1.Ukubuka Konke Komkhiqizo

I-Womic Steel igxile ekukhiqizweni kwamapayipi ethusi asezingeni eliphezulu ahambisana nezinga le-EN 1057. Lawa mapayipi enziwe ngezinto ze-Cu-DHP (CW024A), okuqinisekisa ukuhlanzeka nokusebenza kahle kakhulu kwezicelo zokufaka amapayipi, ukusatshalaliswa kwegesi, ukufudumeza, kanye nokupholisa. Ngokuqukethwe okuncane kwethusi nesiliva okungu-99.9% kanye ne-phosphorus elawulwayo ephakathi kuka-0.015% no-0.040%, amapayipi ethu ethusi abonisa ukumelana okuhle kakhulu nokugqwala, ukuqina, kanye nokulula kokufakwa.

Amapayipi ethusi e-EN 1057 aklanyelwe ukusetshenziswa ezindaweni zasekhaya nasezimbonini, enikeza ukusebenza okuthembekile ezinhlelweni zamanzi aphuzwayo, ekufudumaleni okuphakathi, efrijini, kanye nasemipayipini yegesi yezokwelapha. Njengoba ekhiqizwe ngezindinganiso zekhwalithi eziqinile, la mapayipi anikeza izakhiwo zemishini eziphakeme kanye nokuthembeka kwenkonzo yesikhathi eside.

2.I-EN 1057 I-Copper Tubes Production Range

●Ububanzi Bangaphandle (OD):6 mm kuya ku-267 mm

●Ubukhulu Bodonga (WT):0.3mm kuya ku-20mm

●Ubude:Ubude obujwayelekile obungu-3m, 5m, noma 6m; ubude obungokwezifiso buyatholakala uma uceliwe

●Amapayipi Ahlanganisiwe:Itholakala ngamakhoyili angu-25m noma angu-50m ukuze ifakeke kalula

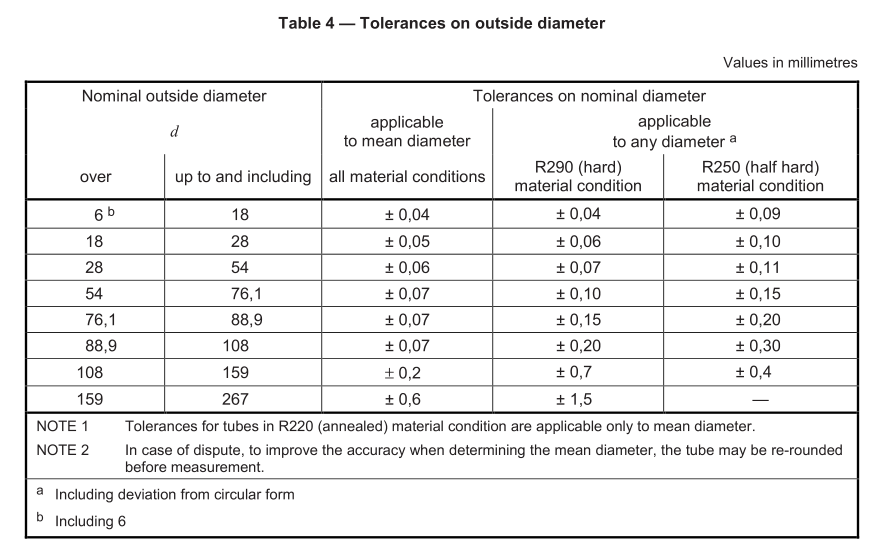

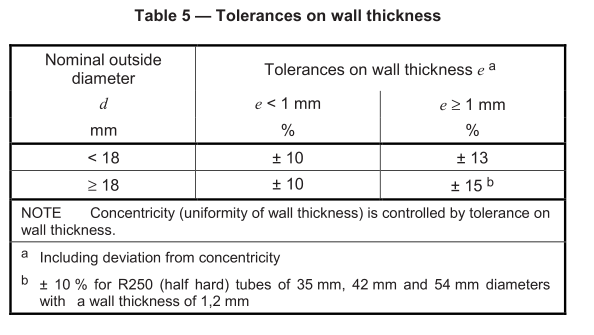

3.I-EN 1057 I-Copper Tubes Tolerances

I-Womic Steel iqinisekisa ukunemba okunembile kobukhulu ngezilinganiso ezilandelayo:

4.EN 1057 Amashubhu Ethusi Ukwakheka Kwamakhemikhali

Amashubhu ethu ethusi akhiqizwa ngezinto ze-Cu-DHP (CW024A) eziqukethe okulandelayo:

Ukwakheka kufanele kuhambisane nezidingo ezilandelayo:

I-Cu + Ag: ubuncane 99,90 %;

0,015 %≤P≤0,040 %.

Leli banga lethusi libizwa ngokuthi i-Cu-DHP noma i-CW024A.

Lokhu kuhlanganiswa kuqinisekisa ukumelana okuhle kakhulu nokugqwala, ukuhanjiswa okuphezulu kokushisa kanye nogesi, kanye nokusebenza kahle kakhulu.

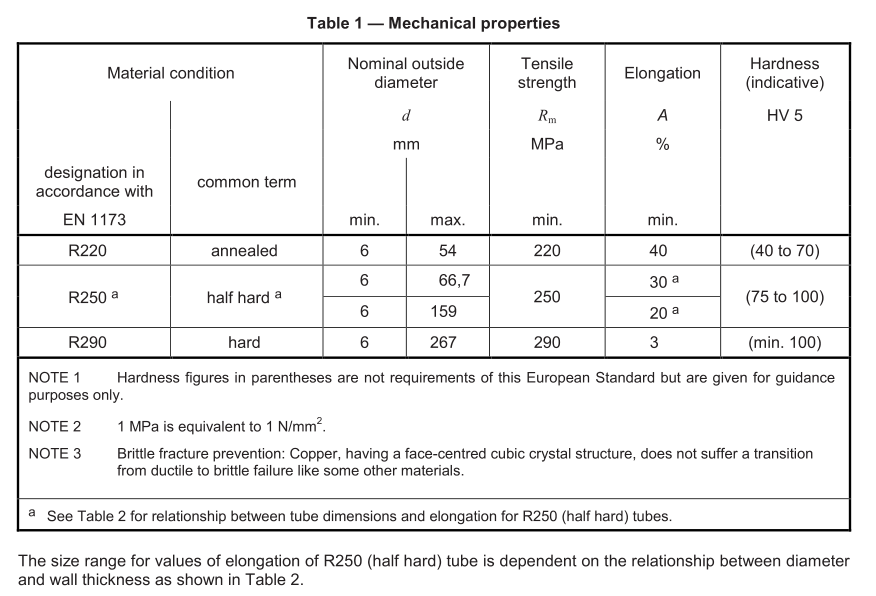

5.Izakhiwo Zemishini Yamapayipi Ethusi e-EN 1057

Izakhiwo zemishini zamashubhu ethu ethusi e-EN 1057 zincike esimweni sokulethwa:

6.Izimo Zokulethwa Kwamashubhu Ethusi e-EN 1057

I-Womic Steel inikeza amashubhu ethusi e-EN 1057 kulezi zimo ezilandelayo:

●R220 (Efakwe uphawu): Iguquguquka kakhulu, ifanele ukugoba nokwakha

●R250 (Half-Hald): Amandla aphakathi nendawo, ibhalansi enhle yokuguquguquka nokuqina

●R290 (Iqinile): Amandla aphezulu, afanele ukusetshenziswa okuqondile nokugoba okuncane

7.Inqubo Yokukhiqiza Amashubhu Ethusi e-EN 1057

Inqubo yethu yokukhiqiza ethuthukisiwe iqinisekisa amazinga aphezulu kakhulu:

1. Ukulungiselela Ukuthunga Nokubumba: Ithusi elicwengekile kakhulu liyancibilikiswa bese liphonswa kuma-billet.

2. Ukukhipha Nokubhoboza: Ama-billet akhishwa abe yi-tube bese ebhobozwa ngokwezilinganiso ezidingekayo.

3. Umdwebo Obandayo: Amapayipi adonswa ngamadayi ukuze kufezwe ubukhulu obuqondile.

4. Ukufakwa kwe-Annealing: Ukwelashwa ngokushisa kusetshenziswa ukuze kufezwe izakhiwo ezidingekayo zemishini.

5. Ukuqondisa Nokusika: Amapayipi ayaqondiswa futhi anqunywe ngobude obudingekayo.

6. Ukuhlolwa Nokuhlolwa: Ukuhlolwa kwekhwalithi okuqinile kuqinisekisa ukuhambisana nezindinganiso ze-EN 1057.

8.Ukuhlola Nokuhlola

I-Womic Steel iqinisekisa ukulawulwa kwekhwalithi okugcwele ngokuhlolwa okuphelele, okuhlanganisa:

●Ukuhlaziywa Kwamakhemikhali/Kwe-Spectrographic: Ukuqinisekiswa kokwakheka kwezinto kusetshenziswa izindlela zamakhemikhali noma ze-spectroscopic.

●Ukuhlolwa Kokudonseka: Ukuhlolwa kwamandla okudonseka kanye nezakhiwo zokunwebeka (EN 10002-1).

●Ukuhlolwa Kobulukhuni: Ukulinganiswa kobulukhuni bezinto ngendlela kaVickers (EN ISO 6507-1).

●Ukuhlolwa Kokuqukethwe Kwekhabhoni: Ukunqunywa kwenani lephesenti lekhabhoni kusetshenziswa indlela yokubhekisela ye-EN 723.

●Ukuhlolwa Kwefilimu Yekhabhoni: Ukutholwa nokuhlolwa kokuba khona kwefilimu yekhabhoni (Isijobelelo B).

●Ukuhlolwa Kokugoba: Ukuhlolwa kokugoba ngaphansi

●Ukuhlolwa Kokukhulisa Ukukhukhuleka: Ukwandiswa kokuphela kwepayipi ngo-30% nge45°i-mandrel ekhonjisiwe ukuqinisekisa ukuqina kwayo (EN ISO 8493).

●Ukuhlolwa Kokugoba: Ukuqinisekiswa kokwakheka kwe-flange (ubuncane bokwenyuka okungu-30% kobubanzi beshubhu) kusetshenziswa ithuluzi elinobubanzi bekona obungu-1 mm (EN ISO 8494).

●Ukuhlolwa Kwenkululeko Ebubini:

●Ukuhlolwa Kwamanje kwe-Eddy (ECT): Ukutholwa kwamaphutha aphezulu/angaphansi komhlaba (EN 1971 & Annex C.1).

●Ukuhlolwa kwe-Hydrostatic: Ukuqinisekiswa kokumelana nengcindezi ngokucindezela kwamanzi (Isijobelelo C.2).

●Ukuhlolwa Komoya: Ukutholwa kokuvuza kusetshenziswa umfutho womoya/igesi (Isijobelelo C.3).

●Qaphela: Imiyalelo yokuhlola uhlobo lokuqala i-ECT; ezinye izindlela zikhethwa ngumenzi.

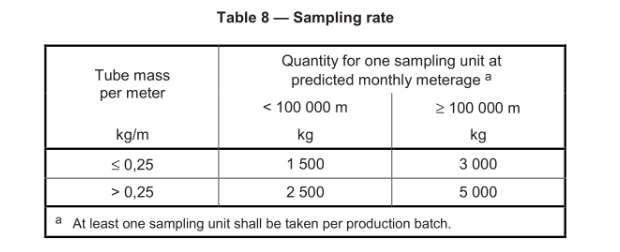

9. Ukuthatha amasampula:

Ngenhloso yokuqinisekisa ikhwalithi ngesikhathi sokukhiqiza, inani lamayunithi okusampula okufanele athathwe ngokungahleliwe kufanele libengokuvumelana neThebula 8.

Lezi zilinganiso zokuthatha amasampula zizosebenza lapho kuhlolwa izilawuli zobukhulu; ukulawulwa kwezinye izakhiwo ezidingekayo kuzokwenziwa kuyunithi ngayinye yesampula yesibili.

Imiphumela ingasetshenziswa kusukela ekuhlaziyweni okwenziwe esigabeni sokuqala sokukhiqiza umkhiqizo, isb. esigabeni sokukhipha noma sokufaka ama-billets, uma ukuhlonza umkhiqizo kugcinwa futhi uma uhlelo lokuphatha ikhwalithi lomenzi luhambisana nezidingo ezifanele ze-EN lSO 9001.

10.Ukupakisha

Ukuqinisekisa ukuphathwa nokuthuthwa okuphephile, amashubhu ethu ethusi apakishwa kanje:

●Isimbozo Esilwa Nokushiswa Kwe-Oxidation: Kufakwa ungqimba oluvikelayo ebusweni bamashubhu ethusi ukuvimbela ukushiswa kwe-oxidation kanye nokushintsha kombala ngesikhathi sokugcina kanye nokuthuthwa.

●Ama-End Caps: Ama-plastic noma ama-metal cap amelana nokugqwala afakwa emaphethelweni epayipi ukuvimbela ukungcola kanye nomonakalo wemishini.

●Ukubopha: Amapayipi ahlanganiswe ngokwezimfuneko futhi aboshelwe ngokuphephile ngamabhande epulasitiki aqinile ukuze kuncishiswe ukunyakaza ngesikhathi sokuthutha.

●Izikebhe Zokhuni: Amashubhu ahlanganisiwe afakwa emabhokisini okhuni angangenisi umswakama. Amabhokisi ambozwe nge-foam engangeni manzi noma izinto zokuhlanza ukuze kuvinjelwe ukulimala komswakama futhi kuhambisane nezindinganiso ze-ISPM 15 zamazwe ngamazwe ze-phytosanitary.

●Ukuvala Okuqinisiwe: Ama-crate avalwa ngamabhande ensimbi noma izibambo ezisindayo. Ukugoqa okuncishisiwe okungakhethwa kuyatholakala ukuze kuvikelwe isimo sezulu esengeziwe.

●Ukubhala Amalebula: Ibhokisi ngalinye libhalwe ngobubanzi bangaphandle bepayipi (OD), ubukhulu bodonga (WT), ubude, isimo sezulu (isb., uthambile, uhhafu-uqinile), inombolo yebhetshi yokukhiqiza, kanye nosuku ukuqinisekisa ukulandeleka okugcwele.

11.Ezokuthutha kanye Nezokuthutha

I-Womic Steel iqinisekisa ukulethwa kwamashubhu ethusi e-EN 1057 ngesikhathi nangokuphephile:

●Ukuthunyelwa Kwasolwandle: Ukuthunyelwa komhlaba wonke ngamabhodlela anezibambo ezifanele

●Ezokuthutha Ngesitimela Noma Emgwaqweni: Ukulethwa okuthembekile kwasekhaya nakwesifunda

●Ezokuthutha Ezilawulwa Yisimo Sezulu: Ziyatholakala kuzinhlelo zokusebenza ezibucayi

●Amadokhumenti Aphelele: Amadokhumenti okuthumela kanye nomshuwalense kuhlinzekiwe

●Ithusi Elihlanzekile Kakhulu: Ukuqina Okumangalisayo kanye nokumelana nokugqwala

●Ukukhiqiza Ngokunembile: Ukubekezelelana okuqinile kobukhulu bokusebenza okuthembekile

●Izixazululo Zenziwe Ngokwezifiso: Ubude obufanele, izimo zokushisa, kanye nokugqoka kuyatholakala

●Ukuhlolwa Okuphelele: Ukuqinisekisa ukuhambisana nezindinganiso zomhlaba wonke

●Ukusabalalisa Komhlaba Wonke: Ukulethwa okuthembekile nokufika ngesikhathi emhlabeni wonke

12.Izinzuzo Zokukhetha Insimbi Yabesifazane

- ●Ithusi Elihlanzekile Kakhulu: Ukuqina Okumangalisayo kanye nokumelana nokugqwala

- ●Ukukhiqiza Ngokunembile: Ukubekezelelana okuqinile kobukhulu bokusebenza okuthembekile

- ●Izixazululo Zenziwe Ngokwezifiso: Ubude obufanele, izimo zokushisa, kanye nokugqoka kuyatholakala

- ●Ukuhlolwa Okuphelele: Ukuqinisekisa ukuhambisana nezindinganiso zomhlaba wonke

- ●Ukusabalalisa Komhlaba Wonke: Ukulethwa okuthembekile nokufika ngesikhathi emhlabeni wonke

13.Izicelo

Amashubhu ethusi e-EN 1057 asetshenziswa kabanzi ku:

- Izinhlelo Zokufaka Amapayipi: Ukusatshalaliswa kwamanzi ahlanzekile okuphephile nokuthembekile

- Ukusatshalaliswa Kwegesi: Kulungele ukusetshenziswa kwegesi yemvelo kanye ne-LPG

- Izinhlelo Zokushisa: Ukusebenza kahle kuma-radiator kanye nokushisa okungaphansi komhlaba

- Isiqandisi kanye ne-Air Conditioning: Ukushisa okuphezulu kwezinhlelo zokupholisa

- Amapayipi Egesi Yezokwelapha: Athembeke ezibhedlela ukuze athole umoya-mpilo kanye namagesi ezokwelapha

Isiphetho

Amashubhu ethusi e-EN 1057 e-Womic Steel anikeza ikhwalithi ephezulu, amandla, kanye nokuthembeka kwezicelo zamapayipi, igesi, kanye nezimboni. Ukuzibophezela kwethu ekukhiqizeni ngokunemba, ukuhlolwa okuqinile, kanye nezixazululo ezigxile kumakhasimende kusenza sibe ngumlingani othembekile embonini.

Khetha i-Womic Steel Group njengomlingani wakho othembekile wekhwalithi ephezuluAmapayipi Ethusi&Ukufakwa kanye nokusebenza kokulethwa okungenakuqhathaniswa. Siyakwamukela Umbuzo!

Iwebhusayithi: www.womicsteel.com

I-imeyili: sales@womicsteel.com

Ucingo/I-WhatsApp/I-WeChat: Victor: +86-15575100681 noma uJack: +86-18390957568

Isikhathi sokuthunyelwe: Mashi-10-2025