Yonke imikhiqizo yensimbi ekhandwayo kanye nensimbi ekhandiwe ingenziwa ngokwezifiso ze-OEM ngokwemidwebo evela kumakhasimende. Futhi singahlela ukukhiqizwa kwe-oda ngokwemidwebo oyinikezile.

Imikhiqizo yensimbi yokusakaza:Izimbiza ze-slag, ibhande lamasondo e-rotary kiln, izingxenye ze-crusher (i-Mantles & Concave, i-Bowl Liners), izingxenye zomshini wokumba, izingxenye ezisele ze-Electric Shovel (i-track shoe),

Imikhiqizo yensimbi eyenziwe ngobumba:I-Gear, Ama-Gear Shaft, Ama-Cylindrical Gears, ama-OEM design gears, ama-roller shafts, ama-shafts kanye nezixazululo.

Ububanzi Bezinto:I-ASTM A27 GR70-40, ZGMn13Mo1, ZGMn13Mo2, ZG25CrNi2Mo, 40CrNi2Mo, SAE H-13, AISI 8620, ZG45Cr26Ni35, ZG40Cr28Ni48W5Si2, ZG35Cr20Ni80

Insimbi Ehlanganisiwe 4340 (36CrNiMo4), i-AISI 4140 Insimbi /42CrMoS4, i-UNS G43400, 18CrNiMo7-6, 17NiCrMo6-4, 18NiCrMo5, 20NiCrMo2-2, 18CrNiMo7-6, 14NiCrMo13-4, 20NiCrMo13-4, ZG35Cr28Ni16, ZGMn13Mo2

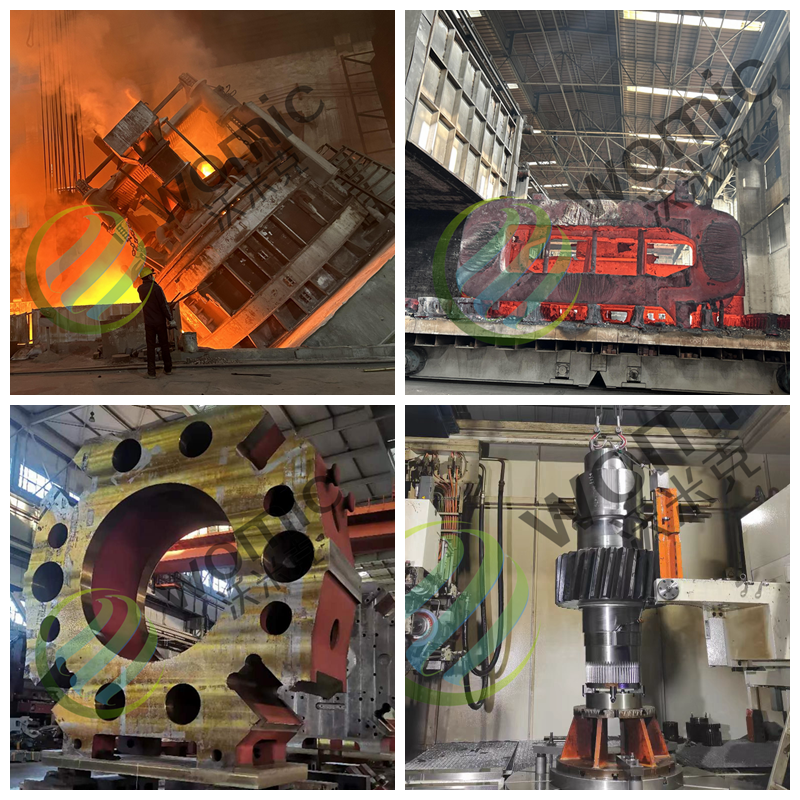

I-WOMIC STEEL iphinde ibe nendawo yokusebenzela eyaziwayo yokwenziwa kwensimbi yemikhiqizo yensimbi yokubumba kanye nemikhiqizo yensimbi yokubumba enyakatho yeShayina. Imikhiqizo eminingi yensimbi yokubumba ihlinzekwa emhlabeni wonke, njengeMexico, eNingizimu-Melika, e-Italy, eYurophu, e-United States, eJapane, eRussia, eNingizimu-mpumalanga ye-Asia njalonjalo. Ngolwazi oluningi lwenqubo yensimbi yokubumba kanye nensimbi yokubumba, i-WOMIC STEEL iphinde ithuthukise ubuchwepheshe benqubo ngokuqhubekayo. Igiya elikhulu le-ball mill girth, izinhlobo ezahlukene zamagiya, i-gear shaft, i-supporting roller, amabhodwe e-slag asetshenzisiwe okumbiwa ngethusi, imishini, izingxenye ezisele ze-Electric Shovel (izicathulo zomkhondo), izingxenye ze-crusher (ama-Mantles nama-Concave, ama-Bowl Liners), kanye nomhlathi ohambayo okhiqizwa yiyo kudonsele amakhasimende amaningi aphesheya kwezilwandle ukuvakashela inkampani. Futhi kwabenza baneliseka ngemikhiqizo yethu.

Ngemva kweminyaka engama-20 yokukhiqiza kanye nesipiliyoni sokuthengisa embonini yokukhipha, manje sinethimba lobuchwepheshe elinolwazi futhi elinekhono, elikhethekile ekukhiqizeni izinsimbi ezinkulu nezinkulu kakhulu. Inqubo yokukhiqiza isebenzisa ukuthululwa okuhlangene, ukuhlelwa kwensimbi encibilikisiwe kanye kuphela okungamathani angu-450, kanti isisindo esiphezulu sokukhipha singafinyelela amathani angaba ngu-300. Imboni yomkhiqizo ihilela ukumbiwa kwezimayini, usimende, umkhumbi, ukwakheka, insimbi, ibhuloho, ukugcinwa kwamanzi, Isikhungo esisodwa sokukhiqiza (iqembu) (5 TK6920 CNC imishini yokubhoboza kanye nokugaya, 13 CNC 3.15M~8M ikholomu ephindwe kabili i-lathe eqondile (iqembu), 1 CNC 120×3000 umshini wokugoqa ipuleti elisindayo, amasethi ayi-6φUmshini wokufaka igiya ongu-1.25m-8m (iqembu)) njalo njalo.

Imishini yokukhiqiza kanye nemishini yokuhlola isiqediwe. Umthamo omkhulu wokuphakamisa imoto eyodwa ungamathani angu-300, kanye nesithando somlilo esisodwa sikagesi esingamathani angu-30 namathani angu-80, isithando somlilo esisodwa se-LF esineziteshi ezimbili esingamathani angu-120, umshini owodwa wokuqhumisa itafula ojikelezayo ongu-10m*10m, izithando ezintathu zokushisa okuphezulu zokushisa ezingama-12m*7m*5m, 8m*4m*3.5m, 8m*4m*3.3m, kanye no-8m*4M *3.3m. Indawo yokuhlunga ingamamitha-skwele angu-30,000 imishini yokususa uthuli lwesithando somlilo sikagesi esingamathani.Isikhungo sokuhlola esizimele sihlonyiswe nge-laboratory yamakhemikhali, i-spectrometer yokufunda ngqo, umshini wokuhlola umthelela, umshini wokuhlola ukuthambekela, i-ultrasonic flaw detector, i-Leeb hardness tester, i-Metallographic phase microscope, njll.

Noma nini lapho sihlola khona endaweni, ukuze ukholwe ukuthi izinto ezenziwe ngensimbi kanye nemikhiqizo eyenziwe ngensimbi ekhiqizwe yi-WOMIC STEEL inekhwalithi enhle kanye nokuphila isikhathi eside kwenkonzo, okungahlangabezana kahle namakhasimende.'izidingo zomklamo.

Ukuze kuxazululwe isimo sokungcola okuphezulu kanye nokusetshenziswa kwamandla aphezulu,I-WOMIC STEEL isebenzisa izitofu zikagesi ezisebenza ngesivinini esiphakathi futhi ifake abaqoqi bothuli endaweni yokusebenzela. Manje, indawo yokusebenza yendawo yokusebenzela ithuthukisiwe kakhulu. Esikhathini esidlule, i-coke yayishiswa, kodwa ugesi manje ususetshenziswa, okungagcini nje ngokunciphisa ukusetshenziswa kwamandla, konga amandla futhi kuvikele imvelo, kodwa futhi kuthuthukisa ukunemba komkhiqizo.

I-WOMIC STEEL izothuthukisa kakhulu izinsiza zehadiwe zefektri, isekele imishini yokwenza izinto ngokuzenzakalela, ukusetshenziswa kwezinqubo ezizenzakalelayo zokuqoqa izingxenye, ukuhlanza nokupholisha, kanye nokufutha okuzenzakalelayo, njll., ukwandisa izinga lokwenza izinto ngokuzenzakalela lenqubo yokukhiqiza libe ngaphezu kuka-90%, futhi iqhubeke nokuthuthukisa ubuchwepheshe.

Umehluko phakathi kwemikhiqizo yensimbi ephonswayo kanye nemikhiqizo yensimbi ephonswayo:

Okokuqala, inqubo yokukhiqiza ihlukile

Inqubo yokukhiqiza izinto zokubopha kanye nezinto zokubopha insimbi ihlukile. Insimbi ehlanganisiwe ibhekisela kuzo zonke izinhlobo zezinto zokubopha kanye nezinto zokubopha ezikhiqizwa ngendlela yokubopha; Insimbi ehlanganisiwe insimbi esetshenziselwa ukuphonsa izinto zokubopha. I-Forging ukugoqa izinto zokusetshenziswa zibe yisimo nosayizi ofiselekayo ngomthelela kanye nokuguqulwa kwepulasitiki kwezinto zensimbi. Ngokuphambene nalokho, izinto zokubopha insimbi zenziwa ngokuthulula insimbi encibilikisiwe kumodeli elungiselelwe kusengaphambili, eqina futhi ipholiswe ukuze kutholakale isimo nosayizi ofiselekayo. Insimbi ehlanganisiwe ivame ukusetshenziswa ekwenziweni kwezingxenye ezibalulekile zomshini; Insimbi ehlanganisiwe isetshenziswa kakhulu ukukhiqiza ezinye izimo eziyinkimbinkimbi, okunzima ukuzibumba noma ukuzisika futhi idinga izingxenye ezinamandla aphezulu kanye ne-plasticity.

Okwesibili, isakhiwo sezinto sihlukile

Isakhiwo sezinto zokwakha kanye nezinsimbi zokuthunga nazo zihlukile. Izinsimbi zokuthunga ngokuvamile ziyafana kakhulu futhi zinamandla angcono kanye nokumelana nokukhathala. Ngenxa yesakhiwo sekristalu esiqinile sezinsimbi zokuthunga, azikwazi ukuguquka nokuqhuma kokushisa lapho zithwalwa. Ngokuphambene nalokho, isakhiwo sensimbi yokuthunga sikhululekile, okulula ukukhiqiza ukuguqulwa kwepulasitiki kanye nomonakalo wokukhathala ngaphansi kwesenzo somthwalo.

Okwesithathu, izici zokusebenza ezahlukene

Izici zokusebenza kwe-forgings kanye ne-castings nazo zihlukile. I-Forgings inokumelana nokuguguleka okuphezulu nokugqwala futhi ifanelekela amandla aphezulu kanye nemithwalo yemvamisa ephezulu. Ngokuphambene nalokho, ukumelana nokuguguleka kanye nokumelana nokugqwala kwezingxenye zensimbi ezibunjiwe kuphansi kakhulu, kodwa ine-plasticity enhle.

Isikhathi sokuthunyelwe: Juni-26-2024