Inhloso Yezinto Zokumboza

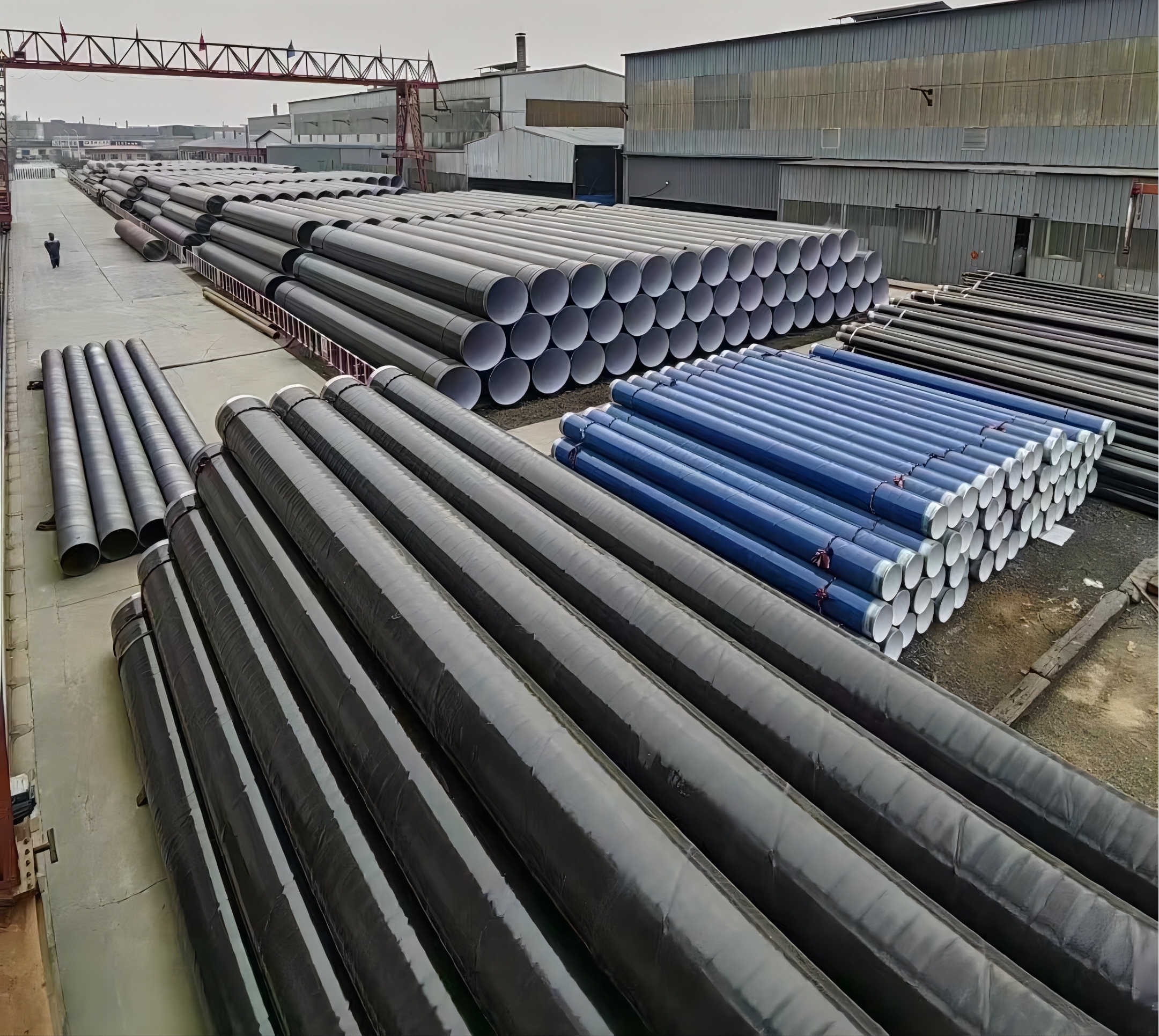

Ukumboza ubuso bangaphandle bamapayipi ensimbi kubalulekile ukuvimbela ukugqwala. Ukugqwala ebusweni bamapayipi ensimbi kungathinta kakhulu ukusebenza kwawo, ikhwalithi, kanye nokubukeka kwawo. Ngakho-ke, inqubo yokumboza inomthelela omkhulu kwikhwalithi iyonke yemikhiqizo yamapayipi ensimbi.

-

Izidingo Zezinto Zokumboza

Ngokwezindinganiso ezibekwe yi-American Petroleum Institute, amapayipi ensimbi kufanele amelane nokugqwala okungenani izinyanga ezintathu. Kodwa-ke, isidingo sesikhathi eside sokulwa nokugqwala sikhulile, kanti abasebenzisi abaningi badinga ukumelana izinyanga ezi-3 kuya kwezi-6 ezimweni zokugcina ngaphandle. Ngaphandle kwesidingo sokuphila isikhathi eside, abasebenzisi balindele ukuthi izembozo zigcine indawo ebushelelezi, ngisho nokusatshalaliswa kwezinto ezilwa nokugqwala ngaphandle kokweqa noma ukuconsa okungase kuthinte ikhwalithi yokubuka.

-

Izinhlobo Zezinto Zokumboza Nezinzuzo Nezinkinga Zazo

Kumanethiwekhi amapayipi angaphansi komhlaba asemadolobheni,amapayipi ensimbizisetshenziswa kakhulu ekuthutheni igesi, uwoyela, amanzi, nokuningi. Ukumbozwa kwala mapayipi kushintshe kusukela ezintweni zendabuko ze-asphalt kuya ezintweni ze-polyethylene resin kanye ne-epoxy resin. Ukusetshenziswa kokumbozwa kwe-polyethylene resin kwaqala ngawo-1980, futhi ngezinhlelo ezahlukene, izingxenye kanye nezinqubo zokumboza kuye kwathuthuka kancane kancane.

3.1 Ukugqoka Nge-Asphalt Kaphethiloli

Ukwembozwa kwe-asphalt ye-petroleum, ungqimba lwendabuko olulwa nokugqwala, luqukethe izendlalelo ze-asphalt ye-petroleum, eziqiniswe ngendwangu ye-fiberglass kanye nefilimu yangaphandle ye-polyvinyl chloride evikelayo. Inikeza ukuvikela amanzi okuhle kakhulu, ukunamathela okuhle ezindaweni ezahlukahlukene, kanye nokusebenza kahle kwezindleko. Kodwa-ke, inezinkinga ezifaka phakathi ukuthambekela ekushintsheni kwezinga lokushisa, ukuqhekeka emazingeni okushisa aphansi, kanye nokuthambekela ekugugeni nasekuqhekekeni, ikakhulukazi ezimweni zenhlabathi enamatshe, okudinga izinyathelo ezengeziwe zokuvikela kanye nezindleko ezengeziwe.

3.2 Ukugqoka i-Coal Tar Epoxy

I-epoxy ye-coal tar, eyenziwe nge-epoxy resin kanye ne-asphalt ye-coal tar, ikhombisa ukumelana okuhle kwamanzi namakhemikhali, ukumelana nokugqwala, ukunamathela okuhle, amandla okusebenza, kanye nezakhiwo zokuvikela. Kodwa-ke, idinga isikhathi eside sokuqina ngemva kokusetshenziswa, okwenza kube lula ukuthola imiphumela emibi evela ezimweni zezulu phakathi nalesi sikhathi. Ngaphezu kwalokho, izakhi ezahlukahlukene ezisetshenziswa kulolu hlelo lokumboza zidinga isitoreji esikhethekile, okukhulisa izindleko.

3.3 Isimbozo Sempuphu Ye-Epoxy

I-epoxy powder coating, eyethulwa ngawo-1960, ihilela ukufafaza i-powder ngogesi ezindaweni zamapayipi alungisiwe futhi ashisiwe, okwenza ungqimba oluqinile olulwa nokugqwala. Izinzuzo zayo zifaka phakathi izinga lokushisa elibanzi (-60°C kuya ku-100°C), ukunamathela okuqinile, ukumelana okuhle nokuqhekeka kwe-cathodic, umthelela, ukuguquguquka, kanye nomonakalo we-weld. Kodwa-ke, ifilimu yayo encane iyenza ibe sengozini yokulimala futhi idinga amasu okukhiqiza ayinkimbinkimbi kanye nemishini, okuletha izinselele ekusetshenzisweni kwensimu. Nakuba iphumelela kakhulu ezicini eziningi, ayilingani ne-polyethylene maqondana nokumelana nokushisa kanye nokuvikelwa kokugqwala okuphelele.

3.4 I-Polyethylene Ukugqoka Okungagqwali

I-Polyethylene inikeza ukumelana okuhle kakhulu nokushayisana kanye nokuqina okuphezulu kanye nobubanzi bokushisa obubanzi. Isetshenziswa kakhulu ezindaweni ezibandayo njengeRussia neNtshonalanga Yurophu kumapayipi ngenxa yokuguquguquka kwayo okuphezulu kanye nokumelana nokushayisana, ikakhulukazi emazingeni okushisa aphansi. Kodwa-ke, kusenezinselelo ekusetshenzisweni kwayo kumapayipi amakhulu, lapho kungase kube nokuqhekeka kokucindezeleka, futhi ukungena kwamanzi kungaholela ekugqwaleni ngaphansi kwengubo, okudinga ucwaningo olwengeziwe kanye nokuthuthukiswa kwezindlela zokwakha kanye nokusetshenziswa.

3.5 Isimbozo Esinzima Sokulwa Nokugqwala

Izembozo ezisindayo zokulwa nokugqwala zinikeza ukumelana nokugqwala okuthuthukisiwe kakhulu uma kuqhathaniswa nezembozo ezijwayelekile. Zibonisa ukusebenza kahle kwesikhathi eside ngisho nasezimweni ezinzima, isikhathi sokuphila esingaphezu kweminyaka eyi-10 kuya kweyi-15 ezindaweni zamakhemikhali, zasolwandle, kanye nezinyibilikisi, kanye neminyaka engaphezu kwemi-5 ezimweni ze-acidic, alkaline, noma ezimanzi. Lezi zembozo ngokuvamile zinobukhulu befilimu eyomile obusukela ku-200μm kuya ku-2000μm, okuqinisekisa ukuvikelwa okuphezulu nokuqina. Zisetshenziswa kabanzi ezakhiweni zasolwandle, imishini yamakhemikhali, amathangi okugcina izinto, kanye namapayipi.

-

Izinkinga Ezivamile Ngezinto Zokumboza

Izinkinga ezivamile ngezingubo zifaka phakathi ukusetshenziswa okungalingani, ukuconsa kwezinto ezilwa nokugqwala, kanye nokwakheka kwamabhamuza.

(1) Ukwemboza okungalingani: Ukusatshalaliswa okungalingani kwezinto ezilwa nokugqwala ebusweni bepayipi kuholela ezindaweni ezinobukhulu obukhulu bekwemboza, okuholela ekuchithekeni, kuyilapho izindawo ezincane noma ezingambozwanga zinciphisa ikhono lepayipi lokulwa nokugqwala.

(2) Ukuconsa kwama-anti-corrosive agents: Lesi simo, lapho ama-anti-corrosive agents eqina khona njengamaconsi ebusweni bepayipi, sithinta ubuhle ngenkathi singathinti ngqo ukumelana nokugqwala.

(3) Ukwakheka kwamabhamuza: Umoya ovaleleke ngaphakathi kwe-ejenti elwa nokugqwala ngesikhathi sokusetshenziswa udala amabhamuza ebusweni bepayipi, okuthinta kokubili ukubukeka nokusebenza kahle kokumboza.

-

Ukuhlaziywa Kwezinkinga Zekhwalithi Yokumboza

Yonke inkinga ivela ngezizathu ezahlukahlukene, ibangelwa izici ezahlukahlukene; futhi inqwaba yepayipi lensimbi egqanyiswe yikhwalithi yenkinga nayo ingaba inhlanganisela yezinhlobo eziningana. Izimbangela zokugqoka okungalingani zingahlukaniswa cishe zibe izinhlobo ezimbili, enye iyinto engalingani ebangelwa ukufafaza ngemva kokuba ipayipi lensimbi lingene ebhokisini lokumboza; eyesibili iyinto engalingani ebangelwa ukungafafazi.

Isizathu sento yokuqala kulula ukuyibona, imishini yokumboza lapho ipayipi lensimbi lingena ebhokisini lokumboza ku-360 ° lizungeze izibhamu eziyi-6 (umugqa wekheshi unezibhamu eziyi-12) zokufutha. Uma isibhamu ngasinye esifuthwe ngaphandle kobukhulu bokugeleza sihlukile, khona-ke kuzoholela ekusakazweni okungalingani kwe-ejenti yokulwa nokugqwala ezindaweni ezahlukene zepayipi lensimbi.

Isizathu sesibili ukuthi kunezinye izizathu zesenzakalo sokungalingani kokumboza ngaphandle kwesici sokufafaza. Kunezinhlobo eziningi zezici, njengokugqwala okungenayo kwepayipi lensimbi, ubulukhuni, ukuze ukumboza kube nzima ukusatshalaliswa ngokulinganayo; ubuso bepayipi lensimbi bunesilinganiso sokucindezela kwamanzi esisele ngemuva lapho i-emulsion, kulokhu ngenxa yokumboza ngenxa yokuxhumana ne-emulsion, ukuze isivikelo sibe nzima ukusinamathisela ebusweni bepayipi lensimbi, ukuze kungabikho ukumboza izingxenye zepayipi lensimbi le-emulsion, okuholela ekutheni ukumboza kwepayipi lensimbi lonke kungafani.

(1) Isizathu sokulenga kwe-ejenti elwa nokugqwala. Ingxenye enqamulelayo yepayipi lensimbi iyindilinga, njalo lapho i-ejenti elwa nokugqwala ifuthwa ebusweni bepayipi lensimbi, i-ejenti elwa nokugqwala engxenyeni engenhla kanye nonqenqema izogeleza iye engxenyeni engezansi ngenxa yesici sokudonsa phansi, okuzokwakha isimo sokulenga phansi. Into enhle ukuthi kunemishini yehhavini emgqeni wokukhiqiza ungqimba wefektri yepayipi lensimbi, engafudumeza futhi iqinise i-ejenti elwa nokugqwala efuthwe ebusweni bepayipi lensimbi ngesikhathi futhi inciphise ukugeleza kwe-ejenti elwa nokugqwala. Kodwa-ke, uma i-viscosity ye-ejenti elwa nokugqwala ingekho phezulu; akukho ukushisa ngesikhathi ngemva kokufutha; noma izinga lokushisa lokushisa lingekho phezulu; umlomo awukho esimweni esihle sokusebenza, njll. kuzoholela ekulengeni kwe-ejenti elwa nokugqwala.

(2) Izimbangela zokuqhuma kwegwebu okulwa nokugqwala. Ngenxa yendawo yokusebenza yomswakama womoya, ukuhlakazeka kopende kukhulu kakhulu, ukwehla kwezinga lokushisa kwenqubo yokuhlakazeka kuzobangela ukuqhuma kokugcina. Indawo yomswakama womoya, izimo zokushisa eziphansi, izithasiselo ezifuthwayo ziphuma kulezo ezihlakazekile zibe amaconsi amancane, kuzoholela ekwehleni kwezinga lokushisa. Amanzi emoyeni anomswakama ophezulu ngemva kokwehla kwezinga lokushisa azohlangana abe amaconsi amanzi amancane axutshwe nesithasiselo, futhi ekugcineni angene ngaphakathi kwesithasiselo, okuholela ekwehleni kokugcina.

Isikhathi sokuthunyelwe: Disemba 15-2023