1. Ukubuka Konke Komkhiqizo

I-Womic Steel ingumkhiqizi othembekile wamapayipi ethusi asezingeni eliphezulu ahambisana ne-I-ASTM B88amazinga, ikakhulukaziUhlobo Limininingwane eyenziwe kusukelaI-C12200 (i-phosphorus-deoxidized, i-phosphorus eseleyo ephezulu)ithusi. Lawa mapayipi ethusi aqinile asetshenziswa kabanziamapayipi, i-HVAC, ukuvikelwa komlilo, igesi, kanye nezinhlelo ezijwayelekile zokusetshenziswangenxa yokumelana kwazo okuhle kakhulu nokugqwala, ukuqina, kanye nokwakheka kahle.

Ithusi le-C12200 liqukethe iphesenti eliphezulu lethusi elimsulwa kanye nenani elincane le-phosphorus, okuthuthukisa ukushibilika kwalo kanye nokumelana nokuqhekeka kwe-hydrogen. Amapayipi ohlobo lwe-L ashaya ibhalansi efanele phakathi kobukhulu bodonga kanye nesisindo, enikeza ukuthembeka kokubili ekufakweni okungaphezulu komhlaba kanye nangaphansi komhlaba.

2. Uhla Lokukhiqiza

- Ububanzi Bangaphandle (OD):6 mm kuya ku-219 mm

- Ubukhulu Bodonga (WT):0.3 mm kuya ku-10 mm

- Ubude:Ubude obujwayelekile be3m, 5m, 6m, kanyeubude obufanele buyatholakala uma uceliwe

- Amapayipi Ahlanganisiwe:Kutholakala ku-Amakhoyili angu-25m noma angu-50mukufakwa okuguquguqukayo kuma-heat exchangers

- Ukuphela Kokuphela:Isiphelo esilula, sihlanziwe futhi sisusiwe; sitholakala ngezivalo noma ngaphandle kwazo

3. Ukubekezelelana Okulinganayo (Amashubhu Ethusi e-ASTM B88 C12200)

I-Womic Steel iqinisekisa ukunemba okunembile kobukhulu be-C12200amashubhu ahambisana neI-ASTM B88amazinga. Kusebenza lezi zindlela ezilandelayo zokubekezelelana:

I-ASTM B88 - Ithebula 1: Ubukhulu, Isisindo, kanye Nokubekezelelana Kosayizi Wepayipi Lamanzi Ethusi

| Usayizi Ojwayelekile (ngaphakathi) | Ububanzi Bangaphandle (ngaphakathi) | Ukubekezelelana kwe-OD (Okuncishisiwe) | Ukubekezelelana kwe-OD (Okudwetshwe) | Uhlobo K Wall (ngaphakathi) | Uhlobo K Tol. (ngaphakathi.) | Uhlobo L Udonga (ngaphakathi) | Uhlobo L Tol. (ngaphakathi) | Uhlobo M Udonga (ngaphakathi) | Uhlobo M Tol. (ngaphakathi.) |

| 1/4 | 0.375 | 0.002 | 0.001 | 0.035 | 0.0035 | 0.03 | 0.003 | C | C |

| 3/8 | 0.5 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.035 | 0.004 | 0.025 | 0.002 |

| 1/2 | 0.625 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.04 | 0.004 | 0.028 | 0.003 |

| 5/8 | 0.75 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.042 | 0.004 | C | C |

| 3/4 | 0.875 | 0.003 | 0.001 | 0.065 | 0.006 | 0.045 | 0.004 | 0.032 | 0.003 |

| 1 | 1.125 | 0.0035 | 0.0015 | 0.065 | 0.006 | 0.05 | 0.005 | 0.035 | 0.004 |

| 1 1/4 | 1.375 | 0.004 | 0.0015 | 0.065 | 0.006 | 0.055 | 0.006 | 0.042 | 0.004 |

| 1 1/2 | 1.625 | 0.0045 | 0.002 | 0.072 | 0.007 | 0.06 | 0.006 | 0.049 | 0.005 |

| 2 | 2.125 | 0.005 | 0.002 | 0.083 | 0.008 | 0.07 | 0.007 | 0.058 | 0.006 |

| 2 1/2 | 2.625 | 0.005 | 0.002 | 0.095 | 0.01 | 0.08 | 0.008 | 0.065 | 0.006 |

| 3 | 3.125 | 0.005 | 0.002 | 0.109 | 0.011 | 0.09 | 0.009 | 0.072 | 0.007 |

| 3 1/2 | 3.625 | 0.005 | 0.002 | 0.12 | 0.012 | 0.1 | 0.01 | 0.083 | 0.008 |

| 4 | 4.125 | 0.005 | 0.002 | 0.134 | 0.013 | 0.11 | 0.011 | 0.095 | 0.01 |

| 5 | 5.125 | 0.005 | 0.002 | 0.160 | 0.016 | 0.125 | 0.012 | 0.109 | 0.011 |

| 6 | 6.125 | 0.005 | 0.002 | 0.192 | 0.019 | 0.14 | 0.014 | 0.122 | 0.012 |

| 8 | 8.125 | 0.008 | 0.002/-0.004 | 0.271 | 0.027 | 0.2 | 0.02 | 0.17 | 0.017 |

| 10 | 10.125 | 0.008 | 0.002/-0.006 | 0.338 | 0.034 | 0.25 | 0.025 | 0.212 | 0.021 |

| 12 | 12.125 | 0.008 | 0.002/-0.006 | 0.405 | 0.04 | 0.28 | 0.028 | 0.254 | 0.025 |

A Ububanzi obuphakathi nendawo bepayipi buyisilinganiso sobubanzi obukhulu nobuncane bangaphandle, njengoba kunqunywa kunoma iyiphi ingxenye eyodwa yepayipi.

B Ukuphambuka okukhulu kunoma yiliphi iphuzu elilodwa.

C Kubonisa ukuthi izinto azitholakali ngokuvamile noma ukuthi akukho ukubekezelelana okuqinisekisiwe

Lokhu kubekezelelana kuqinisekisa ukuthi amapayipi ayahlanganaizidingo zokunemba okuphezulu kanye nekhwalithi, okwenza zifanelekeizicelo zezimboni nezasolwandle ezidinga kakhulu.

3. Ukwakheka Kwamakhemikhali (C12200 – ASTM B88)

Isici Ukwakheka (% ngesisindo)

Ithusi (Cu) MinB≥ 99.9 (kufaka phakathi isiliva)

I-Phosphorus (P) 0.015 – 0.040

I-oxygen kufanele ibe yi-10 ppm max.

B Ithusi + isiliva ≤ 0.04

Okuqukethwe kwe-phosphorus kuthuthukisa ukushibilika kanye nokumelana nokuqhekeka kokucindezeleka, kuyilapho kugcinwa ukuhanjiswa okuphezulu kokushisa kanye nogesi.

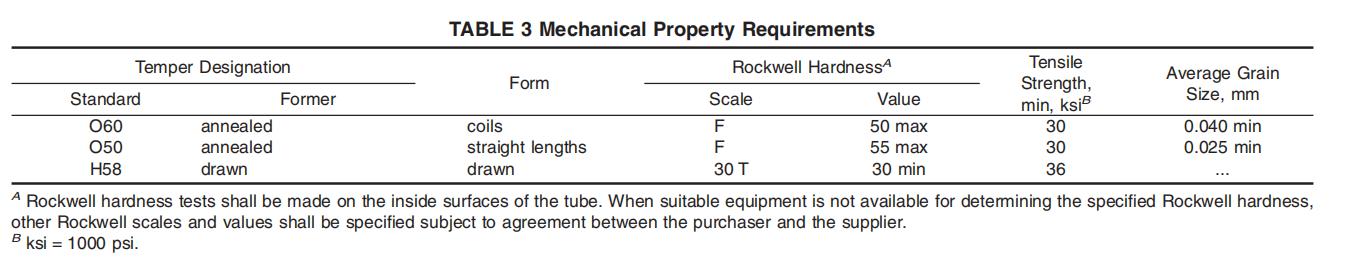

4. Izakhiwo Zemishini

Ipayipi lethusi eliqinile lohlobo L livame ukuhlinzekwa ngesimo sezulu esiqinile (esidonswe), elifanele izinhlelo zokucindezela kanye nokufakwa okuqondile.

5. Izimo Zokulethwa

I-Womic Steel ihlinzeka ngamapayipi ethusi ohlobo L ngaphansi kwezimo ezilandelayo:

Ulaka Oluqinile (H58):Ubude obuqondile bezinhlelo zokucindezela

I-Annealed Temper (O60):Kuyatholakala uma kuceliwe ngezicelo ezidinga ukugoba nokwakheka

6. Inqubo Yokukhiqiza

I-Womic Steel iqinisekisa ukunemba okuphezulu kanye nekhwalithi ngezinyathelo ezilandelayo:

- Ukuncibilikisa Nokuphonsa:Ithusi elicwengekile kakhulu liyancibilikiswa bese liphonswa ezinhlamvini.

- Ukukhipha:Ama-billet akhishwa abe yisimo se-tubular.

- Umdwebo Obandayo:Amapayipi adonswa ngobukhulu bokugcina kanye nobukhulu.

- Ukufakwa kwe-Annealing (ongakukhetha):Uma kudingeka, lungisa ukushisa ukuze unciphise ulaka.

- Ukuqondisa Nokusika:Amapayipi anqunywa ngobude obujwayelekile noma obungokwezifiso.

- Ukuhlanza Nokuhlola:Izindawo zangaphakathi nezangaphandle ziyahlanzwa futhi ziyahlolwa.

- Ukumaka Nokupakisha:Amapayipi aphawulwe nge-ASTM B88, uhlobo, kanye nosayizi ukuze kulandeleke kahle.

7. Ukuhlolwa Nokuhlolwa

I-Womic Steel iqinisekisa amazinga aphezulu kakhulu ngokwenzaukuhlolwa okuqinile nokuhlolwa, kufaka phakathi:

- Ukuhlaziywa Kokwakheka Kwamakhemikhali:Ukuqinisekiswa kusetshenziswa ukuhlaziywa kwamakhemikhali okubonakalayo noma okumanzi

- Ukuhlolwa Kokunamathela:Ukuqinisekisa amandla nobude kuhlangabezana nezidingo ze-ASTM B88

- Ukuhlolwa Kokuqina:Kukalwe kusetshenziswaIndlela kaVickers

- Ukuhlolwa Kokukhulisa Ukushayela:Ukwandiswa kokuphela kwepayipi ngu30%usebenzisai-mandrel engu-45° eyindilinga

- Ukuhlolwa Kokuthamba:Ukuhlolwa kweukukhubazeka kanye nokumelana nokuqhekeka

- Ukuhlolwa Kwamanje kwe-Eddy (ECT):Ukutholwa kweamaphutha aphezulu nangaphansi komhlaba

- Ukuhlolwa Kokucindezela Okungangenisi Umoya:Ukuqinisekisa ukuthi amapayipi ayamelanaingcindezi yangaphakathi ngaphandle kokuvuza

8. Ukuthatha amasampula

Ukusampula nokuhlola kwenziwa ngokwemigomo ye-ASTM B88 kanye ne-QA yangaphakathi. Amasampula okuhlola akhethwa ngokungahleliwe kusuka kuhlu ngalunye ukuze:

l Okuqukethwe kwamakhemikhali

l Izakhiwo zemishini

l Ukunemba kobukhulu

l Isimo somphezulu

9. Ukupakisha

Ukuqinisekisaukuphathwa okuphephile kanye nokuthuthwa, I-Womic Steel inikezaizixazululo zokupakisha eziqinile, kufaka phakathi:

- Isimbozo Sokulwa Nokuvundisa:Isendlalelo esivikelayo sisetshenziswa ukuvimbela ukugqwala ngesikhathi sokugcina kanye nokuthutha

- Ama-Caps Okugcina:Izivalo zepulasitiki noma zensimbi eziphethweni zamapayipi ukuvimbela ukungcola

- Ukuhlanganisa:Ibhande eliqinile elinamabhande epulasitiki noma ensimbi ukuze liqine

- Ibhokisi Lokhuni:Kupakishwe ngaphakathiamabhokisi ezinkuni angangeni umswakamangendwangu ye-foam evikelayo

- Ukulebula:Iphakheji ngayinye ilebula elithiI-OD, i-WT, ubude, i-temperature, inombolo ye-batch, kanye nosuku lokukhiqiza

10. Ezokuthutha kanye Nezokuthutha

I-Womic Steel iqinisekisaukulethwa ngesikhathi nangokuphephilengokusebenzisa:

- Impahla Yasolwandle:Kuphephileukuthunyelwa okunamakhonteyina ukuze kusatshalaliswe emhlabeni jikelele

- Ezokuthutha Ngesitimela Nomgwaqo:Ukulethwa okuthembekile kwamakhasimende esifunda

- Ukuphathwa Okukhethekile:Izinketho ezilawulwa yisimo sezulu zezinhlelo zokusebenza ezibucayi

- Imibhalo Ephelele:KubandakanyaIzitifiketi Zokuhlolwa Kwemishini (i-MTC), Imibiko Yokuthobela Izinto Ezibalulekile, kanye Nomshuwalense

- Ukumelana Okuphezulu Kokugqwala:Kuhle kakhuluizinhlelo zokusebenza zokudlulisa amanzi, amakhemikhali, kanye nokushisa

- Ukukhiqiza Ngokucophelela:Okuqinileukubekezelelana okunobukhuluukuze kusebenze kahle kakhulu

- Izixazululo Zenziwe Ngokwezifiso:Osayizi, izimo zokushisa, kanye nokugqoka okulungiselelwe ukuhlangabezana nezidingo ezithile

- Ukuhlolwa Okuphelele:Ukuqinisekisa ukuthobela ngokugcweleI-ASTM B88

- Inethiwekhi Yokusabalalisa Yomhlaba Wonke:Ukulethwa okusheshayo nokuthembekile emhlabeni wonke

11. Izinzuzo Zokukhetha Insimbi Yabesifazane

12. Izicelo

OkwethuI-ASTM B88 C12200amashubhu afaneleka kakhulu ku:

- Imboni Yasolwandle: Ama-condenser apholile ngamanzi olwandle, amapayipi, kanye nezishintshi zokushisa zebhodi lemikhumbi

- Izitshalo Zikagesi:Ama-condenser omusi kanyeizinhlelo zokupholisa

- Izitshalo Zokususa Usawoti:Amapayipi angagqwali okusetshenziswa kwamanzi anosawoti

- Ukucubungula Amakhemikhali:Amashubhu okushintshanisa ukushisa anengcindezi ephezulu, anezinga lokushisa eliphezulu

- I-HVAC kanye nefriji: Amakhoyili omoya opholile kanye nezinhlelo zokupholisa zezimboni

Isiphetho

Amapayipi ethusi e-Womic Steel e-ASTM B88 C12200 Type L anikeza ukusebenza okuhle kakhulu, ukuqina, kanye nokumelana nokugqwala, okwenza abe ukukhetha okuthandwayo kwezinhlelo eziningi zamapayipi. Ngokunamathela ngokuqinile ezindinganisweni ze-ASTM kanye nokuqinisekiswa kwekhwalithi okuphelele, siqinisekisa ukuthi ukulethwa ngakunye kuhlangabezana nokulindelwe okuphezulu ekusebenzeni nasekuthembekeni.

Siyaziqhenya nge-izinsizakalo zokwenza ngokwezifiso, imijikelezo yokukhiqiza esheshayo, futhiinethiwekhi yokulethwa komhlaba wonke, ukuqinisekisa ukuthi izidingo zakho ezithile ziyahlangatshezwa ngokunemba nangobungcweti.

Iwebhusayithi: www.womicsteel.com

I-imeyili: sales@womicsteel.com

Ucingo/I-WhatsApp/I-WeChat: Victor: +86-15575100681 noma uJack: +86-18390957568

Isikhathi sokuthunyelwe: Jan-21-2026