1. Okujwayelekile: SANS 719

2. Ibanga: C

3. Uhlobo: Ukumelana Nogesi Okushiselwe (ERW)

4. Ububanzi Bosayizi:

- Ububanzi bangaphandle: 10mm kuya ku-610mm

- Ubukhulu Bodonga: 1.6mm kuya ku-12.7mm

5. Ubude: amamitha ayi-6, noma njengoba kudingeka

6. Iziphetho: Isiphetho esilula, isiphetho esigobile

7. Ukwelashwa Komphezulu:

- Omnyama (ozimibalabala)

- Kunamafutha

- I-Galvanised

- Kupendwe

8. Izicelo: Amanzi, indle, ukuthuthwa okuvamile koketshezi

9. Ukwakheka Kwamakhemikhali:

- Ikhabhoni (C): 0.28% ubuningi

- I-Manganese (Mn): 1.25% ubuningi

- I-Phosphorus (P): 0.040% ubuningi

- I-Sulfur (S): 0.020% ubuningi

- I-Silcon (Si): 0.04% ubuningi. Noma 0.135% kuya ku-0.25%

10. Izakhiwo Zemishini:

- Amandla Okudonsa: 414MPa min

- Amandla Okukhiqiza: 290 MPa min

- Ukwelulwa: 9266 kuhlukaniswe ngenani lezinombolo le-UTS yangempela

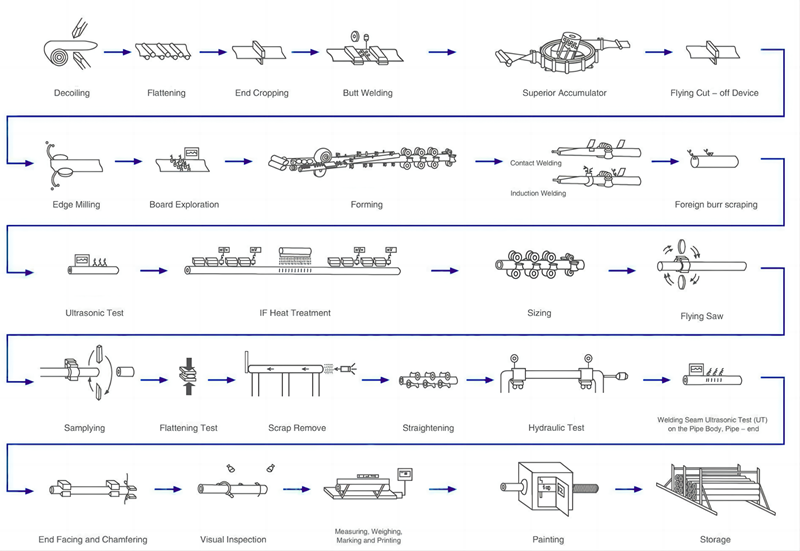

11. Inqubo Yokukhiqiza:

- Ipayipi lenziwa kusetshenziswa inqubo eyenziwe ngokushisa okubandayo kanye nenqubo yokufakelwa kwe-induction ephindaphindwayo (i-HFIW).

- Umcu wenziwa ube yisimo se-tubular bese uhlanganiswa ngobude kusetshenziswa ukushisela kokungeniswa okuvama kakhulu.

12. Ukuhlolwa Nokuhlolwa:

- Ukuhlaziywa kwamakhemikhali kwezinto zokusetshenziswa

- Ukuhlolwa kokudonsa okuguquguqukayo ukuqinisekisa ukuthi izakhiwo zemishini ziyahambisana nemininingwane

- Ukuhlolwa kokuthamba ukuqinisekisa ikhono lepayipi lokubekezelela ukuguquguquka

- Ukuhlolwa kokugoba kwezimpande (ukushintshwa kokuhlanganiswa kukagesi) ukuqinisekisa ukuguquguquka nobuqotho bepayipi

- Ukuhlolwa kwe-hydrostatic ukuqinisekisa ukuqina kwepayipi elivuzayo

13. Ukuhlolwa Okungonakalisi (NDT):

- Ukuhlolwa kwe-Ultrasonic (UT)

- Ukuhlolwa kwamanje kwe-Eddy (ET)

14. Isitifiketi:

- Isitifiketi sokuhlolwa kwe-Mill (MTC) ngokusho kwe-EN 10204/3.1

- Ukuhlolwa komuntu wesithathu (ongakukhetha)

15. Ukupakisha:

- Ngamaqoqo

- Izigqoko zepulasitiki kuzo zombili izinhlangothi

- Iphepha elingangenwa manzi noma isembozo seshidi lensimbi

- Ukumaka: njengoba kudingeka (kufaka phakathi uMenzi, ibanga, usayizi, okujwayelekile, inombolo yokushisa, inombolo yeLothi njll.)

16. Isimo Sokulethwa:

- Njengoba igoqiwe

- Okujwayelekile

- Okugoqiwe okuvamile

17. Ukumaka:

- Ipayipi ngalinye kufanele libhalwe ngendlela efundekayo ngolwazi olulandelayo:

- Igama noma uphawu lokuhweba lomkhiqizi

- Ibanga C le-SANS 719

- Usayizi (ububanzi bangaphandle kanye nobukhulu bodonga)

- Inombolo yokushisa noma inombolo yeqoqo

- Usuku lokwenziwa

- Imininingwane yesitifiketi sokuhlola nokuhlola

18. Izidingo Ezikhethekile:

- Amapayipi angahlinzekwa ngezingubo ezikhethekile noma ama-linings ukuze kusetshenziswe okuthile (isb., i-epoxy coating yokumelana nokugqwala).

19. Ukuhlolwa Okwengeziwe (Uma Kudingeka):

- Ukuhlolwa komthelela we-Charpy V-notch

- Ukuhlolwa kobulukhuni

- Ukuhlolwa kwesakhiwo esikhulu

- Ukuhlolwa kwesakhiwo esincane

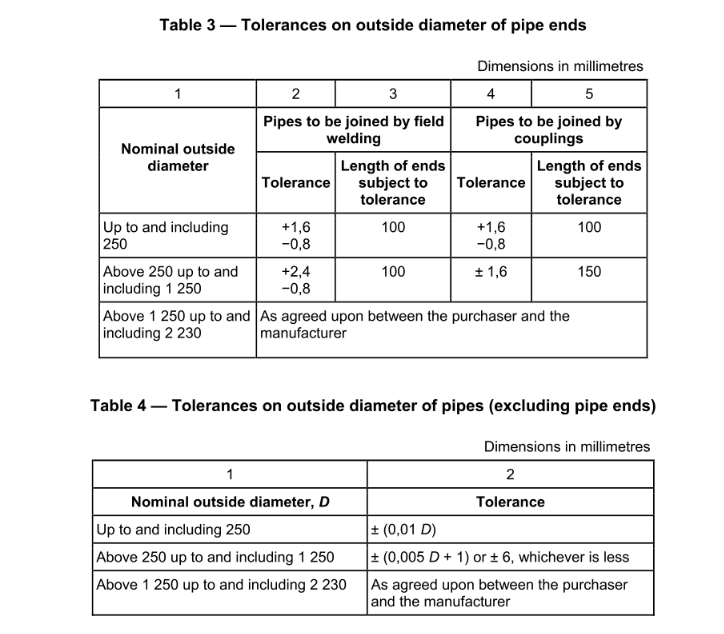

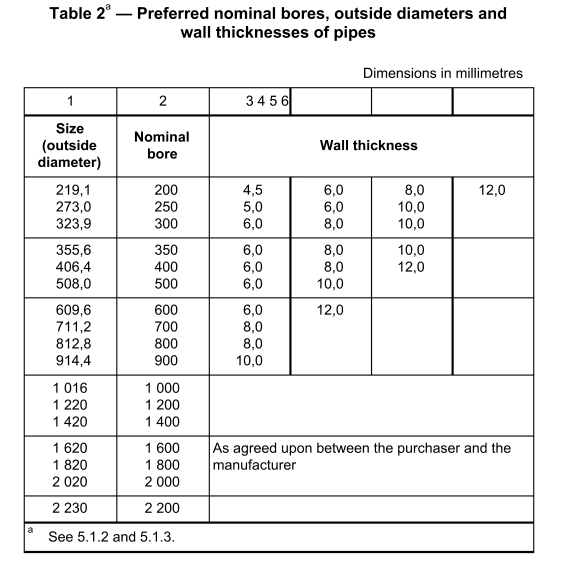

20. Ukubekezelelana:

-Ububanzi Bangaphandle

-Ubukhulu bodonga

Ubukhulu bodonga lwepayipi, kuncike ekubekezelelekeni okungu-+10% noma -8%, kufanele kube ngenye yamanani afanele anikezwe kumakholomu 3 kuya ku-6 ethebula elingezansi, ngaphandle kokuthi kuvunyelwene ngenye indlela phakathi komenzi nomthengi.

-Ukuqondakala

Noma yikuphi ukuphambuka kwepayipi kusuka emugqeni oqondile, akumele kudlule u-0.2% wobude bepayipi.

Noma yikuphi ukungaguquguquki (ngaphandle kwalokho okubangelwa ukugoba), kwamapayipi anobubanzi bangaphandle obungaphezu kwama-500 mm akumele kudlule u-1% wobubanzi bangaphandle (okungukuthi, ubukhulu be-ovality 2%) noma u-6 mm, noma yikuphi okungaphansi.

Sicela uqaphele ukuthi leli shidi ledatha elinemininingwane linikeza ulwazi oluphelele mayelanaAmapayipi e-SANS 719 Grade CIzidingo ezithile zingase zihluke ngokusekelwe kuphrojekthi kanye nencazelo eqondile yepayipi edingekayo.

Isikhathi sokuthunyelwe: Ephreli-28-2024