Iyini i-flange?

I-Flange ngamafuphi, igama elijwayelekile nje, ngokuvamile libhekisela emzimbeni wensimbi ofanayo ofana nediski ukuvula imigodi embalwa egxilile, esetshenziselwa ukuxhuma ezinye izinto, lolu hlobo lwento lusetshenziswa kabanzi emishinini, ngakho-ke lubukeka lungavamile kancane, inqobo nje uma lwaziwa ngokuthi i-flange, igama lalo lisuselwa ku-flange yesiNgisi. Ukuze ipayipi kanye nokuxhumana kwepayipi kwezingxenye, kuxhunywe ekugcineni kwepayipi, i-flange ibe nomgodi, izikulufo zokwenza ama-flange amabili axhunywe kahle, phakathi kwe-flange nge-gasket seal.

I-Flange iyizingxenye ezimise okwediski, ezivame kakhulu kubunjiniyela bamapayipi, i-flange isetshenziswa ngamabili.

Ngokuphathelene nezinhlobo zokuxhumeka kwe-flange, kunezingxenye ezintathu:

- Ama-flange epayipi

- I-Gasket

- Ukuxhumeka kwe-Bolt

Ezimweni eziningi, kutholakala i-gasket ethile kanye nezinto ze-bolt ezenziwe ngezinto ezifanayo nengxenye ye-flange yepayipi. Ama-flange avame kakhulu ama-flange ensimbi engagqwali. Ama-flange, ngakolunye uhlangothi, atholakala ngezinto ezahlukahlukene ukuze ahambisane nezidingo zesayithi. Ezinye zezinto ze-flange ezivame kakhulu yi-monel, i-inconel, kanye ne-chrome molybdenum, kuye ngezidingo zangempela zesayithi. Ukukhetha okungcono kwezinto kufanele kuncike ohlotsheni lwesistimu ofisa ukusebenzisa kuyo i-flange enezidingo ezithile.

Izinhlobo Ezi-7 Ezivamile Zama-Flanges

Kunezinhlobo ezahlukene zama-flanges ezingakhethwa ngokuya ngezidingo zendawo. Ukuze kuhambisane nomklamo we-flange efanelekile, ukusebenza okuthembekile kanye nokuphila isikhathi eside kwenkonzo kumele kuqinisekiswe futhi intengo efanele kakhulu kufanele icatshangelwe.

1. i-flange enezintambo:

Ama-flange anezintambo, anentambo embotsheni ye-flange, afakwe izintambo zangaphandle endaweni yokuhlanganisa. Ukuxhumeka kwezintambo lapha kuhloselwe ukugwema ukushisela kuzo zonke izimo. Kuxhunywe kakhulu ngokufanisa izintambo nepayipi elizofakwa.

2. Ama-flange okushisela amasokhethi

Lolu hlobo lwe-flange luvame ukusetshenziselwa amapayipi amancane lapho ububanzi bendawo yokushisa ephansi kanye nengcindezi ephansi bubonakala ngokuxhumeka lapho ipayipi lifakwa khona ngaphakathi kwe-flange ukuqinisekisa ukuxhumana nge-fillet weld eyodwa noma eminingi. Lokhu kugwema imingcele ehlotshaniswa neziphetho ezinezintambo uma kuqhathaniswa nezinye izinhlobo ze-flange ezihlanganisiwe, okwenza ukufakwa kube lula.

3. Ama-flange e-Lap

I-flange ye-lap uhlobo lwe-flange oludinga ukuthi ingxenye ye-stub ihlanganiswe ngezinqe endaweni yokuhlanganisa ukuze isetshenziswe ne-flange yokusekela ukwakha uxhumano lwe-flanged. Lo mklamo wenze le ndlela yathandwa kakhulu ezinhlotsheni ezahlukene lapho isikhala esibonakalayo silinganiselwe, noma lapho kudingeka khona ukuhlukaniswa okuvamile, noma lapho kudingeka khona izinga eliphezulu lokugcinwa.

4. Ama-flange ashelelayo

Ama-flange ashelelayo avame kakhulu futhi atholakala ngobukhulu obahlukahlukene ukuze avumelane nezinhlelo ezinamazinga aphezulu okugeleza kanye nokuphuma kwawo. Ukuhlanganisa i-flange nobubanzi bangaphandle bepayipi kwenza ukuxhumana kube lula kakhulu ukukufaka. Ukufakwa kwala ma-flanges kuyinto yobuchwepheshe njengoba kudinga ukushiselwa kwe-fillet ezinhlangothini zombili ukuze kuqiniswe i-flange epayipini.

5. Ama-flange angaboni

Lezi zinhlobo zama-flange zilungele kahle ukuqeda izinhlelo zamapayipi. Ipuleti eliyimpumputhe libunjwe njengediski engenalutho engaboshwa ngebhawodi. Uma lokhu sekufakwe kahle futhi kuhlanganiswe ne-gasket efanele, kuvumela ukuvalwa okuhle kakhulu futhi kulula ukukususa uma kudingeka.

6. Ama-Flanges Entanyeni Ashibilikayo

Ama-flange entamo e-Weld afana kakhulu nama-flange e-lap, kodwa adinga ukushisela ama-butt ukuze afakwe. Futhi ubuqotho bokusebenza kwalesi simiso kanye nekhono laso lokugoba kaningi futhi lisetshenziswe ezinhlelweni zokucindezela okuphezulu kanye nokushisa okuphezulu kwenza kube ukukhetha okuyinhloko kwamapayipi enqubo.

7. Ama-flange akhethekile

Lolu hlobo lweflange yilona olujwayelekile kakhulu. Kodwa-ke, kunezinhlobo eziningi zeflange ezikhethekile ezengeziwe ezitholakalayo ukuze zivumelane nokusetshenziswa okuhlukahlukene kanye nezindawo. Kunezinye izinketho ezahlukahlukene ezifana namaflange e-nipo, amaflange e-weldo, amaflange okunwebeka, ama-orifice, izintambo ezinde zokuwelda kanye namaflange okunciphisa.

Izinhlobo Ezi-5 Ezikhethekile Zama-Flanges

1. I-WeldoFi-lange

I-Weldo flange ifana kakhulu ne-Nipo flange njengoba iyinhlanganisela yama-flange okushisela izinqe kanye nokuxhumeka kokufakwa kwamagatsha. Ama-flange e-Weldo enziwe ngensimbi eyodwa eqinile eyakhiwe, kunokuba izingxenye ngazinye zihlanganiswe ndawonye.

2. I-flange ye-Nipo

I-Nipoflange iyipayipi legatsha eligobile nge-engeli yama-degree angu-90, iwumkhiqizo owenziwe ngokuhlanganisa ama-flange okushisela izinqe kanye ne-Nipolet eqinisiwe. Nakuba i-Nipo flange itholakala iyingxenye eyodwa eqinile yensimbi eqinisiwe, akuqondakali ukuthi iyimikhiqizo emibili ehlukene ehlanganisiwe. Ukufakwa kwe-Nipoflange kuqukethe ukushisela engxenyeni ye-Nipolet yemishini ukuze kuqhutshwe ipayipi bese kufakwa ingxenye ye-flange ku-flange yepayipi eliyisicaba yiqembu lamapayipi.

Kubalulekile ukwazi ukuthi ama-Nipo flanges atholakala ngezinhlobo ezahlukene zezinto ezifana ne-carbon, izinsimbi ze-carbon ezishisa kakhulu neziphansi, amazinga ensimbi engagqwali, kanye nama-nickel alloys. Ama-Nipo flanges enziwa kakhulu ngokwenziwa okuqinisiwe, okusiza ukuwanika amandla engeziwe omshini uma kuqhathaniswa ne-Nipo flange ejwayelekile.

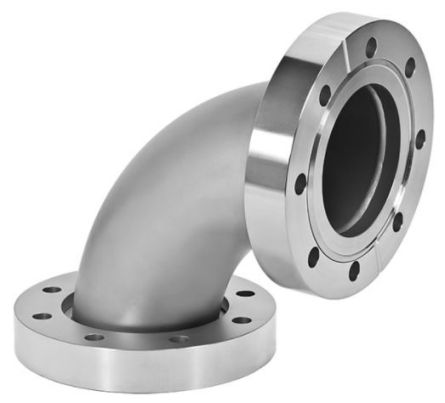

3. I-Elboflange ne-Latroflange

I-Elboflange yaziwa njengenhlanganisela ye-flange ne-Elbolet kanti i-Latroflange yaziwa njengenhlanganisela ye-flange ne-Latrolet. Ama-elbow flange asetshenziselwa amapayipi egatsha nge-engeli engama-degree angu-45.

4. Ama-flange endandatho ajikelezayo

Ukusetshenziswa kwama-flanges endandatho ejikelezayo kuhloselwe ukwenza kube lula ukuvumelanisa imigodi yamabholithi phakathi kwama-flanges amabili abhangqiwe, okuwusizo kakhulu ezimweni eziningi, njengokufakwa kwamapayipi amakhulu, amapayipi angaphansi komhlaba noma asogwini kanye nezindawo ezifanayo. Lezi zinhlobo zama-flanges zifanelekela uketshezi oludingayo ku-oyili, igesi, ama-hydrocarbon, amanzi, amakhemikhali kanye nezinye izinhlelo zokusebenza ze-petrochemical kanye nokuphathwa kwamanzi.

Uma kwenzeka amapayipi amakhulu, ipayipi lifakwe i-flange ejwayelekile ye-butt weld ngakolunye uhlangothi kanye ne-flange ejikelezayo kolunye. Lokhu kusebenza ngokumane kujikelezise i-flange ejikelezayo epayipini ukuze opharetha afinyelele ukulungelelaniswa okufanele kwemigodi yamabholithi ngendlela elula kakhulu futhi esheshayo.

Ezinye zezindinganiso ezinkulu zama-flanges ezindandatho ezijikelezayo yi-ASME noma i-ANSI, i-DIN, i-BS, i-EN, i-ISO, nezinye. Enye yezindinganiso ezithandwa kakhulu zokusetshenziswa kwe-petrochemical yi-ANSI noma i-ASME B16.5 noma i-ASME B16.47. Ama-flanges ajikelezayo angama-flanges angasetshenziswa kuzo zonke izimo ezijwayelekile ze-flange. Isibonelo, ama-weld neck, ama-slip ons, ama-lap joints, ama-socket welds, njll., kuzo zonke izinhlobo zezinto zokwakha, ngobukhulu obuhlukahlukene kusukela ku-3/8" kuya ku-60", kanye nokucindezela kusuka ku-150 kuya ku-2500. Lawa ma-flanges angenziwa kalula nge-carbon, i-alloy, kanye nezinsimbi ezingagqwali.

5. Ama-flange okunweba

Ama-flange okwandisa, asetshenziselwa ukwandisa usayizi webhore lepayipi kusuka kunoma iyiphi indawo ethile kuya kwenye ukuze kuxhunywe ipayipi kunoma yimiphi eminye imishini yemishini efana namaphampu, ama-compressor, nama-valve atholakala enobukhulu obuhlukene bokungena.

Ama-flange okwandisa avame ukuba ama-flange ahlanganiswe ngezinqe anomgodi omkhulu kakhulu ekugcineni okungagobekile. Angasetshenziswa ukwengeza usayizi owodwa noma emibili noma amasentimitha angu-4 ebhoreni lepayipi eligijimayo. Lezi zinhlobo zama-flange ziyathandwa kunokuhlanganiswa kwama-butt-weld reducers kanye nama-flange ajwayelekile ngoba ashibhile futhi alula. Enye yezinto ezivame ukusetshenziswa kuma-flange okwandisa yi-A105 kanye nensimbi engagqwali i-ASTM A182.

Ama-flange okwandisa atholakala ngezilinganiso zokucindezela kanye nosayizi ngokuhambisana nemininingwane ye-ANSI noma i-ASME B16.5, atholakala ngokuyinhloko njenge-convex noma i-flat (RF noma i-FF). Ama-flange okunciphisa, aziwa nangokuthi ama-flange okunciphisa, asebenza umsebenzi ophambene kakhulu uma kuqhathaniswa nama-flange okwandisa, okusho ukuthi asetshenziselwa ukunciphisa usayizi we-bore wepayipi. Ububanzi be-bore bokugijima kwepayipi bungancishiswa kalula, kodwa hhayi ngosayizi ongaphezu ko-1 noma 2. Uma kwenziwa umzamo wokunciphisa ngale kwalokhu, kufanele kusetshenziswe ikhambi elisekelwe ekuhlanganisweni kwama-reducer afakwe izinqe kanye nama-flange ajwayelekile.

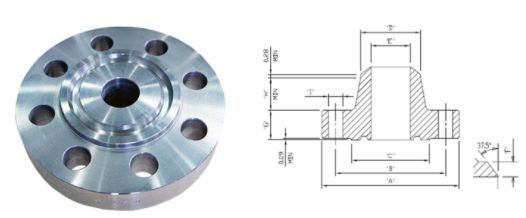

Usayizi we-Flange kanye nokucatshangelwa okuvamile

Ngaphezu komklamo osebenzayo we-flange, ubukhulu bayo yisona sici esingathinta kakhulu ukukhethwa kwe-flange lapho kuklanywa, kugcinwa futhi kubuyekezwa uhlelo lwamapayipi. Esikhundleni salokho, kufanele kucatshangelwe ukuxhumeka kwe-flange nepayipi kanye nama-gasket asetshenziswa ukuqinisekisa usayizi ofanele. Ngaphezu kwalokhu, ezinye izinto ezivamile okufanele zicatshangelwe yilezi ezilandelayo:

- Ububanzi bangaphandle: Ububanzi bangaphandle buyibanga eliphakathi kwemiphetho emibili ephambene yobuso be-flange.

- Ubukhulu: Ubukhulu bulinganiswa kusukela ngaphandle komphetho.

- Ububanzi beBolt Circle: Leli ibanga eliphakathi kwezimbobo zebolt ezilinganiswa ukusuka enkabeni kuya enkabeni.

- Usayizi Wepayipi: Usayizi wepayipi usayizi ohambisana neflange.

- I-Nominal Bore: I-nominal bore iwusayizi wobubanzi bangaphakathi besixhumi se-flange.

Ukuhlukaniswa kweFlange kanye neZinga Lesevisi

Ama-flange ahlukaniswa ngokuyinhloko ngekhono lawo lokubekezelela amazinga okushisa ahlukene kanye nezingcindezi. Achazwa ngokusebenzisa izinhlamvu noma izijobelelo "#", "lb" noma "class". Lezi izijobelelo ezishintshaniswayo futhi ziyahlukahluka ngokwesifunda noma umhlinzeki. Izigaba ezivamile ezaziwayo zibalwe ngezansi:

- 150#

- 300#

- 600#

- 900#

- 1500#

- 2500#

Ukubekezelelana okufanayo kwengcindezi kanye nokushisa kuyahlukahluka kuye ngezinto ezisetshenzisiwe, ukwakheka kweflange kanye nosayizi weflange. Kodwa-ke, okuwukuphela kwento engaguquki isilinganiso sengcindezi, esinciphayo njengoba izinga lokushisa likhuphuka.

Uhlobo Lobuso Be-Flange

Uhlobo lobuso luyisici esibaluleke kakhulu esinomthelela omkhulu ekusebenzeni kokugcina kanye nokuphila kwenkonzo yeflange. Ngakho-ke, ezinye zezinhlobo ezibaluleke kakhulu zobuso beflange zihlaziywa ngezansi:

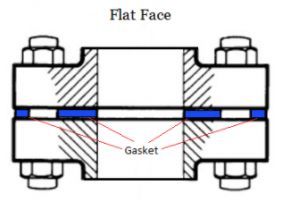

1. I-Flange Eyisicaba (FF)

Ubuso be-gasket ye-flange eyisicaba busendizeni efanayo nobuso bohlaka olunamabholidi. Izimpahla ezisebenzisa ama-flange asicaba ngokuvamile yilezo ezenziwe ngezimonyo ukuze zifane nesembozo se-flange noma se-flange. Ama-flange asicaba akufanele abekwe kuma-flange ahlangothini aguquliwe. I-ASME B31.1 ithi lapho kuhlanganiswa ama-flange ensimbi eyisicaba kuma-flange ensimbi ye-carbon, ubuso obuphakanyisiwe kuma-flange ensimbi ye-carbon kumele bususwe futhi kudingeka i-gasket egcwele ubuso. Lokhu kwenzelwa ukuvimbela ama-flange ensimbi eyisicaba amancane, aqhekekayo ukuthi angangeni endaweni engenalutho eyakhiwe yikhala eliphakanyisiwe le-flange yensimbi ye-carbon.

Lolu hlobo lobuso be-flange lusetshenziswa ekwenziweni kwemishini nama-valve azo zonke izinhlelo zokusebenza lapho kwenziwa khona insimbi ephonswe. Insimbi ephonswe iyaphuka kalula futhi ivame ukusetshenziswa kuphela ekusetshenzisweni kokushisa okuphansi, okunomfutho ophansi. Ubuso obuyisicaba buvumela ama-flange womabili ukuthi axhumane ngokuphelele phezu kwendawo yonke. Ama-Flat Flanges (FF) anobuso bokuthinta obulingana nobude bezintambo ze-flange. Ama-washer obuso obugcwele asetshenziswa phakathi kwama-flanges amabili ayisicaba futhi avame ukuba mnene. Ngokusho kwe-ASME B31.3, ama-flanges ayisicaba akufanele ahlanganiswe nama-flanges aphakeme ngenxa yokuthi kungenzeka ukuthi kuphume i-flange ephumayo.

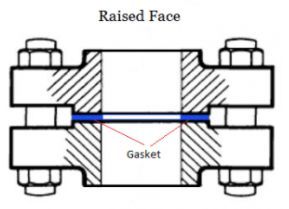

2. I-Flange Enobuso Obuphakanyisiwe (RF)

I-flange yobuso obuphakanyisiwe uhlobo oluvame kakhulu olusetshenziswa ekusetshenzisweni kwabakhiqizi futhi iyabonakala kalula. Ibizwa ngokuthi i-convex ngoba ubuso be-gasket butholakala ngaphezu kobuso bendandatho yebholidi. Uhlobo ngalunye lobuso ludinga ukusetshenziswa kwezinhlobo eziningana zama-gasket, kufaka phakathi amathebhu ahlukahlukene endandatho eyisicaba kanye nezinhlanganisela zensimbi ezifana nezinhlobo ze-spiral-wound kanye nezinhlobo ze-double-sheathed.

Ama-flange e-RF aklanyelwe ukugxila ingcindezi eyengeziwe endaweni encane ye-gasket, ngaleyo ndlela kuthuthukiswe ukulawulwa kwengcindezi yejoyinti. ububanzi nokuphakama ngokwezinga lokucindezela nobubanzi kuchazwe ku-ASME B16.5. Izinga lokucindezela kwe-Flange lichaza ukuphakama kobuso obuphakanyiswayo. Ama-flange e-RF ahloselwe ukugxila ingcindezi eyengeziwe endaweni encane ye-gasket, ngaleyo ndlela andise ikhono lokulawula ingcindezi lejoyinti. Ububanzi nokuphakama ngokwesigaba sokucindezela nobubanzi kuchazwe ku-ASME B16.5. Izilinganiso ze-flange yokucindezela.

3. I-Flange yendandatho (RTJ)

Uma kudingeka uphawu lwensimbi oluvela kunsimbi phakathi kwama-flange abhangqiwe (okuyisimo sokusetshenziswa komfutho ophezulu kanye nokushisa okuphezulu, okungukuthi, ngaphezu kuka-700/800 C°), kusetshenziswa i-Ring Joint Flange (RTJ).

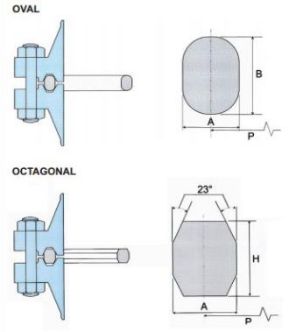

I-flange ye-ring joint inomsele oyindilinga ohlanganisa i-gasket ye-ring joint (eyindilinga noma engunxande).

Uma ama-flange amabili e-ring joint ehlanganiswa ndawonye bese eqiniswa, amandla e-bolt asetshenziswayo aguqula i-gasket emseleni we-flange, okudala uphawu oluqinile kakhulu lwensimbi nensimbi. Ukuze kufezwe lokhu, izinto ze-gasket e-ring joint kumele zibe thambile (zibe bushelelezi kakhulu) kunezinto ze-flange.

Ama-RTJ flanges angavalwa ngama-gasket e-RTJ ezinhlobo ezahlukene (R, RX, BX) kanye namaphrofayili (isb., i-octagonal/elliptical yohlobo lwe-R).

I-gasket ye-RTJ evame kakhulu uhlobo lwe-R olune-cross-section engu-octagonal, njengoba iqinisekisa uphawu oluqinile kakhulu (i-oval cross-section iwuhlobo oludala). Kodwa-ke, umklamo "we-flat groove" wamukela zombili izinhlobo zama-gasket e-RTJ ane-cross-section engu-octagonal noma engu-oval.

4. Ama-flange olimi kanye ne-groove (T & G)

Ama-flange amabili olimi kanye ne-groove (ubuso be-T & G) afanelana kahle: i-flange eyodwa inendandatho ephakanyisiwe kanti enye ine-groove lapho ingena khona kalula (ulimi lungena emseleni bese luvala i-joint).

Ama-flange olimi kanye ne-groove ayatholakala ngobukhulu obukhulu nobuncane.

5. Ama-Flanges Abesilisa Nabesifazane (M & F)

Njengoba kunjalo ngama-flange olimi kanye nama-groove, ama-flange abesilisa nabesifazane (izinhlobo zobuso be-M & F) ayafanelana.

I-flange eyodwa inendawo edlula indawo yayo engaphezulu, i-flange yesilisa, kanti enye i-flange inezindawo ezifanayo ezifakwe ebusweni obubheke phezulu, i-flange yesifazane.

Ukuqeda Komphezulu We-Flange

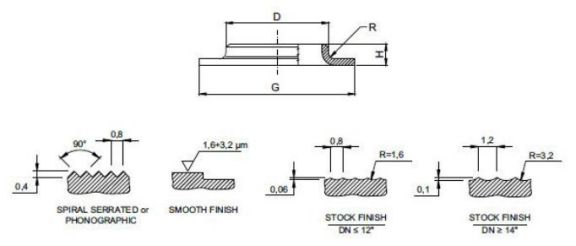

Ukuze kuqinisekiswe ukuthi i-flange ilingana kahle ne-gasket kanye ne-flange yokuhlangana, indawo yobuso be-flange idinga izinga elithile lobukhali (ukuphela kwe-flange ye-RF kanye ne-FF). Uhlobo lobukhali bobuso be-flange luchaza uhlobo "lokuphela kwe-flange".

Izinhlobo ezivamile ubuso be-flange obubushelelezi, obunezimbobo eziqinile, obunezimbobo ezijikelezayo kanye nobuso be-flange obubushelelezi.

Kunezinhlobo ezine zokuqeda okuyisisekelo kwe-flanges zensimbi, nokho, umgomo ojwayelekile wanoma yiluphi uhlobo lokuqeda kwe-flanges ukukhiqiza ubulukhuni obufunwayo ebusweni be-flange ukuqinisekisa ukulingana okuqinile phakathi kwe-flange, i-gasket kanye ne-flange yokuhlanganisa ukuze kuhlinzekwe uphawu lwekhwalithi.

Isikhathi sokuthunyelwe: Okthoba-08-2023