1. Ukubuka Konke Komkhiqizo

Iladi lensimbi elenziwe ngokuhambisanaI-ASTM A27 Ibanga 70-36iwumshini wokusika insimbi yekhabhoni onzima owenzelwe ukuphatha, ukuthutha, kanye nokugcina okwesikhashana i-slag encibilikisiwe noma izinto ezishisayo ezisetshenziswayo zensimbi kanye nezimboni.

Leli banga likhethwe ngokukhethekile ukuze linikeze ibhalansi efanele phakathiamandla, ukuguquguquka, kanye nokumelana nokucindezeleka kokushisa nokomshini, okwenza ifaneleke kakhulu ezindizeni eziqhutshwa imisebenzi yokuphakamisa ephindaphindwayo, ukujikeleza kokushisa, kanye nokulayisha ngomfutho.

2. Izinga Elisebenzayo

I-ASTM A27 / A27M– Izinsimbi Zokubumba, Ikhabhoni, Zokusetshenziswa Okuvamile

Ibanga Lezinto:I-ASTM A27 Ibanga 70-36

Zonke izinto ezibunjiwe kufanele zikhiqizwe, zihlolwe, futhi zihlolwe ngokuhambisana ngokugcwele nezidingo ze-ASTM A27 ngaphandle kokuthi kuchazwe ngenye indlela ngumthengi.

3. Izici Zezinto Ezibalulekile – Ibanga 70-36 le-ASTM A27

I-ASTM A27 Grade 70-36 iyizinga lokuphonswa kwensimbi yekhabhoni elinamandla aphakathi elibonakala ngokuqina okuhle kanye nokuthembeka kwesakhiwo.

3.1 Izakhiwo Zemishini (Okungenani)

| Impahla | Isidingo |

| Amandla Okudonsa | ≥ 70,000 psi (≈ 485 MPa) |

| Amandla Okukhiqiza | ≥ 36,000 psi (≈ 250 MPa) |

| Ukwelulwa (ngamasentimitha angu-2/50) | ≥ 22% |

| Ukunciphisa Indawo | ≥ 30% |

Lezi zakhiwo zemishini ziqinisekisa amandla anele okuthwala umthwalo ngenkathi zigcina ukumelana okuhle kakhulu nokuqhekeka nokuqhekeka okuqhekekayo.

3.2 Ukwakheka Kwamakhemikhali (Imikhawulo Ejwayelekile)

| Isici | Okuqukethwe Okuphezulu |

| Ikhabhoni (C) | ≤ 0.35% |

| I-Manganese (Mn) | ≤ 0.70% |

| I-Phosphorus (P) | ≤ 0.05% |

| I-Sulfur (S) | ≤ 0.06% |

Okuqukethwe kwekhabhoni ne-manganese okulawulwayo kunegalelo ekhwalithini yokubumba ezinzile kanye nokusebenza okuthembekile kwemishini ngaphandle kwesidingo sokuxuba izakhi.

4. Umklamo kanye nezici zesakhiwo se-Ladle

l Umzimba owodwa ohlanganisiwe noma umzimba ohlanganisiwe onezingwegwe zokuphakamisa ezihlanganisiwe / ama-lug okuphakamisa

l Smooth geometry yangaphakathi ukuze unciphise ukuhlushwa kokucindezeleka

l Ubukhulu bodonga obanele obuklanyelwe ukumelana nokushisa okukhulu kanye nemithwalo yokuphatha ngomshini

Izindawo zokuphakamisa eziklanywe ngokusekelwe ezimweni zokuphakamisa umthwalo ogcwele, kufaka phakathi izici zokuphepha

Umklamo wendebe ugcizelelaubuqotho besakhiwo kanye nokuqina kwenkonzo, ikakhulukazi lapho kutholakala ukushisa okuphezulu kanye nokuphathwa kwe-crane okuphindaphindiwe.

5. Inqubo Yokukhiqiza

5.1 Indlela Yokuphonsa

l Ukuphonswa kwesihlabathi kusetshenziswa izinto zokubumba ezilawulwayo ezifanele ukuphonswa kwensimbi kwesigaba esikhulu

l Ukuphonswa kokushisa okukodwa kuyanconywa ukuqinisekisa ukungaguquguquki kwamakhemikhali

5.2 Ukuncibilikisa Nokuthulula

l Isithando somlilo se-arc kagesi (i-EAF) noma isithando somlilo sokungenisa

l Ukulawulwa okuqinile kokwakheka kwamakhemikhali ngaphambi kokuthulula

l Ukushisa okuthululwayo okulawulwayo ukuze kuncishiswe amaphutha angaphakathi

5.3 Ukwelashwa Kokushisa

Ukulungisa ukwelashwa kokushisakuvame ukusetshenziswa

Inhloso:

l Cwenga isakhiwo sokusanhlamvu

l Thuthukisa ukuqina kanye nezakhiwo ezifanayo zemishini

l Ukuqeda ukucindezeleka kwangaphakathi kokuphonsa

Imingcele yokwelashwa kokushisa kufanele ibhalwe phansi futhi ilandelelwe.

6. Ukulawulwa Kwekhwalithi Nokuhlolwa

6.1 Ukuhlaziywa Kwamakhemikhali

l Ukuhlaziywa kokushisa okwenziwa ngokuncibilika ngakunye

Imiphumela eqoshwe kuSitifiketi Sokuhlolwa Kwesigayo (i-MTC)

6.2 Ukuhlolwa Kwemishini

l Amakhuphoni okuhlola aphonswe ekushiseni okufanayo kanye nokulungiswa kokushisa kanye nendebe:

Ukuhlolwa kwe-Tensile

Ukuqinisekiswa kwamandla okukhiqiza

l Ukwelulwa nokunciphisa indawo

6.3 Ukuhlolwa Okungabhubhisi (njengoba kusebenza)

Kuye ngezidingo zephrojekthi:

Ukuhlolwa okubonakalayo (100%)

Ukuhlolwa Kwezinhlayiya Ze-Magnetic (MT) ukuze kutholakale imifantu ebusweni

Ukuhlolwa kwe-Ultrasonic (UT) kokuqina kwangaphakathi

6.4 Ukuhlolwa Kobukhulu

Ukuqinisekiswa ngokumelene nemidwebo evunyiwe

l Ukunaka okukhethekile ekuphakamiseni i-geometry yezingwegwe kanye nezingxenye ezithwala umthwalo obalulekile

7. Imibhalo kanye Nesitifiketi

Imibhalo elandelayo ivame ukuhlinzekwa:

Isitifiketi Sokuhlolwa Kwesigayo (EN 10204 3.1 noma okulinganayo)

l Umbiko wokwakheka kwamakhemikhali

l Imiphumela yokuhlolwa kwemishini

l Irekhodi lokwelashwa kokushisa

Imibiko ye-NDT (uma kudingeka)

Umbiko wokuhlola wobukhulu

Yonke imibhalo ilandelelwa ku-heat and casting batch ehambisanayo.

8. Ububanzi Bokusetshenziswa

Izitsha zensimbi ezikhiqizwe ku-ASTM A27 Grade 70-36 zisetshenziswa kabanzi ku:

l Izitshalo zensimbi kanye nezindawo zokukhiqiza izinto zokwenziwa

l Izinhlelo zokuphatha i-slag

l Ama-workshop e-Metallurgical

l Imisebenzi yokudlulisa izinto zezimboni ezisindayo

Leli banga lifaneleka kakhulu izinhlelo zokusebenza laphoukuguquguquka nokuphepha ngaphansi komthwalo oguqukayozibalulekile.

9. Izinzuzo Zokusebenzisa i-ASTM A27 Grade 70-36 kumaLadle

l Ibhalansi enhle kakhulu phakathi kwamandla kanye nokuguquguquka

l Ingozi encishisiwe yokuphuka okuqhekekile ngaphansi kokushaqeka kokushisa

l Isebenza kahle uma kuqhathaniswa namazinga aphezulu okuqina, aphansi okuguquguquka

l Ukuthembeka okuqinisekisiwe kwezicelo zokusakaza ezisindayo

Ukwamukelwa kabanzi ngabahloli kanye nezinkampani zobunjiniyela

Ulwazi Lokupakisha Nokuthutha

I-NCM Ephakanyisiwe (Ikhodi Yentela):8454100000

Uhlobo Lokupakisha Olusetshenzisiwe:

Isikhidi noma ikesi lokhuni elenziwe ngokwezifiso ukuze lithuthwe olwandle.

Ifilimu yokuvimbela ukugqwala noma i-vapor corrosion esetshenziswa ezindaweni.

Vikela izibambo ngezinsimbi kanye nokhuni ukuze ugweme ukunyakaza ngesikhathi sokuhamba.

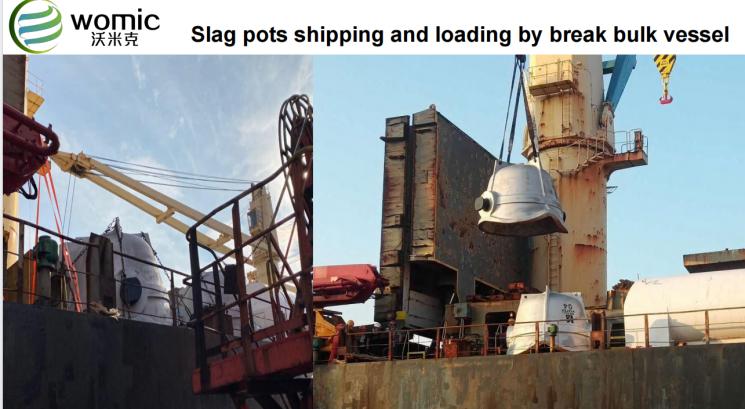

Uhlobo lwezindlela zokuthumela:Isitsha,isitsha esikhulu:

Isitsha Se-Flat Rack– Kukhethwa ukuze kube lula ukulayisha/ukukhulula i-crane.

Isitsha Esivulekile Esiphezulu- Isetshenziswa lapho ukucaciswa okuqondile kuyinkinga.

Isitsha Esiyinqwaba- Ukuze ubukhulu obukhulu bungakwazi ukulayishwa ezitsheni

Udinga ilayisensi yezokuthutha zasendaweni?

Yebo, ngenxa yemvelo enkulu kakhulu yezimbiza,ilayisense yokuthutha ekhethekilengokuvamile kuyadingeka ekulethweni komgwaqo noma kwesitimela. Imibhalo kanye nemidwebo yobuchwepheshe kunganikezwa ukusiza ngezicelo zemvume.

Uma Unemithwalo Ekhethekile Emikhulu Kakhulu, Yiluphi Uhlobo Lwemishini Okufanele Lusetshenziswe Ekuphatheni?

Ama-Crawler Cranesenomthamo owanele wosayizi omncane nesisindo.

Amakhreni ogwiniamabhodwe e-slag anesisindo esingaphezu kwamathani angu-28

Zonke izindawo zokuphakamisa ziklanywe futhi zahlolwa ukuqinisekisa ukuphathwa okuphephile nokuhambisanayo.

10. Isiphetho

I-ASTM A27 Grade 70-36 iyindlela efanelekile futhi engabizi kakhulu yokukhetha izitsha zensimbi ezisetshenziswa ezindaweni zezimboni ezidinga kakhulu. Izakhiwo zayo zemishini, ezihlanganiswe ne-chemistry elawulwayo kanye nokwelashwa okufanele kokushisa, zinikeza ukuthembeka nokusebenza kwesikhathi eside kanye nokuphepha.

Siyaziqhenya nge-izinsizakalo zokwenza ngokwezifiso, imijikelezo yokukhiqiza esheshayo, futhiinethiwekhi yokulethwa komhlaba wonke, ukuqinisekisa ukuthi izidingo zakho ezithile ziyahlangatshezwa ngokunemba nangobungcweti.

Iwebhusayithi: www.womicsteel.com

I-imeyili: sales@womicsteel.com

Ucingo/I-WhatsApp/I-WeChat: Victor: +86-15575100681 noma uJack: +86-18390957568

Isikhathi sokuthunyelwe: Jan-22-2026