Insimbi engagqwali isifinyezo sensimbi engagqwali engagqwali engagqwali, umoya, umusi, amanzi kanye nezinye izinto ezibuthakathaka ezigqwali noma insimbi engagqwali yaziwa ngokuthi insimbi engagqwali; futhi izomelana nezinto ezigqwali zamakhemikhali (ama-asidi, ama-alkali, usawoti, kanye nezinye izinto ezifakwa ngamakhemikhali) ukugqwala kwensimbi kubizwa ngokuthi insimbi engagqwali engagqwali.

Insimbi engagqwali ibhekisela emoyeni, umusi, amanzi kanye nezinye izinto ezibuthakathaka ezibolayo kanye nama-asidi, ama-alkali, usawoti kanye nezinye izinto ezibolayo zamakhemikhali ezibangelwa ukugqwala kwensimbi, okwaziwa nangokuthi insimbi engagqwali engagqwali engagqwali. Empeleni, ngokuvamile insimbi engagqwali engagqwali ebizwa ngokuthi insimbi engagqwali, kanye nensimbi engagqwali engagqwali ebizwa ngokuthi insimbi engagqwali. Ngenxa yomehluko ekwakhiweni kwamakhemikhali kwalokhu okubili, okokuqala akusho ukuthi kumelana nokugqwala kwamakhemikhali, kuyilapho lokhu kwamuva ngokuvamile kungelasici. Ukumelana nokugqwala kwensimbi engagqwali kuncike ezintweni ezihlanganisiwe eziqukethwe ensimbini.

Ukuhlukaniswa Okuvamile

Ngokusho kwenhlangano ye-metallurgical

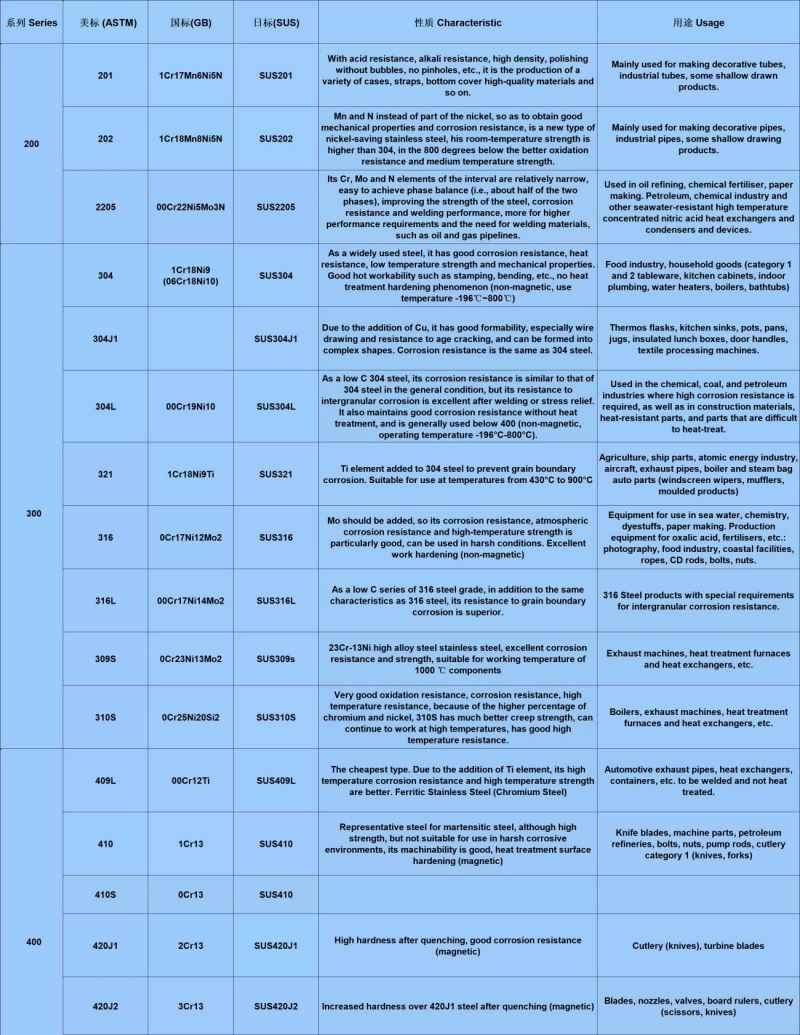

Ngokuvamile, ngokusho kwenhlangano ye-metallurgical, izinsimbi ezivamile ezingagqwali zihlukaniswe ngezigaba ezintathu: izinsimbi ezingagqwali ze-austenitic, izinsimbi ezingagqwali ze-ferritic kanye nezinsimbi ezingagqwali ze-martensitic. Ngokusekelwe ekuhleleni okuyisisekelo kwe-metallurgical kwalezi zigaba ezintathu, izinsimbi ezimbili, izinsimbi ezingagqwali eziqinisa imvula kanye nezinsimbi ze-alloy ephezulu eziqukethe insimbi engaphansi kuka-50% zitholakala ngezidingo nezinjongo ezithile.

1. Insimbi engagqwali yase-Austenitic

Isakhiwo sekristalu le-cubic eliphakathi nendawo kuya kobuso benhlangano ye-austenitic (isigaba se-CY) silawulwa yi-non-magnetic, ikakhulukazi ngokusebenzisa ukusebenza okubandayo ukuze kuqiniswe (futhi kungaholela ezingeni elithile le-magnetism). I-American Iron and Steel Institute ihlanganisa uchungechunge lwamalebula ezinombolo angu-200 no-300, njenge-304.

2. Insimbi engagqwali ye-Ferritic

Isakhiwo sekristalu le-cubic esigxile emzimbeni se-ferrite (isigaba) sinamandla, sinobuthi, ngokuvamile asinakwenziwa lukhuni ngokwelashwa kokushisa, kodwa ukusebenza okubandayo kungenza insimbi engagqwali iqine kancane. I-American Iron and Steel Institute iya ku-430 kanye no-446 ngelebula.

3. Insimbi engagqwali ye-Martensitic

I-matrix iyi-martensitic organization (i-cubic noma i-cubic egxile emzimbeni), i-magnetic, ngokwelashwa kokushisa ingalungisa izakhiwo zayo zensimbi engagqwali. I-American Iron and Steel Institute ibhalwe ku-410, 420, kanye nezibalo ezingu-440. I-Martensite ine-austenitic organization emazingeni okushisa aphezulu, engaguqulwa ibe yi-martensite (okungukuthi iqiniswe) uma ipholiswa ekushiseni kwegumbi ngesivinini esifanele.

4. Insimbi engagqwali yohlobo lwe-Austenitic uhlobo lwe-ferrite (duplex)

I-matrix ine-austenitic kanye ne-ferrite two-phase organization, lapho okuqukethwe kwe-lesser phase matrix ngokuvamile kungaphezu kuka-15%, okune-magnetic, kungaqiniswa ngokusebenza okubandayo kwensimbi engagqwali, i-329 iyinsimbi engagqwali ejwayelekile ye-duplex. Uma iqhathaniswa nensimbi engagqwali ye-austenitic, insimbi ye-duplex enamandla aphezulu, ukumelana nokugqwala kwe-intergranular kanye nokugqwala kokucindezeleka kwe-chloride kanye nokugqwala kwe-pitting kuthuthukiswa kakhulu.

5. Insimbi engagqwali eqinisa imvula

I-matrix iyi-austenitic noma i-martensitic, futhi ingaqiniswa ngokwelashwa kokuqina kwemvula ukuze iqine insimbi engagqwali. I-American Iron and Steel Institute ihlanganisa uchungechunge lwamalebula edijithali angu-600, njenge-630, okungukuthi, i-17-4PH.

Ngokuvamile, ngaphezu kwama-alloy, ukumelana nokugqwala kwensimbi engagqwali ye-austenitic kuphakeme, endaweni engagqwali kakhulu, ungasebenzisa insimbi engagqwali ye-ferritic, ezindaweni ezingagqwali kahle, uma impahla idingeka ukuze ibe namandla aphezulu noma ubulukhuni obuphezulu, ungasebenzisa insimbi engagqwali ye-martensitic kanye nensimbi engagqwali eqinisa imvula.

Izici kanye nokusetshenziswa

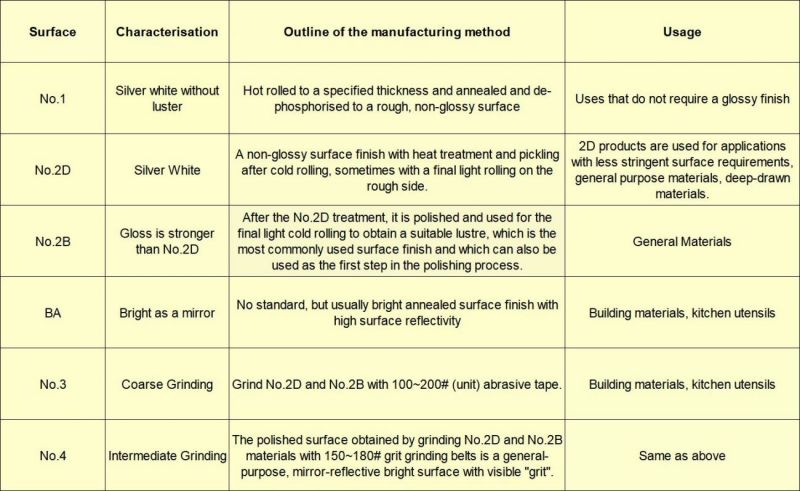

Inqubo yobuso

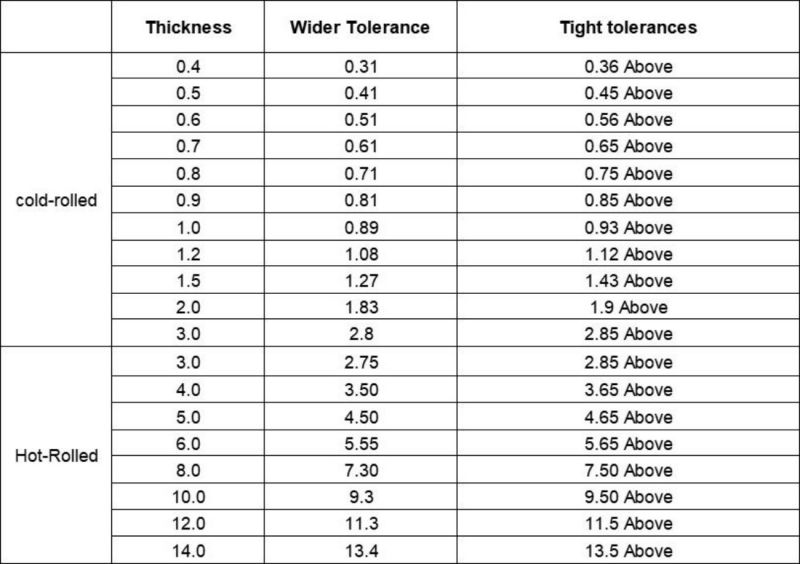

Ukwahlukaniswa kobukhulu

1. Ngenxa yokuthi imishini yokugaya insimbi isenqubo yokugoqa, imiqulu ishiswa ukuguquguquka okuncane, okuholela ekugoqeni ukuphambuka kobukhulu bepuleti, ngokuvamile obukhulu phakathi kwezinhlangothi ezimbili zobukhulu obuncane. Ekulinganiseni ukujiya kwepuleti, imithethonqubo yesimo sepuleti kufanele ilinganiswe phakathi kwekhanda lepuleti.

2. Isizathu sokubekezelelana sisekelwe emakethe kanye nesidingo samakhasimende, ngokuvamile sihlukaniswe ngokubekezelelana okukhulu nokuncane.

V. Izidingo zokukhiqiza, ukuhlolwa

1. Ipuleti lepayipi

① amalunga e-tube plate butt ahlanganisiwe ukuze kuhlolwe imisebe engu-100% noma i-UT, izinga elifanelekile: RT: Ⅱ UT: izinga Ⅰ;

② Ngaphezu kwensimbi engagqwali, ukwelashwa kokunciphisa ukucindezeleka kwepayipi elihlanganisiwe;

③ ukuphambuka kobubanzi bebhuloho lembobo le-tube plate: ngokwefomula yokubala ububanzi bebhuloho lembobo: B = (S - d) - D1

Ububanzi obuncane bebhuloho lembobo: B = 1/2 (S - d) + C;

2. Ukwelashwa kokushisa kwebhokisi leshubhu:

Insimbi yekhabhoni, insimbi ephansi ye-alloy eshiselwe nge-split-range partition yebhokisi lepayipi, kanye nebhokisi lepayipi lezikhala eziseceleni ezingaphezu kwe-1/3 yobubanzi bangaphakathi bebhokisi lepayipi lesilinda, ekusetshenzisweni kwe-welding yokwelapha ukushisa okudambisa ukucindezeleka, i-flange kanye nokuvala indawo yokuhlukanisa kufanele kucutshungulwe ngemuva kokwelashwa kokushisa.

3. Ukuhlolwa kokucindezela

Uma ingcindezi yokuklama inqubo yegobolondo iphansi kunengcindezi yenqubo yepayipi, ukuze kuhlolwe ikhwalithi yepayipi yokushintshanisa ukushisa kanye nokuxhumeka kwepuleti lepayipi

① Ukucindezela kohlelo lwe-Shell ukwandisa ingcindezi yokuhlola ngohlelo lwepayipi kuhambisana nokuhlolwa kwe-hydraulic, ukuhlola ukuthi ngabe ukuvuza kwamajoyinti epayipi kuyavuza yini. (Kodwa-ke, kuyadingeka ukuqinisekisa ukuthi ukucindezeleka kwefilimu okuyinhloko kwegobolondo ngesikhathi sokuhlolwa kwe-hydraulic kungu-≤0.9ReLΦ)

② Uma indlela engenhla ingafaneleki, igobolondo lingahlolwa nge-hydrostatic ngokuya ngengcindezi yokuqala ngemuva kokudlula, bese kuba yigobolondo lokuhlolwa kokuvuza kwe-ammonia noma ukuhlolwa kokuvuza kwe-halogen.

Hlobo luni lwensimbi engagqwali okungelula ukugqwala?

Kunezici ezintathu eziyinhloko ezithinta ukugqwala kwensimbi engagqwali:

1. Okuqukethwe kwezinto ezixubayo. Ngokuvamile, okuqukethwe kwe-chromium ensimbini engu-10.5% akulula ukugqwala. Uma okuqukethwe okuphezulu kwe-chromium kanye nokumelana nokugqwala kwe-nickel kungcono, njengokuqukethwe kwe-nickel okungu-304 okungu-85 ~ 10%, okuqukethwe kwe-chromium okungu-18% ~ 20%, insimbi engagqwali enjalo ngokuvamile ayigqwali.

2. Inqubo yokuncibilikisa yomkhiqizi izothinta nokumelana nokugqwala kwensimbi engagqwali. Ubuchwepheshe bokuncibilikisa bulungile, imishini ethuthukisiwe, ubuchwepheshe obuthuthukisiwe, isitshalo esikhulu sensimbi engagqwali kokubili ekulawuleni izinto zokuxuba, ukususwa kokungcola, ukulawulwa kokushisa kokupholisa kwe-billet kungaqinisekiswa, ngakho ikhwalithi yomkhiqizo izinzile futhi ithembekile, ikhwalithi enhle yangaphakathi, akulula ukuyigqwala. Ngokuphambene nalokho, eminye imishini yesitshalo sensimbi encane emuva, ubuchwepheshe emuva, inqubo yokuncibilikisa, ukungcola akukwazi ukususwa, ukukhiqizwa kwemikhiqizo kuzogqwala ngokungenakugwenywa.

3. Indawo engaphandle. Indawo eyomile nengena umoya akulula ukuyigqwala, kuyilapho umswakama womoya, isimo sezulu esinemvula esiqhubekayo, noma umoya oqukethe i-asidi kanye ne-alkalinity yendawo kulula ukuyigqwala. Insimbi engagqwali, uma indawo ezungezile imbi kakhulu nayo iyagqwala.

Izindawo zokugqwala zensimbi engagqwali zingabhekana kanjani nazo?

1. Indlela yamakhemikhali

Nge-pickling paste noma i-spray ukusiza izingxenye zayo ezigqwalile ukuthi ziphinde zivuselele ukwakheka kwefilimu ye-chromium oxide ukuze kubuyiselwe ukumelana kwayo nokugqwala, ngemva kwe-pickling, ukuze kususwe zonke izinto ezingcolisayo kanye nezinsalela ze-asidi, kubaluleke kakhulu ukuhlanza kahle ngamanzi. Ngemva kokuthi konke sekucutshungulwe futhi kupholishwe kabusha ngemishini yokupholisha, kungavalwa nge-wax yokupholisha. Ukuze uthole izindawo ezincane zokugqwala endaweni, ingxube kaphethiloli engu-1:1 ingasetshenziswa futhi, ingxube kawoyela nendwangu ehlanzekile yokususa izindawo zokugqwala ingasetshenziswa.

2. Izindlela zemishini

Ukuhlanza ngesanti, ukuhlanza ngengilazi noma ngezinhlayiya ze-ceramic, ukuqhumisa, ukubhulasha nokupholisha. Izindlela zemishini zinamandla okususa ukungcola okubangelwa izinto ezisusiwe ngaphambilini, izinto zokupholisha noma izinto eziqediwe. Zonke izinhlobo zokungcola, ikakhulukazi izinhlayiya zensimbi zakwamanye amazwe, zingaba umthombo wokugqwala, ikakhulukazi ezindaweni ezinomswakama. Ngakho-ke, izindawo ezihlanzwe ngomshini kufanele zihlanzwe ngokusemthethweni ngaphansi kwezimo ezomile. Ukusetshenziswa kwezindlela zemishini kuhlanza kuphela ubuso bayo futhi akushintshi ukumelana nokugqwala kwezinto ngokwazo. Ngakho-ke, kunconywa ukuthi uphinde upholise ubuso ngemishini yokupholisha bese uvala nge-wax yokupholisha ngemva kokuhlanza ngomshini.

Izinsimbi ezisetshenziswa kakhulu ngamamaki ensimbi engagqwali kanye nezakhiwo

Insimbi engagqwali engu-1.304. Ingenye yezinsimbi ezingagqwali ze-austenitic ezinokusetshenziswa okukhulu nokusetshenziswa okubanzi, ezifanele ukukhiqiza izingxenye zokubumba ezidonswe ngokujulile kanye namapayipi e-asidi, izitsha, izingxenye zesakhiwo, izinhlobo ezahlukene zezinsimbi, njll. Ingakhiqiza futhi imishini nezingxenye ezingezona ezisebenzisa ugesi, ezinokushisa okuphansi.

Insimbi engagqwali engu-2.304L. Ukuze kuxazululwe imvula ye-Cr23C6 ebangelwa insimbi engagqwali engu-304 kwezinye izimo, kukhona ukuthambekela okukhulu kokugqwala kwe-intergranular kanye nokuthuthukiswa kwensimbi engagqwali ye-austenitic enekhabhoni ephansi kakhulu, isimo sayo esibucayi sokumelana nokugqwala kwe-intergranular singcono kakhulu kunensimbi engagqwali engu-304. Ngaphezu kwamandla aphansi kancane, ezinye izakhiwo ezinensimbi engagqwali engu-321, ezisetshenziswa kakhulu emishinini nasezintweni ezingagqwali azikwazi ukushintshwa, zingasetshenziswa ekwenzeni izinhlobo ezahlukene zomzimba wezinsimbi.

Insimbi engagqwali engu-3.304H. Igatsha langaphakathi lensimbi engagqwali engu-304, ingxenye yesisindo sekhabhoni ingu-0.04% ~ 0.10%, ukusebenza kwezinga lokushisa eliphezulu kungcono kunensimbi engagqwali engu-304.

Insimbi engagqwali engu-4.316. Ensimbini engu-10Cr18Ni12 esekelwe ekufakweni kwe-molybdenum, ukuze insimbi ibe nokumelana okuhle nokunciphisa imidiya kanye nokumelana nokugqwala kwemigodi. Emanzini olwandle nakwezinye imidiya, ukumelana nokugqwala kungcono kunensimbi engagqwali engu-304, esetshenziswa kakhulu ekufakeni imigodi ezintweni ezingagqwali.

Insimbi engagqwali engu-5.316L. Insimbi yekhabhoni ephansi kakhulu, enokumelana okuhle nokugqwala okuzwelayo phakathi kwe-granular, ifaneleka ekwakhiweni kobukhulu obukhulu bezingxenye ezihlanganisiwe nemishini, njengemishini ye-petrochemical ezintweni ezingagqwali.

Insimbi engagqwali engu-6.316H. Igatsha langaphakathi lensimbi engagqwali engu-316, ingxenye yesisindo sekhabhoni engu-0.04%-0.10%, ukusebenza kwezinga lokushisa eliphezulu kungcono kunensimbi engagqwali engu-316.

Insimbi engagqwali engu-7.317. Ukumelana nokugqwala kanye nokumelana nokuqhekeka kwe-pitting kungcono kunensimbi engagqwali engu-316L, esetshenziswa ekwenziweni kwemishini evikela ukugqwala nge-petrochemical kanye ne-organic acid.

Insimbi engagqwali engu-8.321. Insimbi engagqwali ye-austenitic eqiniswe yi-titanium, enezela i-titanium ukuthuthukisa ukumelana nokugqwala phakathi kwe-granular, futhi inezakhiwo ezinhle zomshini zokushisa okuphezulu, ingathathelwa indawo yinsimbi engagqwali ye-austenitic e-carbon ephansi kakhulu. Ngaphezu kokumelana nokugqwala okushisa okuphezulu noma kwe-hydrogen kanye nezinye izikhathi ezikhethekile, isimo esijwayelekile asikhuthazwa.

9.347 insimbi engagqwali. Insimbi engagqwali ye-austenitic eqiniswe yi-niobium, i-niobium engeziwe ukuthuthukisa ukumelana nokugqwala kwe-intergranular, ukumelana nokugqwala ku-asidi, i-alkali, usawoti kanye nezinye izinto ezigqwali ngensimbi engagqwali engu-321, ukusebenza kahle kokushisela, ingasetshenziswa njengezinto ezimelana nokugqwala kanye nensimbi engamelana nokushisa esetshenziswa kakhulu kumandla okushisa, amasimu e-petrochemical, njengokukhiqizwa kweziqukathi, amapayipi, ama-heat exchanger, imiphini, izitofu zezimboni epayipini lesithando kanye ne-thermometer yepayipi lesithando nokunye.

Insimbi engagqwali engu-10.904L. Insimbi engagqwali ye-austenitic ephelele kakhulu, insimbi engagqwali ye-austenitic esungulwe yiFinland Otto Kemp, ingxenye yayo yesisindo se-nickel engu-24% kuya ku-26%, ingxenye yesisindo se-carbon engaphansi kuka-0.02%, ukumelana okuhle kakhulu kokugqwala, kuma-asidi angenayo i-oxidizing njenge-sulfuric, i-acetic, i-formic kanye ne-phosphoric acid inokumelana okuhle kakhulu kokugqwala, futhi ngesikhathi esifanayo inokumelana okuhle kokugqwala okuqhekekile kanye nokumelana nezakhiwo zokugqwala kokucindezeleka. Ifanele amazinga ahlukahlukene e-sulfuric acid ngaphansi kuka-70℃, futhi inokumelana okuhle kokugqwala ne-acetic acid kanye ne-acid exubile ye-formic acid kanye ne-acetic acid yanoma yikuphi ukugqwala nanoma yikuphi ukushisa ngaphansi kwengcindezi evamile. I-ASMESB-625 yokuqala iyibeka kuma-alloy asekelwe ku-nickel, kanti indinganiso entsha iyibeka ensimbini engagqwali. I-China kuphela i-015Cr19Ni26Mo5Cu2 steel elinganiselwa ku-015Cr19Ni26Mo5Cu2, abakhiqizi bezinsimbi abambalwa baseYurophu bezinto ezibalulekile besebenzisa insimbi engagqwali engu-904L, njenge-E + H's mass flowmeter measuring tube isetshenziswa insimbi engagqwali engu-904L, i-Rolex watch case nayo isetshenziswa insimbi engagqwali engu-904L.

Insimbi engagqwali engu-11.440C. Insimbi engagqwali ye-Martensitic, insimbi engagqwali eqina, insimbi engagqwali enobunzima obukhulu kakhulu, ubulukhuni HRC57. Isetshenziswa kakhulu ekukhiqizeni ama-nozzles, ama-bearings, ama-valve, ama-valve spools, izihlalo zama-valve, imikhono, iziqu zama-valve, njll.

Insimbi engagqwali engu-12.17-4PH. Insimbi engagqwali eqinisa imvula ye-martensitic, ubulukhuni be-HRC44, enamandla aphezulu, ubulukhuni kanye nokumelana nokugqwala, ayikwazi ukusetshenziselwa amazinga okushisa aphezulu kuno-300 ℃. Inokumelana okuhle kokugqwala kokubili kuma-acid noma usawoti womoya kanye nowokuncibilikisa, futhi ukumelana kwayo nokugqwala kufana nokwensimbi engagqwali engu-304 kanye nensimbi engagqwali engu-430, esetshenziswa ekwenziweni kwamapulatifomu asogwini, ama-turbine blades, ama-spool, izihlalo, imikhono kanye neziqu zama-valve.

Emsebenzini wokwenza izinsimbi, kuhlanganiswe nezinkinga ezivamile kanye nezindleko, i-oda lokukhetha insimbi engagqwali ye-austenitic ejwayelekile yi-304-304L-316-316L-317-321-347-904L insimbi engagqwali, lapho i-317 ingasetshenziswa kakhulu, i-321 ayinconywa, i-347 isetshenziselwa ukugqwala okushisa okuphezulu, i-904L iyinto ezenzakalelayo yezingxenye ezithile zabakhiqizi ngabanye, umklamo ngeke uthathe isinyathelo sokukhetha i-904L.

Ekukhetheni umklamo wezinsimbi zomculo, ngokuvamile kuzoba nezinto zokufakelwa kanye nezinto zokufakelwa ipayipi ngezikhathi ezahlukene, ikakhulukazi ezimweni zokushisa okuphezulu, kumelwe sinake ngokukhethekile ukukhethwa kwezinto zokufakelwa ukuze kuhlangatshezwane nemishini yenqubo noma izinga lokushisa lomklamo wepayipi kanye nengcindezi yomklamo, njengepayipi lensimbi le-chrome molybdenum lokushisa eliphezulu, kuyilapho izinsimbi zomculo zikhetha insimbi engagqwali, khona-ke kungenzeka kakhulu ukuthi kube yinkinga, kumele uye kudokotela ukuze uhlole izinga lokushisa lezinto ezibonakalayo kanye nesilinganiso sokucindezela.

Ekukhetheni ukwakheka kwezinsimbi, kuvame ukuhlangana nezinhlelo ezahlukahlukene, uchungechunge, amamaki ensimbi engagqwali, ukukhethwa kufanele kusekelwe kumidiya yenqubo ethile, izinga lokushisa, ingcindezi, izingxenye ezicindezelekile, ukugqwala kanye nezindleko kanye neminye imibono.

Isikhathi sokuthunyelwe: Okthoba-11-2023