,51 41,18 | 7,34 7,26 7,37 9,19 9,17 10,59 |

Uhlu lwe-ISO/API Steel Tubing

| Amalebula | Ngaphandle ububanzi D mm | Okuqondile okujwayelekile izixukua, b | Udonga obukhulu- ukuqina t mm | Uhlobo lokuphela kokuphelac | |||||||||||

| Okungewona- dumela Imigomo nemibandela kg/m | Isengezo. dumela Imigomo nemibandela kg/m | Integ. ilunga kg/m | |||||||||||||

| 1 | 2 | ||||||||||||||

| NU Imigomo nemibandela | EU Imigomo nemibandela | IJ | H40 | J55 | L80 | I-N80 Uhlobo 1, Q | I-C90 | I-T95 | P110 | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1.900 1.900 1.900 1.900 1.900 | 2.40 2.75 3.65 4.42 5.15 | — 2.90 3.73 — — | 2.40 2.76 — — — | 48,26 48,26 48,26 48,26 48,26 | — 4,09 5,43 6,58 7,66 | — 4,32 5,55 — — | 3,57 4,11 — — — | 3,18 3,68 5,08 6,35 7,62 | PI I-PNUI PU — — | PI I-PNUI PU — — | — I-PNUI PU P P | — I-PNUI PU — — | — I-PNUI PU P P | — I-PNUI PU P P | PU — — |

| 2.063 2.063 | 3.24 4.50 | — — | 3.25 — | 52,40 52,40 | — — | — — | 4,84 — | 3,96 5,72 | PI P | PI P | PI P | PI P | PI P | PI P | P |

| 2-3/8 2-3/8 2-3/8 2-3/8 2-3/8 | 4.00 4.60 5.80 6.60 7.35 | 4.70 5.95 7.45 | 60,32 60,32 60,32 60,32 60,32 | 5,95 6,85 8,63 9,82 10,94 | 6,99 8,85 11,09 | 4,24 4,83 6,45 7,49 8,53 | PN I-PNU | PN I-PNU | PN I-PNU I-PNU P PU | PN I-PNU I-PNU — — | PN I-PNU I-PNU P PU | PN I-PNU I-PNU P PU | I-PNU I-PNU | ||

| 2-7/8 2-7/8 2-7/8 2-7/8 | 6.40 7.80 8.60 9.35 | 6.50 7.90 8.70 9.45 | — — — | 73,02 73,02 73,02 73,02 | 9,52 11,61 12,80 13,91 | 9,67 11,76 12,95 14,06 | — — — | 5,51 7,01 7,82 8,64 | I-PNU — — | I-PNU — — | I-PNU I-PNU I-PNU PU | I-PNU I-PNU I-PNU — | I-PNU I-PNU I-PNU PU | I-PNU I-PNU I-PNU PU | I-PNU I-PNU I-PNU — |

| 2-7/8 2-7/8 | 10.50 11.50 | — | — | 73,02 73,02 | 15,63 17,11 | — | — | 9,96 11,18 | — | — | P P | — | P P | P P | — |

| 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 | 7.70 9.20 10.20 12.70 14.30 15.50 17.00 | — 9.30 — 12.95 — — — | — — — — — — — | 88,90 88,90 88,90 88,90 88,90 88,90 88,90 | 11,46 13,69 15,18 18,90 21,28 23,07 25,30 | — 13,84 — 19,27 — — — | — — — — — — — | 5,49 6,45 7,34 9,52 10,92 12,09 13,46 | PN I-PNU PN — — — — | PN I-PNU PN — — — — | PN I-PNU PN I-PNU P P P | PN I-PNU PN I-PNU — — — | PN I-PNU PN I-PNU P P P | PN I-PNU PN I-PNU P P P | — I-PNU — I-PNU — — — |

| 4 4 4 4 4 4 | 9.50 10.70 13.20 16.10 18.90 22.20 | — 11.00 — — — — | — — — — — — | 101,60 101,60 101,60 101,60 101,60 101,60 | 14,14 — 19,64 23,96 28,13 33,04 | — 16,37 — — — — | — — — — — — | 5,74 6,65 8,38 10,54 12,70 15,49 | PN PU — — — — | PN PU — — — — | PN PU P P P P | PN PU — — — — | PN PU P P P P | PN PU P P P P | — — — — — — |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 12.60 15.20 17.00 18.90 21.50 23.70 26.10 | 12.75 | 114,30 114,30 114,30 114,30 114,30 114,30 114,30 | 18,75 22,62 25,30 28,13 32,00 35,27 38,84 | 18,97 | 6,88 8,56 9,65 10,92 12,70 14,22 16,00 | I-PNU | I-PNU | I-PNU P P P P P P | I-PNU — — — — — — | I-PNU P P P P P P | I-PNU P P P P P P | |||

| P = Isiphetho esilula, N = Intambo engaphazamiseki futhi ehlanganisiwe, U = Intambo yangaphandle ephazamisekile futhi ehlanganisiwe, I = Ilunga elihlanganisiwe. | |||||||||||||||

| ♦ Izinqwaba eziqondile, imicu kanye nokuxhumanisa (ikholomu 2, 3, 4) kuboniswa ngolwazi kuphela. ♦ Ubuningi bezinsimbi ze-martensitic chromium (izinhlobo ze-L80 9Cr kanye ne-13Cr) zihlukile kwezinsimbi ze-carbon. Ngakho-ke, ubuningi obubonisiwe abunembile ngezinsimbi ze-martensitic chromium. Kungasetshenziswa i-mass correction factor engu-0,989. ♦ Amapayipi angaphazamiseki ayatholakala ngama-coupling avamile noma ama-coupling akhethekile e-bevel. Amapayipi angaphandle angaphazamiseki ayatholakala ngama-coupling avamile, ama-bevel akhethekile, noma ama-clearance akhethekile. | |||||||||||||||

Okujwayelekile kanye neBanga

Ukufakwa kwekheyisi kanye nokufakwa kwamapayipi Amabanga Ajwayelekile:

I-API 5CT J55,K55,L80, N80,P110, C90, T95, H40

Iziphetho ze-API 5CT casing kanye nepayipi:

(STC) Ikesi lentambo eliyindilinga elifushane

(LC) Ikesi lentambo ende eyindilinga

(BC) Ibhokisi lentambo ye-Buttress

(XC)Ibhokisi elinomugqa owedlulele

(NU)Ipayipi elingaphazamiseki

(EU) Amapayipi angaphandle avaliwe

(IJ)Ipayipi elihlanganisiwe lamalunga

Ibhokisi kanye nepayipi kufanele kuthunyelwe ngokwezixhumi ezingenhla nezindinganiso ze-API5CT / API Standards.

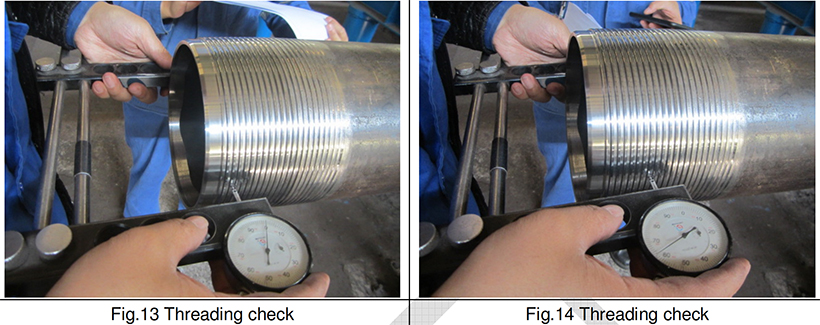

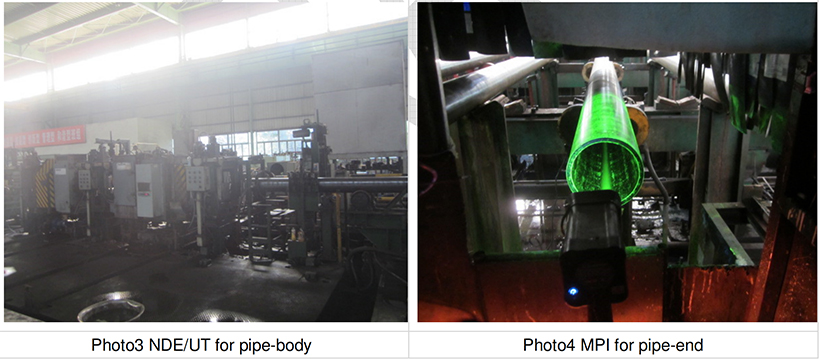

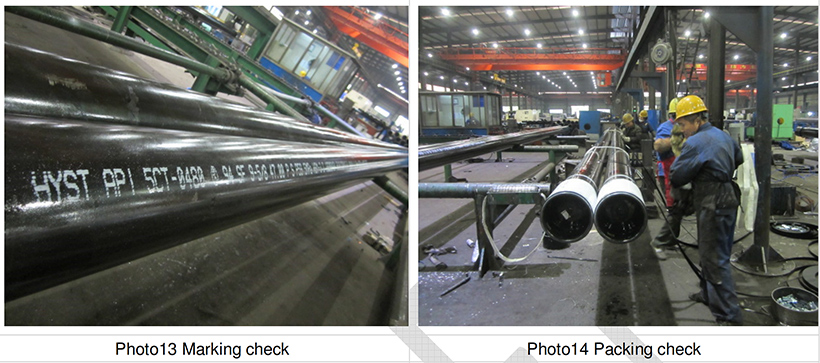

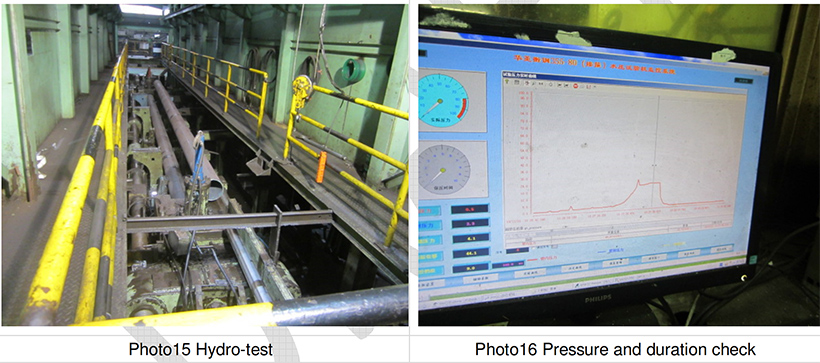

Ikhwalithi yokulawula

Ukuhlolwa Kwezinto Ezingavuthiwe, Ukuhlaziywa Kwamakhemikhali, Ukuhlolwa Kwemishini, Ukuhlolwa Okubonakalayo, Ukuhlolwa Kokucindezeleka, Ukuhlolwa Kobukhulu, Ukuhlolwa Kokugoba, Ukuhlolwa Kokuthamba, Ukuhlolwa Komthelela, Ukuhlolwa Kwe-DWT, Ukuhlolwa Kwe-NDT, Ukuhlolwa Kwamanzi, Ukuhlolwa Kokuqina…..

Ukumaka, Ukupenda ngaphambi kokulethwa.

Ukupakisha Nokuthumela

Indlela yokufaka amapayipi ensimbi ihilela ukuhlanza, ukuqoqa, ukugoqa, ukubopha, ukubopha, ukulebula, ukufaka amaphalethi (uma kudingeka), ukufaka amabhokisi, ukuvala, ukuvala, ukuhambisa, kanye nokukhipha. Izinhlobo ezahlukene zamapayipi ensimbi nezinsimbi ezinezindlela ezahlukene zokupakisha. Le nqubo ephelele iqinisekisa ukuthi amapayipi ensimbi athunyelwa futhi afike lapho eya khona esesimweni esihle kakhulu, elungele ukusetshenziswa kwawo okuhlosiwe.

Ukusetshenziswa Nokusetshenziswa

Amapayipi ensimbi asebenza njengomgogodla wobunjiniyela bezimboni kanye nobezokwakha banamuhla, esekela izinhlelo zokusebenza eziningi ezifaka isandla ekuthuthukisweni kwemiphakathi kanye nomnotho emhlabeni jikelele.

Amapayipi ensimbi kanye nezinto zokufakelwa esizikhiqizele iWomic Steel ezisetshenziswa kabanzi kumapayipi kaphethiloli, igesi, uphethiloli kanye namanzi, amaphrojekthi okwakha amachweba olwandle kanye nokwakha, ukumba, insimbi yesakhiwo, amaphrojekthi okwakha amapulangwe kanye namabhuloho, kanye namapayipi ensimbi anembile okukhiqiza amarola okuhambisa, njll.