Ukubuka Konke Komkhiqizo

I-Womic Steel ingumkhiqizi ohamba phambili we-I-EN 10305Amashubhu ensimbi angenamthungo aqinisekisiwe, aklanyelwe ukunemba, amandla, kanye nokuqina kuzo zonke izinhlelo zokusebenza zezimboni. Amashubhu ethu ensimbi angenamthungo aklanywe ukuze ahlangabezane nezindinganiso zomhlaba wonke eziqinile, ahlinzeka ngokusebenza okuhle kakhulu kwezinhlelo zokuthutha zemishini, zesakhiwo, kanye nezoketshezi. Kusukela kubunjiniyela bezimoto kuya kumasilinda e-hydraulic, i-Womic Steel iqinisekisa ukuthi ishubhu ngalinye lenzelwe ubuhle, okuqinisekisa ikhwalithi nokuthembeka okumangalisayo.

OkwethuAmashubhu ensimbi angenamthungo e-EN 10305zilungele izinhlelo zokusebenza ezinamandla aphezulu ezidinga ubukhulu obuqondile, izakhiwo ezinhle kakhulu zemishini, kanye nokumelana okuqinile nokuguguleka nokugqwala. Lawa mashubhu asetshenziswa ezimbonini eziningi, kufaka phakathi izimoto, imishini, ukuthuthwa koketshezi, kanye nobunjiniyela bemishini, okunikeza izixazululo ezithembekile zezinhlelo zokusebenza zobunjiniyela obunembile.

I-EN 10305 Uhla Lokukhiqiza Amashubhu Ensimbi Angenamthungo

Abakhiqizi beWomic SteelAmashubhu ensimbi angenamthungo e-EN 10305ngobukhulu nobukhulu obuhlukahlukene, okuqinisekisa ukuguquguquka kwezinhlelo zokusebenza ezahlukahlukene. Uhla olujwayelekile lokukhiqiza luhlanganisa:

- Ububanzi Bangaphandle (OD)Ububanzi: 6 mm kuya ku-406 mm

- Ubukhulu Bodonga (WT): 1 mm kuya ku-18 mm

- Ubude: Ubude obungokwezifiso, ngokuvamile busukela kumamitha ayi-6 kuya kwangu-12, buyatholakala uma ikhasimende licela.

Lawa mashubhu angakhiqizwa ngezidingo ezithile zamadayamitha, ubude, kanye nobukhulu bodonga ngokwezifiso ngokusekelwe ezicacisweni zamakhasimende kanye nezidingo zephrojekthi.

Ukubekezelelana kwamapayipi ensimbi angenamthungo e-EN 10305

I-Womic Steel'sAmashubhu ensimbi angenamthungo e-EN 10305zenzelwe ukugxila ekuqondeni kahle. Siqinisekisa ukubekezelelana okulandelayo kwemikhiqizo yethu

| Ipharamitha | Ukubekezelelana |

| Ububanzi Bangaphandle (OD) | ± 0.01 mm |

| Ubukhulu Bodonga (WT) | ± 0.1 mm |

| Ukuvaleka (Ukuma) | 0.1 mm |

| Ubude | ± 5 mm |

| Ukuqonda | Umkhawulo ongu-0.5 mm ngemitha |

| Ukuqedwa Komphezulu | Ngokwencazelo yekhasimende (ngokuvamile: Uwoyela Olwa Nokugqwala, I-Hard Chrome Plating, I-Nickel Chromium Plating, noma ezinye izembozo) |

| Ubungako Beziphetho | ± 1° |

Izimo Zokulethwa Kwamashubhu Ensimbi Angenamthungo e-EN 10305

Amapayipi akhiqizwa kusetshenziswaumdwebo obandayonomaukugoqa okubandayoizinqubo futhi zihlinzekwa ezimweni ezahlukene zokulethwa ngokusekelwe ezidingweni ezithile zamakhasimende. Lokhu kufaka phakathi:

Ithebula 1 — Izimo zokulethwa

| Ukuqokwa | Uphawua | Incazelo |

| Kudonswe ngokubandayo / kuqinile | +C | Akukho ukwelashwa kokushisa kokugcina ngemva kokudonsa kokugcina okubandayo. |

| Kudonswe ngokubandayo / kuthambile | +LC | Ukwelashwa kokushisa kokugcina kulandelwa umdwebo ofanele ukudlula (ukunciphisa indawo okulinganiselwe). |

| Kudonswa ubanda futhi kuncishiswe ukucindezeleka | +SR | Ngemva kokudweba kokugcina okubandayo, amapayipi ancishiswa ukucindezeleka esimweni esilawulwayo. |

| I-anneal ethambile | +A | Ngemva kokudweba kokugcina okubandayo, amapayipi ayafakwa endaweni ethambile elawulwayo. |

| Okujwayelekile | +N | Ngemva kokudweba kokugcina okubandayo, amapayipi alungiswa ngendlela evamile umoya olawulwayo. |

| a: Ngokuvumelana ne-EN10027–1. | ||

I-EN 10305 Amashubhu Ensimbi Angenamthungo Ukwakheka Kwamakhemikhali

II-EN 10305Amashubhu akhiqizwa ngamamaki ensimbi asezingeni eliphezulu. Ngezansi umbono jikelele wamamaki ezinto ezijwayelekile kanye nokwakheka kwawo kwamakhemikhali:

Ithebula 2 — Ukwakheka kwamakhemikhali (ukuhlaziywa kwe-cast)

| Ibanga lensimbi | % ngobuningi | ||||||

| Igama lensimbi | Insimbi | C | Si | Mn | P | Sa | Alisambab |

| inombolo | |||||||

| E215 | 1.0212 | 0,10 | 0,05 | 0,70 | 0,025 | 0,025 | 0,025 |

| E235 | 1.0308 | 0,17 | 0,35 | 1,20 | 0,025 | 0,025 | 0,015 |

| E355 | 1.0580 | 0,22 | 0,55 | 1,60 | 0,025 | 0,025 | 0,020 |

| Izinto ezingacashunwanga kuleli thebula (kodwa bheka umbhalo waphansib) ngeke kwengezwe ngamabomu ensimbini ngaphandle kwesivumelwano somthengi, ngaphandle kwezinto ezingangezwa ngenhloso yokususa i-oxidation kanye/noma ukubopha i-nitrogen. Zonke izinyathelo ezifanele kufanele zithathwe ukuvimbela ukwengezwa kwezinto ezingafuneki ezivela ezingcezwini ezilahliwe noma ezinye izinto ezisetshenziswa enkambisweni yokwenza insimbi. | |||||||

| Bheka inketho 2. b Lesi sidingo asisebenzi uma nje insimbi iqukethe inani elanele lezinye izinto ezibopha i-nitrogen, njenge-Ti, i-Nb noma i-V. Uma kungeziwe, okuqukethwe kwalezi zinto kufanele kubikwe kumbhalo wokuhlola. Uma usebenzisa i-titanium, umenzi kufanele aqinisekise ukuthi (Al + Ti/2) ≥ 0,020. | |||||||

Inketho 2: Kumagremu ensimbi i-E235 kanye ne-E355, okuqukethwe kwe-sulphur okulawulwayo okungu-0,015% kuya ku-0,040% kucacisiwe ukusekela ukusebenza kahle komshini. Kuzotholakala ngokuphinda kufakwe i-sulphur ensimbi ngemva kokukhipha i-sulphur eningi kakhulu noma ngokusebenzisa inqubo ye-oxygen ephansi.

Inketho 3: Ukwakheka kwamakhemikhali kwesigaba sensimbi esichaziwe kufanele kube ngendlela yokuthi kufanelekele ukugaya ngokushisa (bheka isib. EN ISO 1461 noma EN ISO 14713-2 ukuze uthole isiqondiso).

Ithebula 3 kanye neThebula A.2 zichaza ukuphambuka okuvunyelwe kokuhlaziywa komkhiqizo kusuka emikhawulweni ecacisiwe ekuhlaziyweni kwe-cast okunikezwe kuThebula 2 kanye neThebula A.1

Ithebula 3 — Ukuphambuka okuvunyelwe kokuhlaziywa komkhiqizo kusuka emikhawulweni ecacisiwe ekuhlaziyweni kwe-cast okunikezwe kuThebula 2

| Isici | Inani elilinganiselwe labalingisi | Ukuphambuka okuvunyelwe kokuhlaziywa komkhiqizo |

| C | ≤0,22 | +0,02 |

| Si | ≤0,55 | +0,05 |

| Mn | ≤1,60 | +0,10 |

| P | ≤0,025 | +0,005 |

| S | ≤0,040 | ±0,005 |

| Al | ≥0,015 | -0,005 |

Izakhiwo Zemishini Zezingqimba Zensimbi Ezingenamthungo ze-EN 10305

Izakhiwo zemishini zeI-EN 10305Amashubhu ensimbi angenamthungo, alinganiswa ngokushisa kwegumbi, alandelayo. Lawa manani ancike ebangeni lensimbi kanye nesimo sokulethwa:

Ithebula 4 — Izakhiwo zemishini ekushiseni kwegumbi

| Ibanga lensimbi | Amanani aphansi kakhulu esimo sokulethwaa | ||||||||||||

| +Cb | +LCb | +SR | +Ac | +N | |||||||||

| Insimbi | Insimbi | Rm | A | Rm | A | Rm | ReH | A | Rm | A | Rm | ReHd | A |

| igama | inombolo | I-MPa | % | I-MPa | % | I-MPa | I-MPa | % | I-MPa | % | I-MPa | I-MPa | % |

| E215 | 1.0212 | 430 | 8 | 380 | 12 | 380 | 280 | 16 | 280 | 30 | 290 kuya ku-430 | 215 | 30 |

| E235 | 1.0308 | 480 | 6 | 420 | 10 | 420 | 350 | 16 | 315 | 25 | 340 kuya ku-480 | 235 | 25 |

| E355 | 1.058 | 640 | 4 | 580 | 7 | 580 | 450e | 10 | 450 | 22 | 490 kuya ku-630 | 355 | 22 |

| u-Rm: amandla okudonsa; ReH: amandla okukhiqiza okuphezulu (kodwa bheka u-11.1); A: ukunwebeka ngemva kokuphuka. Ukuze uthole izimpawu zesimo sokulethwa bheka iThebula 1 | |||||||||||||

| b Kuye ngezinga lomsebenzi obandayo ekuqedeni, amandla okukhiqiza angase afane namandla okudonsa. Ngezinjongo zokubala, kunconywa ubudlelwano obulandelayo: —ngokwesimo sokulethwa +C: ReH≥0,8 Rm; —ngokwesimo sokulethwa +LC: ReH≥0,7 Rm. | |||||||||||||

| c Ngezinhloso zokubala, kunconywa ubudlelwano obulandelayo: ReH≥0,5 Rm. | |||||||||||||

| d Kwamashubhu anobubanzi bangaphandle obuyi-≤30mm kanye nobukhulu bodonga obuyi-≤3mm u-ReHamanani aphansi angu-10MPa kunamanani anikezwe kuleli thebula. | |||||||||||||

| e Kwamashubhu anobubanzi bangaphandle >160mm: ReH≥420MPa. | |||||||||||||

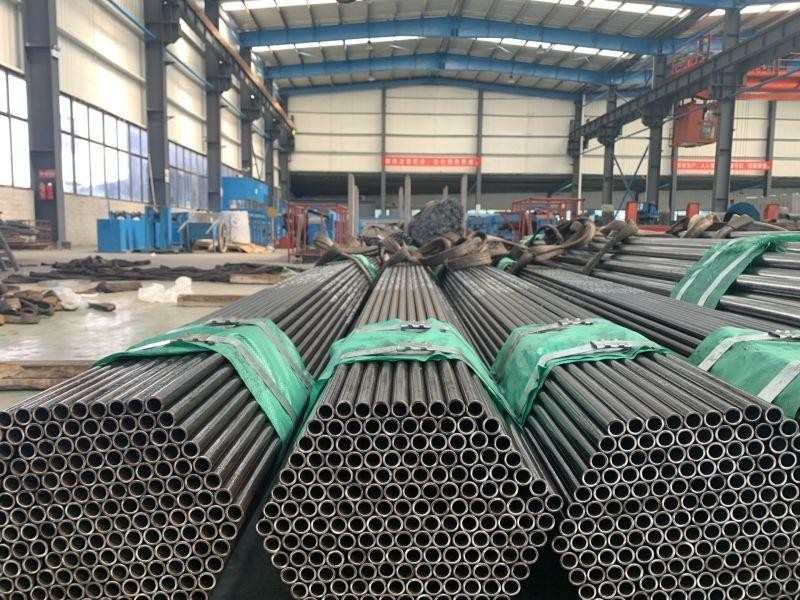

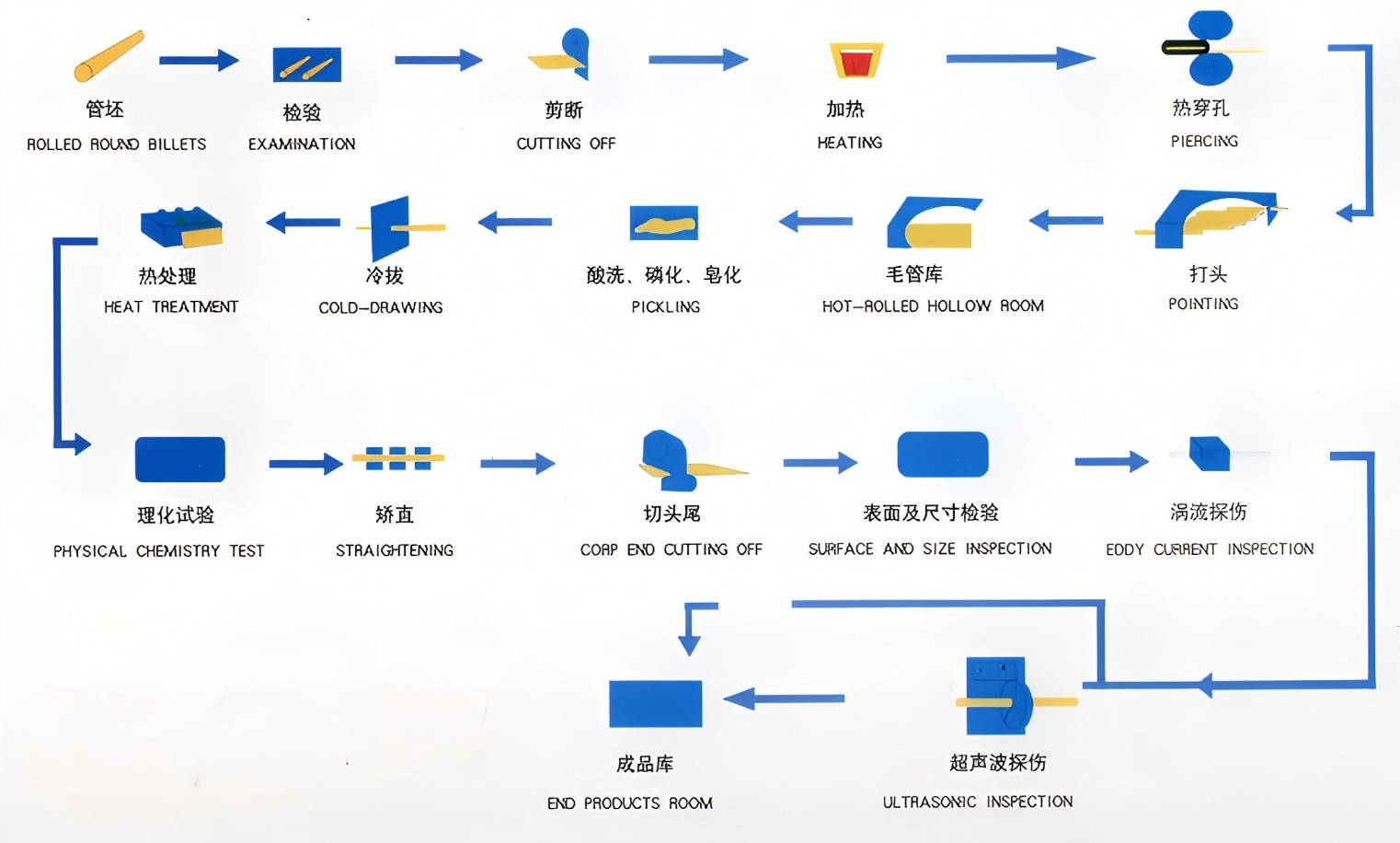

Inqubo Yokukhiqiza Amashubhu Ensimbi Angenamthungo ye-EN 10305

I-Womic Steel isebenzisa amasu okukhiqiza athuthukile ukukhiqizaAmashubhu ensimbi angenamthungo e-EN 10305, ukuqinisekisa imikhiqizo esezingeni eliphezulu, eklanywe ngokunemba. Inqubo ihilela izigaba ezilandelayo ezibalulekile:

- Ukukhethwa Nokuhlolwa Kwe-Billet:

Inqubo yokukhiqiza iqala ngama-billet ensimbi asezingeni eliphezulu, ahlolwe kahle ukuqinisekisa ukuvumelana nokuhambisana nemininingwane yezinto ezibonakalayo. - Ukushisa Nokubhoboza:

Ama-billet ashiswa kuze kufike ezingeni lokushisa elifanele bese ebhobozwa ukuze akhe ipayipi elingenalutho, okuwalungiselela ukwakheka okwengeziwe. - Ukugoqa Okushisayo:

Ama-billet angenalutho aqhutshwa ngokushisa ukuze akhe ithubhu, alungise ubukhulu bomkhiqizo wokugcina. - Umdwebo Obandayo:

Amapayipi aguqiwe ngokushisa adonswa ngama-dies ngaphansi kwezimo ezilawulwayo ukuze kufezwe ububanzi obuqondile kanye nobukhulu bodonga. - Ukukhahlela:

Ngemva kokudweba okubandayo, amashubhu ayahlungwa ukuze kususwe noma yisiphi isikali sobuso noma izendlalelo ze-oxide, okuqinisekisa ukuthi ubuso buhlanzekile futhi bubushelelezi. - Ukwelashwa Kokushisa:

Amapayipi afakwa ezinqubweni zokwelashwa ngokushisa njengokufakwa kwe-annealing, okuthuthukisa izakhiwo zawo zemishini futhi kuqinisekiswe ukufana. - Ukuqondisa Nokusika:

Amapayipi ayaqondiswa futhi asikwe ngobude obudingekayo, kugcinwa ukufana nokunemba. - Ukuhlolwa Nokuhlolwa:

Ukuhlolwa okuqinile, okuhlanganisa ukuhlolwa kobukhulu, ukuhlolwa kwemishini, kanye nokuhlolwa okungabhubhisi (NDT), kwenziwa ukuqinisekisa amazinga aphezulu kakhulu.

Ukuhlola Nokuhlola

I-Womic Steel iqinisekisa amazinga aphezulu okuqinisekiswa kwekhwalithi kanye nokulandelelwa ngezinqubo zokuhlola eziphelele zeAmashubhu ensimbi angenamthungo e-EN 10305Lokhu kufaka phakathi:

- Ukuhlolwa Kobukhulu:

Ukulinganiswa kobubanzi bangaphandle, ukujiya kodonga, ubude, ukujiya, kanye nokuqondile. - Ukuhlolwa Kwemishini:

Kufaka phakathi ukuhlolwa kokuthambekela, ukuhlolwa kokushayisana, kanye nokuhlolwa kobulukhuni ukuqinisekisa amandla adingekayo kanye nokuguquguquka. - Ukuhlolwa Okungonakalisi (NDT):

Ukuhlolwa kwamanje kwe-Eddy ukuthola amaphutha angaphakathi, ukuhlolwa kwe-ultrasonic (UT) kobukhulu bodonga kanye nokuqina kwesakhiwo. - Ukuhlaziywa Kwamakhemikhali:

Ukwakheka kwezinto kuqinisekiswa kusetshenziswa izindlela ze-spectrographic ukuqinisekisa ukuthi izinto zihlangabezana nezimfuneko ezidingekayo. - Ukuhlolwa Kwamanzi:

Ipayipi lihlolwa ingcindezi yangaphakathi ukuqinisekisa ukuthi lingakwazi ukumelana nengcindezi yokusebenza ngaphandle kokwehluleka.

Ukulawulwa Kwelebhu Nokwekhwalithi

I-Womic Steel isebenzisa ilabhorethri yesimanje ehlonyiswe ngemishini yokuhlola ethuthukisiwe ukuze yenze ukuhlolwa kwekhwalithi okujulile. Ithimba lethu lobuchwepheshe lenza ukuhlolwa okuvamile kuzo zonke izigabaAmashubhu ensimbi angenamthungo e-EN 10305ukuqinisekisa ukuhambisana nezindinganiso eziqinile zomhlaba wonke. Siphinde sibambisane nezinhlangano zokuhlola zezinkampani zangaphandle ukuze sinikeze ukuqinisekiswa okuzimele kwekhwalithi yamapayipi.

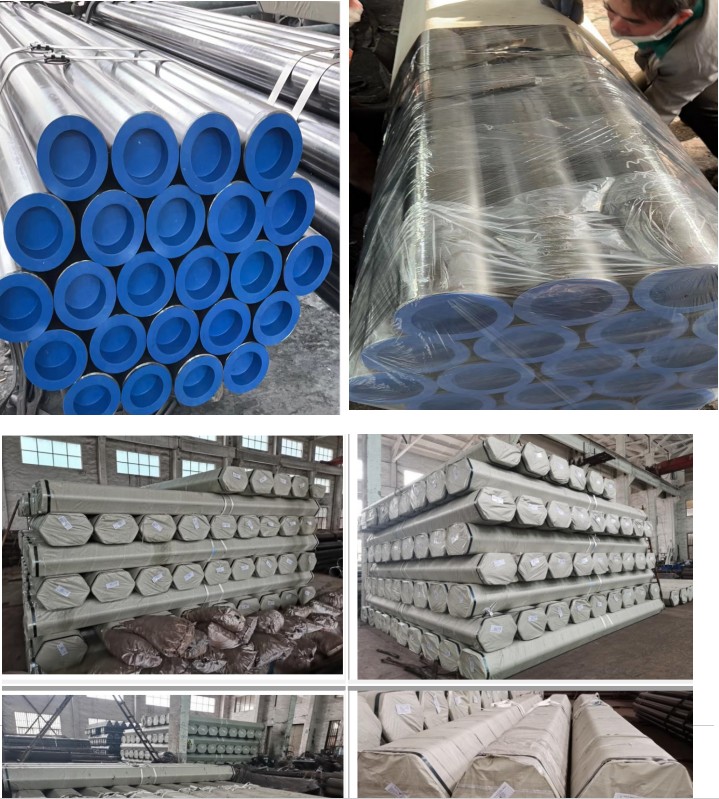

Ukupakisha

IAmashubhu ensimbi angenamthungo e-EN 10305zipakishwa ngokucophelela ukuqinisekisa ukuthi zithuthwa futhi zilethwa ngokuphephile. Ukupakisha kuhlanganisa:

- Isimbozo Esivikelayo:

Ithubhu ngalinye limbozwe ngesendlalelo sokuvikela ukugqwala ukuvimbela ukugqwala kanye nokubola ngesikhathi sokuthuthwa nokugcinwa. - Ama-End Caps:

Izivalo zokugcina zepulasitiki noma zensimbi zifakwa kuzo zombili iziphetho zamapayipi ukuvimbela ukungcola, umswakama, noma umonakalo ongokwenyama. - Ukuhlanganisa:

Amapayipi ahlanganiswa ndawonye ngokuphephile ngamabhande ensimbi noma amabhande epulasitiki ukuze kugcinwe ukuqina nokuvimbela ukunyakaza ngesikhathi sokuthuthwa. - Ukugoqa Okuncane:

Izinqwaba zigoqwa ngefilimu yokunciphisa ukuze kuvikelwe amapayipi othulini, ukungcola, nezinye izinto ezingokwemvelo. - Ukuhlonza Nokulebula:

Iphakheji ngayinye ilebula ngemininingwane yomkhiqizo, okuhlanganisa ibanga lensimbi, ubukhulu, inombolo yebhetshi, ubuningi, kanye nanoma yimiphi imiyalelo ekhethekile yokuphatha.

Ezokuthutha

I-Womic Steel iqinisekisa ukulethwa okufika ngesikhathi nokuthembekile emhlabeni jikelele kwe-Amashubhu ensimbi angenamthungo e-EN 10305ngezindlela zokuthutha ezilandelayo:

Impahla Yasolwandle:

Uma kuthunyelwa kwamanye amazwe, amashubhu afakwa ezitsheni noma ezinqolobaneni ezisicaba bese ethunyelwa kunoma iyiphi indawo emhlabeni jikelele.

Isitimela kanye Nezokuthutha Emgwaqweni:

Uma kuthunyelwa izinto zasekhaya nezesifunda, amashubhu alayishwa ngokuphephile emalorini noma ezitsheni ezisicaba bese ethuthwa ngomgwaqo noma ngesitimela.

Ukulawulwa Kwesimo Sezulu:

Uma kudingeka, singahlela ukuthuthwa okulawulwa yisimo sezulu ukuze kuvikelwe amapayipi ezimweni ezimbi kakhulu zemvelo.

Amadokhumenti kanye Nomshwalense:

Kunikezwa amadokhumenti aphelele okukhishwa kwempahla, ukuthunyelwa, kanye nokulandelela, futhi umshuwalense ungahlelwa wokuthunyelwa kwamanye amazwe ukuze kuvikelwe ekulimaleni noma ekulahlekelweni okungenzeka.

Izinzuzo Zokukhetha Insimbi Yabesifazane

Ukukhiqiza Ngokucophelela:

Silawula ngokuqinile zonke izinqubo zokukhiqiza ukuze sihlangabezane nokubekezelelana okulinganayo.

Ukwenza ngokwezifiso:

Izinketho eziguquguqukayo zobude bamashubhu, ukwelashwa kwendawo, kanye nokupakishwa ngokusekelwe ezimisweni zamakhasimende.

Ukuhlolwa Okuphelele:

Ukuhlolwa okuqinile kuqinisekisa ukuthi ithubhu ngalinye lihlangabezana nezindinganiso ezidingekayo zemishini, zamakhemikhali, kanye nezilinganiso.

Ukulethwa Komhlaba Wonke:

Ukulethwa okuthembekile nokufika ngesikhathi, noma ngabe iphrojekthi yakho ikuphi.

Ithimba Elinolwazi:

Onjiniyela abanekhono kanye nochwepheshe baqinisekisa ikhwalithi ephezulu yokukhiqiza kanye nezindinganiso zesevisi yamakhasimende.

Isiphetho

I-Womic Steel'sAmapayipi Ensimbi Angenamthungo e-EN 10305zenzelwe ukuletha amandla aphezulu, ukuthembeka, kanye nokunemba kwezinhlelo zokusebenza eziningi ezidinga amandla. Ngokuzibophezela kwethu ekhwalithini, ekukhiqizeni okuthuthukisiwe, kanye nokwaneliseka kwamakhasimende, singabalingani abathembekile bezixazululo zamashubhu angenamthungo emhlabeni jikelele.

Khetha i-Womic Steel yakhoAmapayipi Ensimbi Angenamthungo e-EN 10305futhi uhlangabezane nemikhiqizo esebenza kahle kakhulu esekelwa ubuchwepheshe obungenakuqhathaniswa.

Ukuze uthole imininingwane eyengeziwe, sicela usithinte ngqo:

Iwebhusayithi: www.womicsteel.com

I-imeyili: sales@womicsteel.com

Ucingo/I-WhatsApp/I-WeChat: Victor: +86-15575100681 noma uJack: +86-18390957568