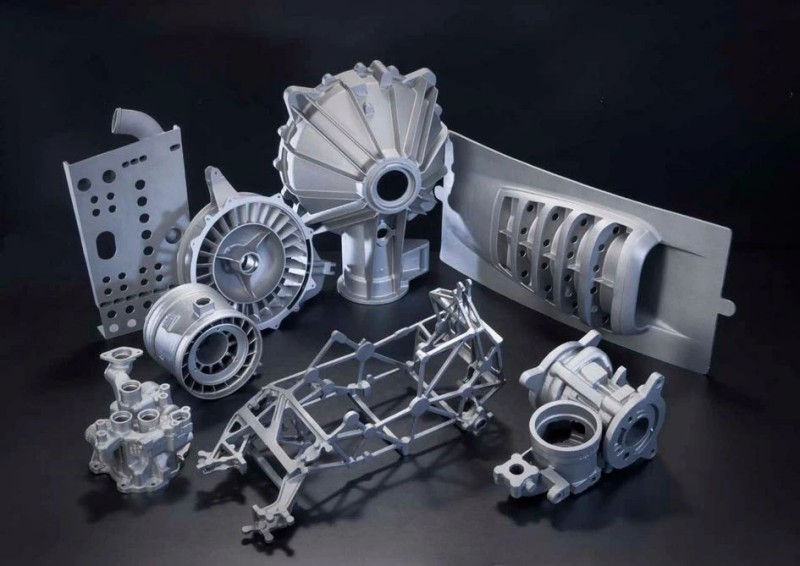

Ukubuka Konke Kwezinto Ezihlanganisiwe

Incazelo ye-Alloy

I-alloy iyinhlanganisela efanayo eyakhiwe ngezinsimbi ezimbili noma ngaphezulu, noma inhlanganisela yezinsimbi nezinto ezingezona ezensimbi, ezinezici zensimbi. Umqondo ngemuva komklamo we-alloy ukuhlanganisa izinto ngendlela yokuthi kuthuthukiswe izakhiwo zemishini, zomzimba, nezamakhemikhali ukuze kuhlangatshezwane nezidingo ezithile zezicelo ezahlukene.

Ukuhlukaniswa Kwezinto Ezihlanganisiwe

Izinto ze-alloy zingahlukaniswa ngokusekelwe ezintweni eziyinhloko kanye nezakhiwo zazo kanje:

●Izingxube Zensimbi:Lezi yizingxube ezisekelwe ensimbini ezinezinto ezengeziwe njengekhabhoni, i-manganese, ne-silicon, ezisetshenziswa kakhulu embonini yokwenza insimbi nokukhipha insimbi.

●Ama-Alloy e-Aluminium:Lezi yizingxube ezisekelwe ku-aluminium ezinezici ezifana nethusi, i-magnesium, ne-zinc, ezaziwa ngokuba lula, ziqinile, futhi zinezakhiwo ezinhle kakhulu zokuhambisa kanye nokushisa.

●Izingxube Zethusi:Lezi yizingxube ezisekelwe ethusi ezinezici ezengeziwe ezifana ne-zinc, i-tin, kanye ne-lead, ezinikeza ukuhanjiswa okuhle, ukumelana nokugqwala, kanye nokusebenza kahle.

●Ama-Alloy e-Magnesium:Ama-alloy asekelwe ku-magnesium, ngokuvamile ahlanganiswe ne-aluminium, i-zinc, ne-manganese, ayizinsimbi zesakhiwo ezilula kakhulu ezinokumelana okuhle nokushaqeka kanye nokushaqeka kokushisa.

●Ama-alloy e-Nickel:Ama-alloy asekelwe ku-nickel aqukethe izinto ezifana ne-chromium, insimbi, ne-cobalt, futhi abonisa ukumelana nokugqwala okuvelele kanye nokusebenza kahle kokushisa okuphezulu.

● Ama-alloy e-Titanium:Eyaziwa ngamandla ayo aphezulu, ukuminyana okuphansi, kanye nokumelana nokugqwala okumangalisayo, ama-alloy asekelwe ku-titanium asetshenziswa kabanzi ekusetshenzisweni kwezindiza.

Ama-alloy e-Ferrous

Ukwakheka kanye Nezakhiwo Ze-Ferrous Alloys

Ama-alloy e-ferrous akhiwe ngensimbi enezinto ezahlukahlukene zokuhlanganisa ezithuthukisa izakhiwo zazo zemishini. Izinto ezivamile zifaka:

●Ikhabhoni:Esinye sezakhi ezibaluleke kakhulu zokuhlanganisa, okuqukethwe kwekhabhoni okuhlukahlukene kuma-alloy e-ferrous kuthinta ubulukhuni kanye nokuqina. Ama-alloy anekhabhoni ephezulu anikeza ubulukhuni obuningi kodwa ukuqina okuncane.

●I-Silicone:I-silicon ithuthukisa amandla nokuqina kwama-alloy e-ferrous futhi ivame ukusetshenziswa kuma-alloy e-silicon-iron ekwenzeni insimbi njenge-deoxidizer kanye ne-alloying agent.

●I-Manganese:I-Manganese ibalulekile ekwandiseni amandla nokuqina kwezinsimbi zensimbi, kanti izinsimbi zensimbi zensimbi zibalulekile ekuthuthukiseni ukumelana nokuguguleka kwensimbi.

●I-Chromium:Ama-alloy e-Chromium-iron ahlinzeka ngokumelana okuhle kakhulu nokugqwala kanye namandla okushisa aphezulu, avame ukusetshenziswa ekukhiqizweni kwensimbi engagqwali kanye nezinsimbi ezikhethekile.

Ukusetshenziswa kwe-Ferrous Alloys

Ama-alloy e-ferrous asetshenziswa kabanzi emikhakheni eyahlukene, okuhlanganisa:

●Imboni Yokwenza Insimbi:Ama-alloy e-ferrous ayizithasiselo ezibalulekile ekukhiqizweni kwensimbi, asetshenziselwa ukuguqula ukwakheka kwensimbi nokuthuthukisa izakhiwo zayo.

●Imboni Yokuphonsa:Ezinqubweni zokubumba, ama-alloy e-ferrous athuthukisa izakhiwo zemishini kanye nokuqina kwemikhiqizo yensimbi ephonswe.

●Izinto Zokushisela:Ama-alloy e-ferrous asetshenziswa ekukhiqizweni kwezinduku zokushisela kanye ne-flux ukuqinisekisa ukuthi amalunga okushisela asezingeni eliphezulu.

●Izimboni Zamakhemikhali Nomanyolo:Ama-alloy e-ferrous asebenza njengezinto ezibangela ukuvuvukala kanye nezinto ezinciphisa uketshezi ekukhiqizweni kwamakhemikhali kanye nomanyolo.

●Ukusebenza ngensimbi:Ama-alloy e-ferrous asetshenziswa kumathuluzi anjengezinsimbi zokusika kanye nezikhunta, okuthuthukisa ukuqina nokusebenza kahle kwazo.

Ama-Alloys e-Aluminium

Izici Eziyinhloko Zama-Aluminium Alloys

Ama-alloy e-aluminium adumile ngokukhanya kwawo, amandla aphezulu, kanye nokulula kokucutshungulwa, okwenza abe abalulekile ezimbonini zanamuhla. Izici ezibalulekile zifaka:

●Ilula:Ama-alloy e-aluminium anobukhulu obuphansi obungaba ngu-2.7 g/cm³, okwenza abe mahle kakhulu ekusetshenzisweni okudinga ukunciphisa isisindo.

● Amandla Aphezulu:Ngokusebenzisa i-alloy kanye nokwelashwa ngokushisa, ama-alloy e-aluminium angafinyelela amandla aphezulu okudonseka, kanti amanye ama-alloy adlula ama-500 MPa.

●Ukusebenza Okuhle Kakhulu:I-aluminiyamu emsulwa iyisiqhubi esihle kakhulu sikagesi nokushisa, futhi ama-alloy e-aluminiyamu agcina ingxenye enkulu yalezi zakhiwo.

●Ukumelana Nokugqwala:Ungqimba lwe-oxide yemvelo lwakha phezu kwe-aluminium alloys, oluhlinzeka ngokumelana okuhle kakhulu nokugqwala, futhi ukwelashwa okukhethekile kungathuthukisa kakhulu lesi sici.

●Ukusebenza Kalula:Ama-alloy e-aluminium abonisa ukuqina okuhle, okwenza afaneleke ezinqubweni zokuthunga, zokukhipha, nezokwakha.

Amabanga kanye nokusetshenziswa kwe-Aluminium Alloys

Ama-alloy e-aluminium ahlukaniswa ngokusekelwe ezintweni zawo eziyinhloko zokuhlanganisa kanye nezakhiwo. Amanye amamaki avamile afaka:

●Uchungechunge lwe-1xxx:I-aluminiyamu emsulwa, enokuqukethwe kwe-aluminiyamu okungaphezu kuka-99.00%, esetshenziswa kakhulu embonini kagesi kanye nezimpahla zansuku zonke ezisetshenziswayo.

●2xxx Uchungechunge:Ithusi liyisici esiyinhloko sokuxuba, esithuthukisa kakhulu amandla ngemva kokwelashwa ngokushisa, esivame ukusetshenziswa ezinhlotsheni zezindiza.

●Uchungechunge lwe-3xxx:I-Manganese iyisici esiyinhloko sokuxuba, esinikeza ukumelana okuhle nokugqwala, esetshenziswa kabanzi ekwakheni nasezintweni zokwakha.

●Uchungechunge lwe-4xxx:I-silicon iyinto eyinhloko yokuhlanganisa, enikeza ukumelana nokushisa kanye nezakhiwo ezinhle zokushisela, efanelekile ezintweni zokushisela kanye nezingxenye ezimelana nokushisa.

●Uchungechunge lwe-5xxx:I-magnesium iyisici esiyinhloko sokuxuba, esinikeza izakhiwo ezinhle kakhulu zemishini kanye nokumelana nokugqwala, esetshenziswa ezimbonini zasolwandle, zezimoto, kanye nezezindiza.

●Uchungechunge lwe-6xxx:I-magnesium ne-silicon yizinto eziyinhloko zokuhlanganisa, ezinikeza amandla amahle nokusebenza kahle, ezivame ukusetshenziswa ezintweni zokwakha.

●Uchungechunge lwe-7xxx:I-Zinc iyinto eyinhloko yokuhlanganisa, futhi lezi zinhlobo ze-alloy zinikeza amandla aphezulu kakhulu, asetshenziswa kakhulu ezakhiweni zezindiza kanye nezicelo zamandla aphezulu.

●Uchungechunge lwe-8xxx:Iqukethe ezinye izinto ezifana nensimbi ne-nickel, ezinikeza amandla amahle kanye nokuqhuba kahle, ezisetshenziswa kakhulu embonini kagesi.

Ama-aluminium alloys asetshenziswa emikhakheni eyahlukene, okuhlanganisa:

●Indawo Yezindiza:Ama-alloy e-aluminium alula futhi anamandla aphezulu abalulekile ezakhiweni zezindiza kanye nezingxenye zazo.

●Ezokuthutha:Ama-alloy e-aluminium asetshenziselwa ukukhiqiza izingxenye zezimoto ezilula kanye nezesitimela, okuthuthukisa ukusetshenziswa kahle kukaphethiloli.

●Imboni Kagesi:I-Aluminium iyinto ethandwa kakhulu ngamakhebula nama-transformer

●Ukwakhiwa:Ama-alloy e-aluminium asetshenziswa kabanzi ezakhiweni zezakhiwo, ozimele bamafasitela, iminyango, kanye nophahla ngenxa yamandla awo, ukumelana nokugqwala, kanye nokubukeka okuhle.

●Ukupakisha:Ama-alloy e-aluminium, ikakhulukazi ngesimo sama-foil namathini, asetshenziswa kakhulu embonini yokupakisha ngoba alula, awanobuthi, futhi angaphinde asetshenziswe kakhulu.

Ama-Alloy Ethusi

Ukwakheka kanye Nezakhiwo Ze-Copper Alloys

Ama-alloy ethusi aziwa ngokusebenza kwawo kahle kakhulu kukagesi nokushisa, ukumelana nokugqwala, kanye nokulula kokukhiqizwa. Ama-alloy ethusi avamile afaka:

●Ithusi (Ingxubevange Yethusi-Izinki):Ithusi elaziwa ngamandla alo, ukuguquguquka kwalo, kanye nokumelana nokugqwala, livame ukusetshenziswa ezisetshenziswa kwemishini, kumapayipi, nasezintweni zomculo.

●Ithusi (I-Copper-Tin Alloy):Le alloy inikeza ukumelana nokugqwala okuphezulu, ubulukhuni, kanye nokumelana nokuguguleka, okuvame ukusetshenziswa kuma-bearings, bushings, kanye nezicelo zasolwandle.

●Ama-Alloy Ethusi Ne-Nickel:Lezi zinhlobo ze-alloy zinikeza ukumelana okuhle kakhulu nokugqwala ezindaweni zasolwandle, okwenza zibe zilungele ukwakha imikhumbi, amapulatifomu asogwini lolwandle, kanye nezitshalo zokususa usawoti emanzini.

●Ithusi leBeryllium:Njengoba inamandla aphezulu, ubulukhuni, kanye nokumelana nokugqwala, ithusi le-beryllium livame ukusetshenziswa ezintweni zokunemba, izixhumi zikagesi, kanye neziphethu.

Ukusetshenziswa kwe-Copper Alloys

Ama-alloy ethusi akhonza izimboni eziningi ngenxa yokuguquguquka kwawo kanye nezakhiwo zawo ezihlukile:

●Imboni Kagesi:Ama-alloy ethusi asetshenziswa kabanzi ezixhumini zikagesi, izintambo, kanye nezingxenye ngenxa yokuqhuba kwawo kahle kakhulu.

●Ukuphathwa Kwamapayipi Noketshezi:Ithusi nethusi kuvame ukusetshenziswa kuma-valve, ama-fitting, kanye nezinye izinhlelo zokusebenza zamapayipi ngenxa yokumelana nokugqwala kwawo.

●Imboni Yasolwandle:Ama-alloy ethusi-nickel ayathandwa kakhulu ekusetshenzisweni olwandle ngenxa yokumelana kwawo okuhle kakhulu nokugqwala kwamanzi olwandle.

●Ubunjiniyela Bokunemba:Ithusi le-Beryllium lisetshenziswa kumathuluzi, imishini engashisi uphethiloli, kanye nezingxenye ezinembile ngenxa yamandla nokuqina kwalo.

Ama-Magnesium Alloys

Izici ze-Magnesium Alloys

Ama-alloy e-magnesium ayizinsimbi zesakhiwo ezilula kakhulu, ezinesilinganiso esihle kakhulu samandla-kuya-isisindo, ukumuncwa kokushaqeka, kanye nokusebenza kahle komshini. Izakhiwo ezibalulekile zifaka:

●Ilula:Ama-alloy e-magnesium alula ngo-35% kune-aluminium kanye no-78% alula kunensimbi, okwenza abe ngcono kakhulu ekusetshenzisweni okuzwela isisindo.

●Ukusebenza Kahle Kokusebenza:Ama-alloy e-magnesium anamandla amakhulu okusebenza, okuvumela ukuthi izingxenye eziyinkimbinkimbi nezinembile zenziwe kahle.

●Ukumuncwa Okushaqisayo:Lezi zinsimbi zinezakhiwo ezinhle zokumunca ukushaqeka, okwenza zibe usizo ezisetshenziswa ezimotweni nasezindizeni.

●Ukushabalalisa Ukushisa:Ama-alloy e-magnesium ahlinzeka ngokushabalalisa ukushisa okuphumelelayo, okubalulekile kuma-electronics kanye nezingxenye zokushisa okuphezulu.

Ukusetshenziswa kwe-Magnesium Alloys

Ngenxa yokukhanya kwawo namandla awo, ama-magnesium alloys asetshenziswa ezimbonini ezahlukene:

●Imboni Yezimoto:Ama-alloy e-magnesium asetshenziswa ezingxenyeni zenjini, ezindlini zokudlulisa amagiya, nasemasondoni ukunciphisa isisindo semoto nokuthuthukisa ukusebenza kahle kukaphethiloli.

●Imboni Yezindiza:Ama-alloy e-magnesium asetshenziswa ezingxenyeni zezindiza kanye nasezingxenyeni zezindiza lapho ukunciphisa isisindo kubaluleke kakhulu.

●Izinto zikagesi:Ama-alloy e-magnesium asetshenziswa ekwenziweni kwama-laptop alula, amakhamera, kanye namafoni aphathwayo ngenxa yamandla awo kanye nezakhiwo zawo zokususa ukushisa.

●Amadivayisi Ezokwelapha:Ama-alloy e-magnesium asetshenziswa ezifakelweni ezingaphili kanye namadivayisi amathambo ngenxa yokuhambisana kwazo nezinto eziphilayo.

Ama-alloy e-Nickel

Izakhiwo ze-Nickel Alloys

Ama-alloy e-nickel aziwa ngokumelana kwawo nokugqwala okumangalisayo, ukuzinza kokushisa okuphezulu, kanye namandla okusebenza. Ngokuvamile axutshwa ne-chromium, insimbi, nezinye izinto ukuze kuthuthukiswe ukusebenza ezindaweni ezibucayi. Izakhiwo ezibalulekile zifaka:

●Ukumelana Nokugqwala:Ama-alloy e-nickel amelana kahle kakhulu ne-oxidation kanye nokugqwala ezindaweni ezinzima, okuhlanganisa amanzi olwandle kanye nezimo ze-asidi.

●Amandla Okushisa Okuphezulu:Ama-alloy e-nickel agcina amandla awo emazingeni okushisa aphezulu, okwenza afaneleke ukusetshenziswa ezindizeni nasekukhiqizeni ugesi.

●Ukumelana Nokugqokwa:Ama-alloy e-nickel anikeza ukumelana okuhle nokuguguleka, okuwusizo ekusetshenzisweni okudinga ukuqina okuhlala isikhathi eside.

Ukusetshenziswa kwe-Nickel Alloys

Ama-alloy e-nickel asetshenziswa ezindaweni eziningi ezahlukene:

●Imboni Yezindiza:Ama-superalloy asekelwe ku-nickel asetshenziswa ezinjinini zejethi, ama-turbine blades, nakwezinye izingxenye zokushisa okuphezulu ngenxa yokumelana kwawo nokushisa.

●Ukucubungula Amakhemikhali:Ama-alloy e-nickel asetshenziswa kuma-reactor, kuma-heat exchanger, kanye nasezinhlelweni zamapayipi lapho ukumelana nokugqwala kanye namazinga okushisa aphezulu kubalulekile khona.

●Ukukhiqiza Amandla:Ama-alloy e-nickel asetshenziswa kuma-reactor enuzi kanye nama-gas turbine ngenxa yamakhono awo okushisa okuphezulu kanye nokumelana nokugqwala.

●Imboni Yasolwandle:Ama-alloy e-nickel asetshenziswa ezindaweni zasolwandle ukuze kusetshenziswe izinhlelo zokusebenza ezifana namaphampu, ama-valve, kanye nemishini yokukhipha usawoti emanzini olwandle.

Ama-alloy e-Titanium

Izici ze-Titanium Alloys

Ama-alloy e-titanium alula kodwa aqinile, anokumelana okuhle nokugqwala kanye nokuqina kokushisa okuphezulu. Izakhiwo ezibalulekile zifaka:

●Isilinganiso Esiphezulu Samandla Nesisindo:Ama-alloy e-titanium aqinile njengensimbi kodwa alula cishe ngo-45%, okwenza afaneleke kakhulu ezindiza nasezinhlelweni zokusebenza eziphezulu.

●Ukumelana Nokugqwala:Ama-alloy e-titanium anikeza ukumelana okuvelele kokugqwala, ikakhulukazi emanzini olwandle nasezindaweni zamakhemikhali.

●Ukuhambisana kwezinto eziphilayo:Ama-alloy e-titanium ahambisana ne-bio, okwenza afaneleke ezifakelweni zezokwelapha kanye namadivayisi.

●Ukuqina Kwezinga Lokushisa Eliphezulu:Ama-alloy e-titanium angamelana nokushisa okukhulu, alondoloze amandla awo kanye nobuqotho ezindaweni zokusebenzisa izindiza kanye nezimboni.

Ukusetshenziswa kwe-Titanium Alloys

Ama-alloy e-titanium asetshenziswa kabanzi ezimbonini lapho amandla aphezulu, ulula, kanye nokumelana nokugqwala kubalulekile khona:

●Imboni Yezindiza:Ama-alloy e-titanium asetshenziswa kumafreyimu ezindiza, izingxenye zenjini, kanye namagiya okufika ngenxa yamandla awo aphezulu kanye nokonga isisindo.

●Amadivayisi Ezokwelapha:Ama-alloy e-titanium asetshenziswa ekufakweni kwamathambo, ekufakweni kwamazinyo, kanye nasezintweni zokuhlinza ngenxa yokuhambisana kwazo kanye nokuqina kwazo.

●Imboni Yasolwandle:Ama-alloy e-titanium asetshenziswa ezingxenyeni zangaphansi kolwandle, ekwakheni imikhumbi, nasekubholeni ogwini ngenxa yokumelana kwawo nokugqwala.

●Izicelo Zezimboni:Ama-alloy e-titanium asetshenziswa ezitshalweni zokucubungula amakhemikhali, ekukhiqizeni ugesi, nasezintweni ezisetshenziswa ezimotweni zezingxenye ezidinga amandla nokumelana nokugqwala.

Isiphetho

Izinto ze-alloy zidlala indima ebalulekile ezimbonini zanamuhla, zinikeza izixazululo ezenzelwe wena ngenhlanganisela eyingqayizivele yamandla, isisindo, ukumelana nokugqwala, kanye nokuqina. Kusukela ezindiza kuya kwezimoto, ukwakhiwa kuya kumadivayisi ezokwelapha, ukuguquguquka kwezinto ze-alloy kuzenza zibe yinto ebaluleke kakhulu ekusetshenzisweni okuningi. Kungakhathaliseki ukuthi amandla aphezulu e-alloy ensimbi, izakhiwo ezilula ze-alloy ze-aluminium, noma ukumelana nokugqwala kwe-nickel ne-titanium alloys, ama-alloy enziwe ngendlela yokuhlangabezana nezidingo ezahlukahlukene zomhlaba wanamuhla othuthukile kwezobuchwepheshe.

Isikhathi sokuthunyelwe: Okthoba-17-2024