Incazelo Yomkhiqizo

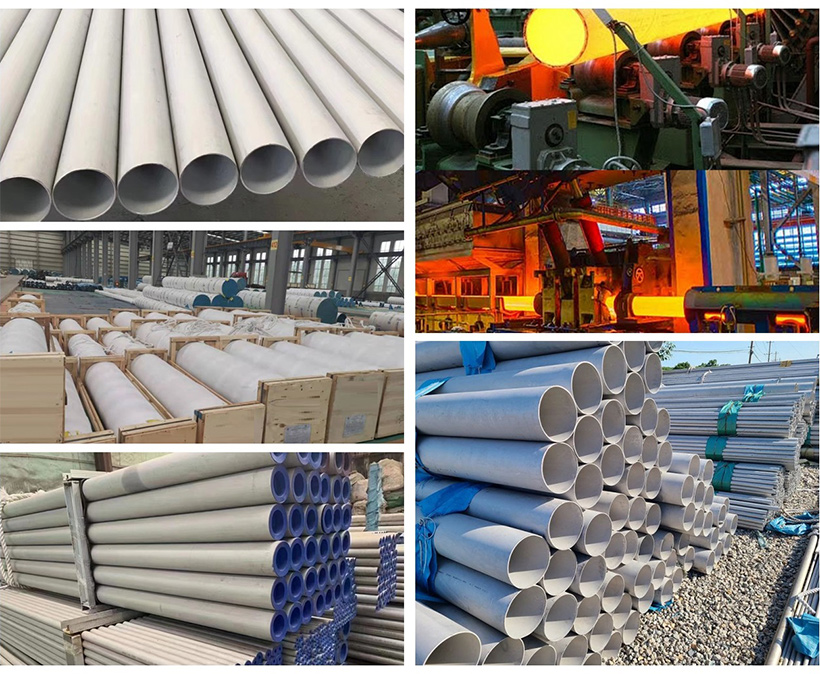

Amapayipi ensimbi angenasici ayingxenye ebalulekile ekusetshenzisweni kwezimboni zesimanje, aziwa ngokuqina kwawo okumangalisayo, ukumelana nokugqwala, kanye nokwakhiwa kwawo okungenasici. Aqukethe i-alloy eyingqayizivele yensimbi, i-chromium, nezinye izinto ezifana ne-nickel ne-molybdenum, la mapayipi abonisa amandla angenakuqhathaniswa kanye nokuphila isikhathi eside.

Inqubo yokukhiqiza engenamthungo ihilela ukukhipha ama-billets ensimbi aqinile ukuze kwakheke amashubhu angenalutho ngaphandle kwanoma yiziphi izihlanganisi ezihlanganisiwe. Le ndlela yokwakha isusa izindawo ezibuthakathaka ezingaba khona futhi ithuthukise ubuqotho besakhiwo, okwenza amapayipi ensimbi engenamthungo athembeke kakhulu ezinhlotsheni ezahlukahlukene.

Izimfanelo Eziyinhloko:

Ukumelana Nokugqwala:Ukufakwa kwe-chromium kudala ungqimba lwe-oxide oluvikelayo, oluvikela amapayipi ekugqwaleni nasekugqwaleni ngisho nasezindaweni ezinzima.

Amabanga Ahlukahlukene:Amapayipi angenasici angenamthungo atholakala ngezinhlobo ezahlukene ezifana no-304, 316, 321, kanye no-347, ngalinye lenzelwe ukusetshenziswa okuthile ngenxa yokwehluka kokwakheka kwamakhemikhali kanye nezakhiwo zemishini.

Izicelo Ezibanzi:Lawa mapayipi asetshenziswa emikhakheni eminingi, okuhlanganisa uwoyela negesi, ukucubungula amakhemikhali, ukudla neziphuzo, imithi, izimoto, kanye nokwakha. Ukuzivumelanisa nezimo nezinto ezahlukene kugcizelela ukuguquguquka kwawo.

Osayizi kanye Nokuqedwa:Amapayipi ensimbi angagqwali angenamthungo afika ngobukhulu obuhlukahlukene, ehlangabezana nezidingo ezahlukahlukene. Amapayipi angaba nokuqedwa okuhlukile kobuso, kusukela ekuqedweni okupholishiwe kuya ekuqedweni komshini, ngokusekelwe ezidingweni zokusetshenziswa.

Ukufakwa Nokugcinwa:Umklamo ongenamthungo wenza kube lula ukufaka kuyilapho ukumelana kwamapayipi nokugqwala kunciphisa izidingo zokugcinwa, okubangela ukusebenza kahle kwezindleko.

Kusukela ekwenzeni kube lula ukuthuthwa kukawoyela negesi kuye ekuvumeleni ukuthuthwa kwamakhemikhali ngokuphepha nokugcina ubumsulwa bemikhiqizo yemithi, amapayipi ensimbi angagqwali angenamthungo adlala indima ebalulekile ekwakheni izimboni emhlabeni jikelele. Ukuhlanganiswa kwawo kwamandla, ukuqina, kanye nokumelana nezici zemvelo kuwenza abe yimpahla ebalulekile kwezobunjiniyela besimanje kanye nengqalasizinda.

Imininingwane

| I-ASTM A312/A312M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H njll.... |

| EN 10216-5: 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 njll... |

| I-DIN 17456: 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 njll... |

| I-JIS G3459: SUS304TB, SUS304LTB, SUS316TB, SUS316LTB njll.. |

| GB/T 14976: 06Cr19Ni10, 022Cr19Ni10, 06Cr17Ni12Mo2 |

| Insimbi engagqwali yase-Austenitic:TP304, TP304L, TP304H, TP310S, TP316, TP316L, TP316H, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H, TP347HFG N08904(904L), S30432, S31254, N08367, S30815... Insimbi engagqwali ephindwe kabili:S31803, S32205, S32750, S32760, S32707, S32906... I-Nickel Alloy:N04400, N06600, N06625, N08800, N08810(800H), N08825... Ukusetshenziswa:Izimboni zokukhiqiza uphethiloli, amakhemikhali, igesi yemvelo, amandla kagesi kanye nemishini yemishini. |

| NB | Usayizi | OD mm | I-SCH40S mm | I-SCH5S mm | I-SCH10S mm | I-SCH10 mm | I-SCH20 mm | I-SCH40 mm | I-SCH60 mm | I-XS/80S mm | I-SCH80 mm | I-SCH100 mm | I-SCH120 mm | I-SCH140 mm | I-SCH160 mm | I-SCHXXS mm |

| 6 | 1/8” | 10.29 | 1.24 | 1.73 | 2.41 | |||||||||||

| 8 | 1/4” | 13.72 | 1.65 | 2.24 | 3.02 | |||||||||||

| 10 | 3/8” | 17.15 | 1.65 | 2.31 | 3.20 | |||||||||||

| 15 | 1/2” | 21.34 | 2.77 | 1.65 | 2.11 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | 3/4” | 26.67 | 2.87 | 1.65 | 2.11 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 1” | 33.40 | 3.38 | 1.65 | 2.77 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | 1 1/4” | 42.16 | 3.56 | 1.65 | 2.77 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | ||||||

| 40 | 1 1/2” | 48.26 | 3.68 | 1.65 | 2.77 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | 2” | 60.33 | 3.91 | 1.65 | 2.77 | 3.91 | 5.54 | 5.54 | 9.74 | 11.07 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | ||||||

| 80 | 3” | 88.90 | 5.49 | 2.11 | 3.05 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | ||||||

| 90 | 3 1/2” | 101.60 | 5.74 | 2.11 | 3.05 | 5.74 | 8.08 | 8.08 | ||||||||

| 100 | 4” | 114.30 | 6.02 | 2.11 | 3.05 | 6.02 | 8.56 | 8.56 | 11.12 | 13.49 | 17.12 | |||||

| 125 | 5” | 141.30 | 6.55 | 2.77 | 3.40 | 6.55 | 9.53 | 9.53 | 12.70 | 15.88 | 19.05 | |||||

| 150 | 6” | 168.27 | 7.11 | 2.77 | 3.40 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8” | 219.08 | 8.18 | 2.77 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 19.26 | 20.62 | 23.01 | 22.23 | |

| 250 | 10” | 273.05 | 9.27 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 | 12.70 | 15.09 | 19.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 300 | 12” | 323.85 | 9.53 | 3.96 | 4.57 | 6.35 | 10.31 | 14.27 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 350 | 14” | 355.60 | 9.53 | 3.96 | 4.78 | 6.35 | 7.92 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16” | 406.40 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 12.70 | 16.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |

| 450 | 18” | 457.20 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20” | 508.00 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |

| 550 | 22” | 558.80 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24” | 609.60 | 9.53 | 5.54 | 6.35 | 6.35 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26” | 660.40 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 700 | 28” | 711.20 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 750 | 30” | 762.00 | 9.53 | 6.35 | 7.92 | 7.92 | 12.70 | 12.70 | ||||||||

| 800 | 32” | 812.80 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 850 | 34” | 863.60 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 900 | 36” | 914.40 | 9.53 | 7.92 | 12.70 | 19.05 | 12.70 |

Okujwayelekile kanye neBanga

| Okujwayelekile | Amabanga Ensimbi |

| I-ASTM A312/A312M: Amapayipi Ensimbi Engagqwali E-Austenitic Angenamthungo, Ashiselwe, Futhi Abandayo Kakhulu | 304, 304L, 310S, 310H, 316, 316L, 321, 321H njll... |

| I-ASTM A213: Ibhoyila yensimbi ye-ferritic ne-austenitic engenamthungo, i-superheater, kanye namashubhu okushintshanisa ukushisa | TP304, TP304L, TP316, TP316L, TP321.TP347 njll... |

| I-ASTM A269: Amapayipi ensimbi engagqwali e-austenitic angenamthungo futhi ahlanganisiwe ukuze asebenze ngokujwayelekile | TP304, TP304L, TP316, TP316L, TP321.TP347 njll... |

| I-ASTM A789: Amapayipi ensimbi engagqwali e-ferritic/austenitic angenamthungo futhi ashiselwe ukuze asetshenziswe ngokujwayelekile | I-S31803 (Insimbi engagqwali ye-Duplex) I-S32205 (Insimbi engagqwali ye-Duplex) |

| I-ASTM A790: Ipayipi lensimbi engagqwali le-ferritic/austenitic elingenamthungo nelihlanganisiwe lenkonzo yokugqwala evamile, isevisi yokushisa okuphezulu, kanye namapayipi ensimbi engagqwali amabili. | I-S31803 (Insimbi engagqwali ye-Duplex) I-S32205 (Insimbi engagqwali ye-Duplex) |

| I-EN 10216-5: Izinga laseYurophu lamapayipi ensimbi angenamthungo ngezinjongo zokucindezela | 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 njll... |

| I-DIN 17456: Izinga lesiJalimane leThubhu Yensimbi Engagqwali Eyisiyingi Engenamthungo | 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 njll... |

| I-JIS G3459: Izinga Lezimboni LaseJapan Lamapayipi Ensimbi Engagqwali Okumelana Nokugqwala | I-SUS304TB, i-SUS304LTB, i-SUS316TB, i-SUS316LTB njll. |

| I-GB/T 14976: Izinga Likazwelonke LaseShayina Lamapayipi Ensimbi Engagqwali Angenamthungo Okuthutha Okuketshezi | 06Cr19Ni10, 022Cr19Ni10, 06Cr17Ni12Mo2 |

| Insimbi engagqwali ye-Austenitic:TP304, TP304L, TP304H, TP310S, TP316, TP316L, TP316H, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H, TP347HFG N08904(904L), S30432, S31254, N08367, S30815... Insimbi engagqwali ephindwe kabili:S31803, S32205, S32750, S32760, S32707, S32906... I-Nickel Alloy:N04400, N06600, N06625, N08800, N08810(800H), N08825... Ukusetshenziswa: I-Petroleum, Amakhemikhali, Igesi Yemvelo, Amandla Kagesi kanye nezimboni zokukhiqiza imishini yemishini. | |

Inqubo Yokukhiqiza

Inqubo Yokugoqa Okushisayo (Ipayipi Lensimbi Engenamthungo Ekhishwe):

I-billet yeshubhu eyindilinga→ukushisa→ukubhoboza→ukugoqa okunezimbobo ezintathu, ukugoqa okuqhubekayo noma ukukhishwa kweshubhu→ukususwa kweshubhu→usayizi (noma ukunciphisa ububanzi)→ukupholisa→ukuqondisa→ukuhlolwa kwe-hydraulic (Noma ukutholwa kwamaphutha)→uphawu→isitoreji

Inqubo Yeshubhu Yensimbi Engenamthungo Edonswe Ngobandayo (Egoqwe):

I-billet yeshubhu eliyindilinga→ukushisa→ukubhoboza→isihloko→ukumboza→ukukhahlela→ukugcoba (ukucwebezela ngethusi)→ukudweba okubandayo okudlula izikhathi eziningi (ukugoqa okubandayo)→i-billet→ukwelashwa kokushisa→ukuqondisa→ukuhlolwa kwe-Hydraulic (ukutholwa kwamaphutha)→Ukumaka→Isitoreji.

Ikhwalithi yokulawula

Ukuhlolwa Kwezinto Ezingavuthiwe, Ukuhlaziywa Kwamakhemikhali, Ukuhlolwa Kwemishini, Ukuhlolwa Okubonakalayo, Ukuhlolwa Kobukhulu, Ukuhlolwa Kokugoba, Ukuhlolwa Komthelela, Ukuhlolwa Kokugqwala Okuphakathi Kwezinhlayiya, Ukuhlolwa Kokugqama Nokusonta (UT, MT, PT), Ukuhlolwa Kokuqina, Ukuhlolwa Kokucindezela, Ukuhlolwa Kokuqukethwe Kwe-Ferrite, Ukuhlolwa Kwe-Metallography, Ukuhlolwa Kokugqwala, Ukuhlolwa Kwamanje Kwe-Eddy, Ukuhlolwa Kokufafaza Usawoti, Ukuhlolwa Kokumelana Nokugqwala, Ukuhlolwa Kokudlidliza, Ukuhlolwa Kokugqwala Kwe-Pitting, Ukuhlolwa Kokupenda Nokumboza, Ukubuyekezwa Kwamadokhumenti…..

Ukusetshenziswa Nokusetshenziswa

Amapayipi angenasici angenasici ayizinto ezibalulekile ezisetshenziswa kabanzi emikhakheni eyahlukahlukene ngenxa yokumelana kwawo nokugqwala okumangalisayo, amandla aphezulu, kanye nekhono lokubekezelela amazinga okushisa aphezulu. Nazi ezinye zezindlela eziyinhloko zokusebenzisa amapayipi angenasici angenasici:

Imboni Kawoyela Negesi:Amapayipi angenasici angenamthungo avame ukusetshenziswa ekuhloleni uwoyela negesi, ekuthuthweni nasekucubungulweni. Asetshenziselwa izimbobo zemithombo, amapayipi, kanye nemishini yokucubungula ngenxa yokumelana kwawo nokugqwala koketshezi namagesi.

Imboni Yamakhemikhali:Ekucutshungulweni nasekukhiqizweni kwamakhemikhali, amapayipi angenasici angenamthungo asetshenziswa ukudlulisa ama-asidi, izisekelo, izinyibilikisi, nezinye izinto ezibolayo. Anegalelo ekuphepheni nasekuthembekeni kwezinhlelo zamapayipi.

Imboni Yamandla:Amapayipi angenasici angenamthungo adlala indima ebalulekile ekukhiqizweni kwamandla, okuhlanganisa amandla enuzi, amaseli kaphethiloli, kanye namaphrojekthi amandla avuselelekayo, amapayipi nemishini.

Imboni Yokudla Neziphuzo:Ngenxa yokuhlanzeka kwawo kanye nokumelana nokugqwala, amapayipi angenasici angenamthungo asetshenziswa kabanzi ekucubungulweni kokudla nasekukhiqizweni kweziphuzo, okuhlanganisa nokuhanjiswa koketshezi, amagesi, nezinto zokudla.

Imboni Yezemithi:Ekukhiqizeni imithi kanye nokukhiqizwa kwemithi, amapayipi angenasici angenamthungo asetshenziswa ukuthutha nokuphatha izithako zemithi, ukuhlangabezana nezindinganiso zokuhlanzeka kanye nekhwalithi.

Ukwakhiwa kwemikhumbi:Amapayipi angenasici angenamthungo asetshenziswa ekwakheni imikhumbi yokwakha izakhiwo zemikhumbi, izinhlelo zamapayipi, kanye nemishini yokwelapha amanzi olwandle, ngenxa yokumelana kwawo nokugqwala kwemvelo yasolwandle.

Izinto Zokwakha Nezokwakha:Amapayipi angenasici angenamthungo asetshenziswa ekwakheni asetshenziswa kumapayipi okuhambisa amanzi, izinhlelo ze-HVAC, kanye nezingxenye zesakhiwo zokuhlobisa.

Imboni Yezimoto:Emkhakheni wezimoto, amapayipi angenasici angenamthungo asetshenziswa ezinhlelweni zokukhipha ugesi ngenxa yokumelana kwawo nokushisa okuphezulu kanye nokumelana nokugqwala.

Ukumbiwa Kwezimayini Nokusetshenzwa Kwensimbi:Emasimini ezimayini kanye nezinsimbi, amapayipi angenasici angenamthungo asetshenziswa ukuthutha izinsimbi eziyigugu, ama-slurries, kanye nezixazululo zamakhemikhali.

Ngamafuphi, amapayipi angenamthungo ensimbi engagqwali ayasebenziseka futhi anikeza ukusebenza okuphezulu, okwenza afaneleke emikhakheni eyahlukahlukene. Adlala indima ebalulekile ekuqinisekiseni ukuphepha kwenqubo, ukuthuthukisa ukuthembeka kwemishini, kanye nokwandisa isikhathi senkonzo. Izinhlelo ezahlukene zidinga amapayipi angenamthungo ensimbi engagqwali anezincazelo ezithile nezinto zokwakha ukuze ahlangabezane nezidingo zawo ezihlukile.

Ukupakisha Nokuthumela

Amapayipi ensimbi engagqwali ayapakishwa futhi athunyelwe ngokucophelela okukhulu ukuqinisekisa ukuvikeleka kwawo ngesikhathi sokuthutha. Nansi incazelo yenqubo yokupakisha nokuthumela:

Ukupakisha:

● Ukuvikela: Ngaphambi kokupakisha, amapayipi ensimbi engagqwali avame ukumbozwa ngesendlalelo samafutha noma ifilimu yokuvikela ukuvimbela ukugqwala nomonakalo womphezulu.

● Ukubopha: Amapayipi anobukhulu obufanayo kanye nemininingwane efanayo ahlanganiswa ngokucophelela. Aqiniswa kusetshenziswa izintambo, izintambo, noma amabhande epulasitiki ukuvimbela ukunyakaza ngaphakathi kwenqwaba.

● Izivalo Zokugcina: Izivalo zokugcina zepulasitiki noma zensimbi zifakwa kuzo zombili izinhlangothi zamapayipi ukuze kunikezwe isivikelo esengeziwe eziphethweni zamapayipi kanye nezintambo.

● Ukugoqa Nokusonga: Izinto zokufaka ama-padding ezifana ne-foam, i-bubble wrap, noma ikhadibhodi eligoqiwe zisetshenziselwa ukuhlinzeka ngokugoqa nokuvimbela umonakalo ngesikhathi sokuthuthwa.

● Amabhokisi noma Amabhokisi Okhuni: Kwezinye izimo, amapayipi angase apakishwe emabhokisini noma emabhokisini okhuni ukuze ahlinzeke ngesivikelo esengeziwe emandleni angaphandle nasekuphathweni.

Ukuthunyelwa:

● Indlela Yokuhamba: Amapayipi ensimbi engagqwali avame ukuthunyelwa kusetshenziswa izindlela ezahlukene zokuhamba njengemaloli, imikhumbi, noma imithwalo yendiza, kuye ngokuthi uyaphi kanye nokuphuthuma.

● Ukufakwa kweziqukathi: Amapayipi angafakwa ezitsheni zokuthumela impahla ukuqinisekisa ukuthi izinto zokuhamba ziphephile futhi zihlelekile. Lokhu kunikeza nokuvikelwa ezimweni zezulu kanye nokungcola kwangaphandle.

● Ukulebula kanye Nemibhalo: Iphakheji ngayinye ilebula ngolwazi olubalulekile, okuhlanganisa imininingwane, ubuningi, imiyalelo yokuphatha, kanye nemininingwane yendawo oya kuyo. Amadokhumenti okuthumela alungiselelwa ukusulwa kwempahla kanye nokulandelwa kwempahla.

● Ukuthobela Imithetho Yentela: Ngokuthunyelwa kwamanye amazwe, yonke imibhalo yentela edingekayo ilungiselelwe ukuqinisekisa ukuthi izimpahla zifika kalula endaweni oya kuyo.

● Ukubopha Okuqinile: Ngaphakathi kwemoto yokuthutha noma isitsha, amapayipi aboshwe kahle ukuze kuvinjelwe ukunyakaza nokunciphisa ingozi yomonakalo ngesikhathi sokuthutha.

● Ukulandelela Nokuqapha: Izinhlelo zokulandelela ezithuthukisiwe zingasetshenziswa ukuqapha indawo kanye nesimo sokuthunyelwa ngesikhathi sangempela.

● Umshwalense: Kuye ngenani lempahla, umshwalense wokuthumela ungatholakala ukuze umboze ukulahlekelwa noma umonakalo ongaba khona ngesikhathi sokuthutha.

Ngamafuphi, amapayipi ensimbi engagqwali esiwakhiqizile azopakishwa ngezinyathelo zokuzivikela futhi athunyelwe kusetshenziswa izindlela zokuthutha ezinokwethenjelwa ukuqinisekisa ukuthi afika lapho aya khona esesimweni esihle kakhulu. Izinqubo ezifanele zokupakisha nokuthumela zinegalelo ekuqineni nasekhwalithini yamapayipi alethiwe.