I-Womic Steel ikhiqize i-PrecisionAmapayipi ensimbi adonswa ngokubandayo angenamthungo/amapayipi.

"Ukunemba" yinkampani Insimbi YaseWomic's Izici Zokusebenza. Phakathi kwazo: ipayipi lensimbi elingenamthungo elincane ububanzi bangaphandle bungafinyelelwa, ubukhulu bodonga bungaba ngu-0.5mm-14mm. Isitoko sonyaka esingu-6*1mm, 8 *1mm, 10*1mm, 3mm-50mm, ipayipi lensimbi elingenamthungo elincane, lingafakwa ngaphandle komoya-mpilo. Isikhathi sokwenza ngokwezifiso siyashesha. "Ukunemba" kunembile kakhulu, ukubekezelela ububanzi bangaphakathi kungaba izintambo ezi-5, ukugxila okungu-0.1, ukuqeda okungu-0.4 noma ngaphezulu, kanye nokulingana okungu-0.1. "Okukhethekile" kuyinto ekhethekile. Zonke izinhlobo zensimbi ye-alloy: 30 crmn5, 20 CRMN, 16 mn, 15 crmo, 20 crmo, 30 crmo, 42 crmo, 37 mn5, mn2 20, 20 mn, mn2 40, 65 m, 17-4, 10 Cr17, 1 cr13, 2 cr13 kanye no-3 cr13, 1 Cr17, njenge-1Cr17Ni2. Zonke izinhlobo zamapayipi ensimbi angenamthungo zingafakwa ngaphandle komoya-mpilo, ukufakwa kwe-casing annealing, ukwelashwa kokupholisha kanye nezinye izidingo zobuchwepheshe. Ngaphezu kwalokho kungenziwa ngezifiso ngokwezidingo zamakhasimende zazo zonke izinhlobo zamapayipi ayisikwele, ipayipi eliyindilinga, ipayipi elinezinhlangothi eziyisithupha, ipayipi eliyindilinga langaphakathi eliyindilinga langaphandle, ipayipi eliyindilinga langaphakathi eliyisicaba langaphandle kanye namanye amapayipi ensimbi.

Ishubhu lensimbi elinokunemba okudonswe ngokubandayo liyishubhu lensimbi elinokunemba okuphezulu elenziwe ngenqubo yokudweba ebandayo, elinokunemba okuphezulu kanye nekhwalithi ephezulu yobuso. Nazi ezinye izici ezibalulekile kanye nezindawo zokusetshenziswa kweshubhu lensimbi elinokunemba okudonswe ngokubandayo:

Inqubo Yokukhiqiza: Inqubo yokukhiqiza ishubhu lensimbi eliqondile elidonswa ngokubandayo yenziwa ekushiseni kwegumbi, ngokudonsa ngokubandayo izinduku zensimbi eziqinile eziyindilinga noma amashubhu angenalutho izikhathi eziningi ukuze kufezwe ukunemba okudingekile kobukhulu kanye nokuphela kobuso.

Ukunemba kobukhulu: Ngenxa yokwelula nokukhipha ngesikhathi senqubo yokudweba ebandayo, ukulawulwa kobukhulu beshubhu yensimbi eqondile edonswayo ebandayo kuqinile kakhulu, futhi kungafinyelela izidingo zokunemba okuphezulu kakhulu, ngokuvamile ngaphakathi kwama-micron ambalwa.

Ikhwalithi yobuso: Ukuphela kobuso beshubhu yensimbi eqondile edonswa ngokubandayo kuphezulu kakhulu, ngokuvamile akudingi ukwelashwa kobuso okulandelayo, futhi kungasetshenziswa ngqo ezindaweni zokusetshenziswa ezifunwa kakhulu.

Ukukhethwa kwezinto: Izinto ezivame ukusetshenziswa zifaka phakathi insimbi yekhabhoni, insimbi ye-alloy, insimbi engagqwali, njll. Amashubhu ensimbi adonswe ngokucophelela abandayo ezinto ezahlukene angakhethwa ngokuya ngendawo ethile yokusetshenziswa kanye nezidingo.

Izindawo Zokusebenza: Amashubhu ensimbi aqondile adonswa ngokubandayo asetshenziswa kabanzi ekukhiqizeni izimoto, ezindizayo, ekukhiqizeni imishini, imishini kagesi, izimboni ze-petrochemical kanye neminye imboni. Kulezi zinsimu, amashubhu ensimbi aqondile adonswa ngokubandayo avame ukusetshenziselwa ukukhiqiza izingxenye nemishini enembile kakhulu futhi efunwa kakhulu njengama-bearings, imiphini yokudlulisa imoto, amasilinda e-hydraulic, kanye nezinsimbi ezinembile.

Ukusetshenziswa kwamapayipi ensimbi anembile:

Ukuthuthwa Kwepayipi, Ipayipi Lebhoyila, Ipayipi Le-Hydraulic/Imoto, Ukubhoboza Uwoyela/Igesi, Imboni Yemishini, Imboni Yamakhemikhali, Ukumba, Ukwakha Nokuhlobisa, Inhloso Ekhethekile

Izinzuzo: Uma kuqhathaniswa namashubhu ensimbi aguqiswayo noma akhishwa ngokushisa, amashubhu ensimbi aqondile adonswa ngokubandayo anezinzuzo zokuzinza okuhle kobukhulu, ukuqeda okuphezulu kwangaphakathi nangaphandle, kanye nezakhiwo ezinhle kakhulu zemishini, ezingathuthukisa ukumelana nokuguguleka, ukumelana nokugqwala kanye nokuphila kwenkonzo yomkhiqizo.

Ngamafuphi, amashubhu ensimbi aqondile adonswa ngokubandayo adlala indima ebalulekile ekukhiqizeni kwesimanje ngokunemba kwawo okuphezulu, ikhwalithi ephezulu kakhulu kanye nezinkambu zokusetshenziswa ezibanzi, enikeza izixazululo ezinokwethenjelwa kanye nokukhethwa kwezinto ezisebenzayo kwamaphrojekthi ahlukahlukene obunjiniyela.

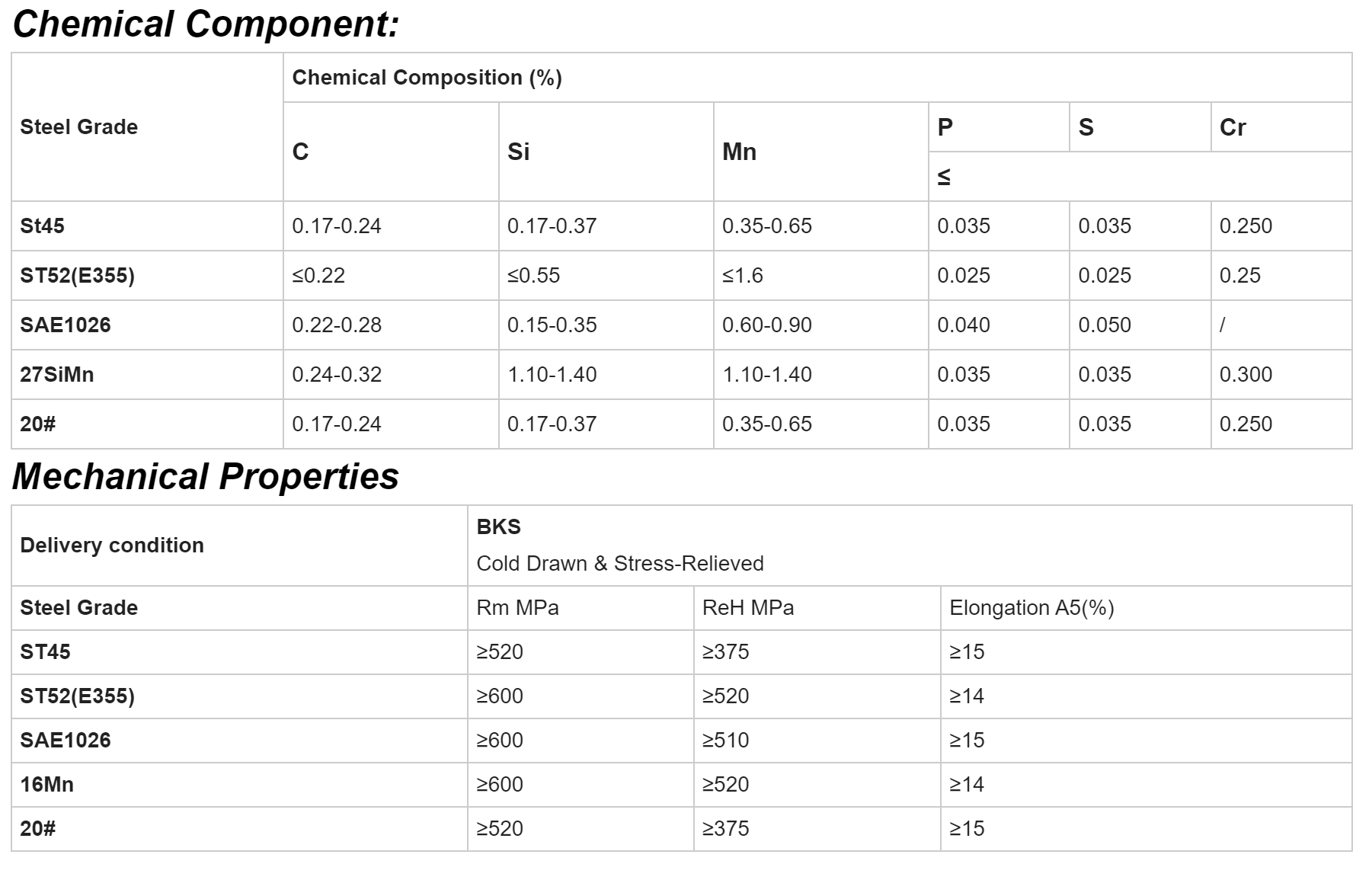

Amazinga / Izinto zeamashubhu ensimbi anembile:

En 10305-1, I-DIN2391, i-En10305, i-JIS G3445, I-ASTM A519, GB/T 8713, ST45, ST52, E355, E355SR, STKM13C, SAE1026, 20#, Q235B, CK45…

Ipayipi Lensimbi Yesilinda Yesilinda Engenamthungo E-10305-1 E215 E235 E355 Elicwengekileyo Elingenamthungo Le-Hydralic Cylinder

I-EN10305-1 E235 ipayipi elingenamthungo elijwayelekile laseYurophu elinobubanzi obuncane elidonswa ngokubandayo

I-EN 10305-1-2016 Izimo zobuchwepheshe zokulethwa kwamapayipi ensimbi ezinsimbi ezinembile Amapayipi ensimbi adonswa ngokubandayo angenamthungo

EnyeIzindinganiso zokusebenzisa amashubhu/amapayipi ensimbi akhiqizwa yiWomic Steel:

Amapayipi ensimbi angenamthungo e-GB3087-2008 amabhoyila anomfutho ophansi nophakathi

Amapayipi ensimbi ahlanganisiwe e-GB/T3091-2008 okuthuthwa koketshezi olunomfutho ophansi

GB/T3639-2000 Amapayipi ensimbi angenamthungo adonswa ngokubandayo noma abandayo

Amapayipi ensimbi angenamthungo e-GB5310-2008 ama-boilers anomfutho ophezulu

Amapayipi ensimbi angenamthungo e-GB/T8162-2008 ezakhiwo ezijwayelekile

Amapayipi ensimbi angenamthungo e-GB/T8163-2008 okuhambisa uketshezi

Amapayipi ensimbi angenamthungo e-GB5310-2008 ama-boilers anomfutho ophezulu

Amapayipi ensimbi yekhabhoni e-GB/T5312-2009 kanye namapayipi ensimbi angenamthungo ensimbi yekhabhoni e-manganese yemikhumbi

Amapayipi ensimbi angenamthungo e-GB6479-2000 emishini yomanyolo ocindezelayo

GB/T9711.1-1997 Amapayipi ensimbi embonini kawoyela negesi Ingxenye 1: Amapayipi ensimbi ebanga A

Amapayipi ensimbi angenamthungo e-GB/T9808-2008 okubhoboza

Amapayipi ensimbi angenamthungo e-GB9948-2006 okuqhekeka kwephethiloli

Amapayipi ensimbi angenamthungo e-GB/T17396-2009 e-Hot-rolled for hydraulic props

GB/T18984-2003 Amapayipi ensimbi angenamthungo amapayipi anokushisa okuphansi

GB/T19830-2005 Amapayipi ensimbi ekheji likawoyela negesi noma amapayipi kawoyela embonini kawoyela negesi

Amapayipi ensimbi angenamthungo e-GB/T20409-2006 anezintambo zangaphakathi zamabhoyila anomfutho ophezulu

I-GB/T20801-2006 Imininingwane yamapayipi okucindezela Amapayipi ezimboni

GB 24512.1-2009 Amapayipi ensimbi angenamthungo ezitshalweni zamandla enuzi Ingxenye 1 Amapayipi ensimbi engenamthungo ensimbi yekhabhoni

Amapayipi ensimbi angenamthungo e-GB 24512.2-2009 ezitshalo zamandla enuzi Ingxenye II Insimbi Ehlanganisiwe Ipayipi Elingenamthungo

Ipayipi Lensimbi Elingenamthungo le-GB/T 24591-2009 Le-Heater Yokugeleza Amanzi Engcindezi Ephezulu

Ipayipi Lensimbi Engenamthungo Ye-GJB 2608-96 Eqinile Yensimbi Yendiza Yesakhiwo

Ipayipi Elingenamthungo le-YB/T4146-2006 (YB/Z12-1977, GB/T18254-2002) Lensimbi Engenamthungo

Ipayipi Lensimbi engu-09CrCuSb(ND) Yokumelana Nokugqwala Kwe-Sulfuric Acid Dew Point (GB150-1998)

Ipayipi Lensimbi Elingenamthungo le-CB*3075-87 Marine

I-API Spec 5CT-2005 Casing kanye ne-Oyili Pipe Spec

I-API Spec 5L-2007 Umugqa Wepayipi Imininingwane

Ipayipi Lensimbi Elihlanganisiwe Nelingenamthungo le-ASTM A53/ASME SA53 Elimnyama Nelishisayo Elicwiliswe Nge-Galvanized Nelingenamthungo

Ipayipi Lensimbi Yekhabhoni Elingenamthungo le-ASTM A106/ ASME SA106 Lokushisa Okuphezulu

Ipayipi lensimbi ye-ASTM A179/ASME SA179 elingenamthungo elidonswa nge-carbon ephansi elinomoya ophansi lama-heat exchanger nama-condenser

I-ASTM A192/ASME SA192 Ishubhu yebhoyila yensimbi yekhabhoni engenamthungo yemishini yokucindezela okuphezulu

Ipayipi lensimbi ye-ASTMA199/ASME SA199 elidonswe ngokubandayo elingenamthungo lama-heat exchanger nama-condenser

I-ASTMA200/ASME SA200 Ishubhu lesithando sensimbi esingenamthungo esiphakathi nendawo se-alloy sezindawo zokuhluza

Ipayipi lensimbi ye-ASTM A210/ASME SA210 elingenamthungo lama-boiler nama-superheater

Ipayipi lensimbi ye-ASTM A213/ASME SA213 elingenamthungo le-ferritic ne-austenitic alloy lama-boiler, ama-superheater kanye nama-heat exchanger

Ipayipi lensimbi le-ASTM A333/ASME SA333 elingenamthungo nelihlanganisiwe lemishini yokushisa okuphansi

I-ASTM A334/ASME SA334 Ipayipi lensimbi yekhabhoni nele-alloy elingenamthungo nelihlanganisiwe lokushisa okuphansi

Ipayipi lensimbi ye-ASTM A335/ASME SA335 elingenamthungo le-ferritic alloy yokushisa okuphezulu

Amapayipi esakhiwo sensimbi yekhabhoni ahlanganisiwe futhi angenamthungo e-ASTMA500/ASME SA500 ayindilinga futhi anomumo okhethekile afakwe ngendlela ebandayo

Amapayipi ensimbi yekhabhoni angenamthungo e-ASTM A519/ASME SA519 kanye namapayipi ensimbi e-alloy emishini

Amapayipi ensimbi yekhabhoni adonswa ngokubandayo e-ASTM A556/ASME SA556M angenamthungo asetshenziselwa ukushisa amanzi

Amapayipi ensimbi angenamthungo e-BS 3059 ama-boiler nama-superheater

Amapayipi ensimbi yekhabhoni e-BS 3601-1987 anezakhiwo ezithile zokushisa kwegumbi zokucindezela

Amapayipi ensimbi acindezelwe e-BS 3602-1. Amapayipi ensimbi ensimbi yekhabhoni kanye ne-carbon manganese anezakhiwo ezithile zokushisa okuphezulu.

Imininingwane ye-BS 6323-4 yamapayipi ensimbi angenamthungo nashibilikisiwe okukhiqiza izimoto, ukukhiqizwa kwemishini kanye nobunjiniyela obujwayelekile. Ingxenye 4: Amapayipi ensimbi angenamthungo aqinisiwe abandayo

BS EN 10208-1-1998 Amapayipi ensimbi epayipi eliwuketshezi elivuthayo. Izimo zokufaka zobuchwepheshe. Amapayipi adingekayo ebanga A.

I-EN 10210-1-2006 Izingxenye zesakhiwo eziqediwe ezishisayo nezingenalutho zensimbi zesakhiwo ezingezona i-alloy kanye nezinhlayiya ezincane Ingxenye 1

I-EN 10216-1 Amashubhu ensimbi angenamthungo ngezinjongo zokucindezela Ingxenye 1: Amashubhu ensimbi angewona angxube anezakhiwo ezithile zokushisa kwegumbi

I-EN 10216-2 Amashubhu ensimbi angenamthungo ngezinjongo zokucindezela Ingxenye 2: Amashubhu ensimbi angewona a-alloy kanye ne-alloy anezakhiwo ezithile zokushisa eziphakeme

I-EN 10255-2004 Amashubhu ensimbi angewona a-alloy afanelekela ukushisela nokufaka intambo

I-EN 10297-1 Amashubhu ensimbi ayindilinga angenamthungo ngezinjongo zobunjiniyela bemishini kanye nobunjiniyela obujwayelekile

I-EN 10305-1 Izimo zokulethwa kobuchwepheshe zamapayipi ensimbi angenamthungo anembile Ingxenye 1: Amapayipi ensimbi abandayo adonswa ngaphandle komthungo

Amashubhu ayisiyingi angenamthungo ensimbi angenangxube e-DIN 1629 anezidingo zekhwalithi ekhethekile

Amashubhu angenamthungo ensimbi yekhabhoni eyindilinga esebenza kahle kakhulu i-DIN 1630

I-DIN 2391 Amashubhu ensimbi angenamthungo adonswa ngokubandayo noma abandayo

Amashubhu ensimbi angenamthungo e-DIN 2448. Ithebula elijwayelekile lobukhulu kanye nesisindo ngobude beyunithi ngayinye

I-DIN 17172-1991 Izimo zobuchwepheshe zokulethwa kwamapayipi ensimbi okuhambisa uketshezi namagesi avuthayo

Amapayipi ensimbi angenamthungo e-DIN 17175 enziwe ngensimbi engashisi

Amapayipi ensimbi ayindilinga angenamthungo e-DIN 17204

Amapayipi ensimbi e-JIS G3441 e-alloy ezakhiwo zemishini

Amapayipi ensimbi yekhabhoni e-JIS G3444-2004 ezakhiwo ezijwayelekile

Amapayipi ensimbi yekhabhoni e-JIS G3445 ezakhiwo ezivamile

Amapayipi ensimbi yekhabhoni e-JIS G3452 (SGP) amapayipi ajwayelekile

Amapayipi ensimbi yekhabhoni e-JIS G3454 amapayipi okucindezela

Amapayipi ensimbi yekhabhoni e-JIS G3455-2005 okufaka amapayipi anomfutho ophezulu

Amapayipi ensimbi yekhabhoni e-JIS G3456-2004 okufaka amapayipi okushisa okuphezulu

Amapayipi ensimbi e-alloy e-JIS G3458 okufaka amapayipi

Amapayipi ensimbi e-JIS G3460-2006 amapayipi anezinga lokushisa eliphansi

Amapayipi ensimbi e-JIS G3461 ama-boilers kanye nama-heat exchanger

Amapayipi ensimbi e-JIS G3462 e-alloy ama-boilers kanye nama-heat exchanger

Amapayipi ensimbi e-JIS G3464-2006 okushintshanisa ukushisa kwemishini yokushisa okuphansi

Amapayipi ensimbi e-JIS G3467-2006 okushisa izitofu

Amapayipi ensimbi yekhabhoni e-JIS G3473-2007 emiphongolweni yesilinda

Amapayipi ensimbi yekhabhoni e-JIS G3475-2008 ezakhiwo zokwakha

I-JIS G4051 Insimbi yekhabhoni yezakhiwo zemishini

I-JISG4053-2003 Insimbi e-alloy ephansi yezakhiwo zomshini

Amapayipi ensimbi angenamthungo e-JIS G7215-2003 emishini eneziphetho ezibushelelezi (incazelo ye-ISO)

Amapayipi ensimbi angenamthungo e-JIS G7219-2003 okucindezela. Ingxenye 1: Insimbi engeyona i-alloy enezakhiwo ezithile zokushisa kwegumbi (incazelo ye-ISO)

Amapayipi ensimbi angenamthungo e-JIS G7220-2003 okucindezela. Ingxenye 2: Insimbi engaxutshwe ne-alloy kanye nensimbi engaxutshwe ne-alloy enezakhiwo ezithile zokushisa okuphezulu (incazelo ye-ISO)

Amapayipi ensimbi angenamthungo e-JIS G7221-2003 okucindezela. Ingxenye 3: Insimbi engaxutshwe ne-alloy kanye nensimbi engaxutshwe ne-alloy enezakhiwo ezithile zokushisa okuphansi (incazelo ye-ISO)

Amapayipi abushelelezi angenamthungo ensimbi engeyona i-alloy ye-NF A 49-211 yamapayipi okudlulisa uketshezi olushisayo olusezingeni eliphezulu

Amapayipi ensimbi angenamthungo e-NF A 49-213 ensimbi engeyona i-alloy kanye nensimbi ye-molybdenum kanye ne-chromium-molybdenum angenamthungo okushisa okuphezulu

I-NF A 49-215-1981 Amapayipi ensimbi angenamthungo kanye nensimbi ye-ferritic alloy yensimbi engenamthungo yama-heat exchanger

Amapayipi ensimbi angenamthungo e-GOST 550-75 okucubungula uphethiloli kanye nomkhakha we-petrochemical

Amapayipi ensimbi angenamthungo emishini eneziphetho ezibushelelezi ze-ISO 2937-1974

I-ISO 11960:2001 Amapayipi ensimbi okufaka imbobo yemithombo kawoyela kanye namapayipi embonini kaphethiloli kanye negesi yemvelo

ISO 3183:2007 Izimboni zikaphethiloli negesi yemvelo: Amapayipi ensimbi ezinhlelo zokuthutha amapayipi

ISO 9329-1:1989 Amashubhu ensimbi angenamthungo ngezinjongo zokucindezela Ingxenye 1: Izinsimbi ezingezona i-alloy ezinezakhiwo ezithile zokushisa kwegumbi

I-ISO 9329-2:1997 Amashubhu ensimbi angenamthungo ngezinjongo zokucindezela Ingxenye 2: Izinsimbi ezingezona i-alloy kanye nezinsimbi ze-alloy ezinezakhiwo ezithile zokushisa eziphakeme

ISO 9329-3:1997 Amashubhu ensimbi angenamthungo ngezinjongo zokucindezela Ingxenye 3: Izinsimbi ezingezona i-alloy kanye nezinsimbi ze-alloy ezinezakhiwo ezithile zokushisa okuphansi

Isikhathi sokuthunyelwe: Juni-27-2024