Ipayipi lensimbi ye-ASTM A335 Grade P9 alloy iyipayipi lensimbi ye-chromium-molybdenum alloy elenzelwe ngqoisevisi yokushisa okuphezulu kanye nokucindezela okuphezuluNjengenye yezinhlobo ze-Cr-Mo alloy ezisetshenziswa kakhulu,I-ASTM A335 P9idlala indima ebalulekile ekukhiqizeni ugesi, ekucutshungulweni kwe-petrochemical, ezinhlelweni zamapayipi okuhlanza, kuma-boiler, kanye nasemishinini yokudlulisa ukushisa.

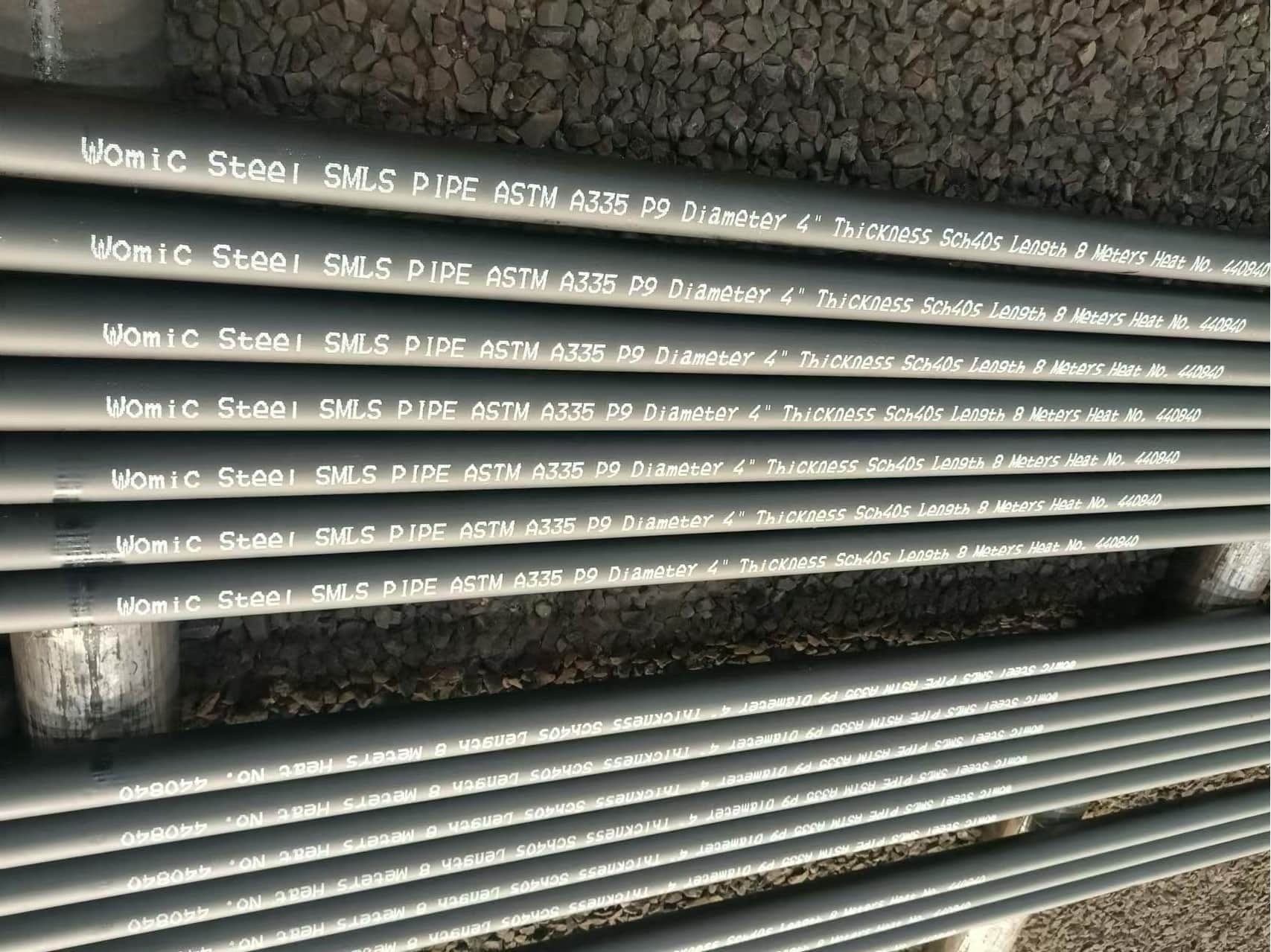

Njengomkhiqizi nomthengisi onolwazi,I-Womic Steel igxile ekukhiqizweni nasekuhlinzekweni kwamapayipi ensimbi angenamthungo e-ASTM A335 P9, enikeza ikhwalithi ezinzile, ukuhambisana ngokugcwele nezimfuneko ze-ASTM A335, kanye nokulethwa okusheshayo okusekelwa yisitokwe esivamile sosayizi abavamile.

1. Isizinda Esijwayelekile kanye Nesikhundla se-ASTM A335 P9

I-ASTM A335 iyisimbozo semininingwane ejwayelekileipayipi lensimbi ye-ferritic alloy engenamthungo eyenzelwe isevisi yokushisa okuphezuluNgaphakathi kwale nqubo,I-ASTM A335 Ibanga P9ichazwa ngokwakheka kwayo kwamakhemikhali okulinganiselwe okungaba ngu-I-9% ye-Chromium kanye ne-1% ye-Molybdenum, okuyihlukanisa nezinhlobo eziphansi ze-alloy njenge-P5 noma i-P11.

Uma kuqhathaniswa namapayipi ensimbi yekhabhoni,Ipayipi lensimbi ye-ASTM A335 P9 alloyinikeza ukumelana okuthuthukisiwe kakhulu kwe-oxidation, amandla okuhamba, kanye nokuqina kokushisa. Uma kuqhathaniswa namazinga aphansi e-chromium alloy,I-A335 P9inikeza ukumelana okuthuthukisiwe kokukala kanye nokuwohloka kwesakhiwo esincane emazingeni okushisa aphezulu.

2. Ukusetshenziswa Okuvamile Kwepayipi Lensimbi Ye-ASTM A335 P9 Alloy

Amapayipi e-ASTM A335 P9 akhethwa kakhulu ezinhlelweni ezisebenza ngaphansiizinga lokushisa eliphezulu eliqhubekayo kanye nengcindezi, lapho ukuthembeka kwesikhathi eside kubalulekile khona.

Izicelo ezivamile zeIpayipi lensimbi ye-ASTM A335 P9 alloyfaka:

- Amapayipi amakhulu omusi ezitshalweni zamandla ezishisayo nezijikelezayo ezihlanganisiwe

- Izinhlelo zamapayipi e-Superheater kanye ne-reheater

- Ama-header nama-manifold okushisa okuphezulu

- Amapayipi enqubo ye-Petrochemical kanye ne-refinery

- Izishintshi zokushisa ezivezwe emazingeni okushisa aphezulu

- Izinhlelo zokucindezela amapayipi ezitshalweni zamakhemikhali

Kuzo zonke lezi zicelo,I-ASTM A335 P9iyaziswa ngekhono layo lokugcina amandla okusebenza kanye nokuqina kobukhulu ngesikhathi sokuchayeka ekushiseni isikhathi eside.

3. Izici ze-Metallurgical ze-ASTM A335 P9

Ukusebenza kweIpayipi lensimbi ye-ASTM A335 Grade P9 alloyihlobene eduze nomklamo wayo wensimbi.

I-Chromium kuI-A335 P9kuthuthukisa ukumelana nokushiswa kwe-oxidation futhi kwakha ama-carbide azinzile athuthukisa amandla okushisa aphezulu. I-Molybdenum inegalelo ekumelaneni nokukhukhuleka futhi inciphisa ukuthambekela kokuthambisa ngesikhathi sokusebenza isikhathi eside. Ndawonye, lezi zinto ezixubayo zinikezaIpayipi lensimbi ye-ASTM A335 P9 alloyukumelana okuhle kakhulu nokukhathala kokushisa kanye nokuwohloka kwesakhiwo esincane.

Ukwelashwa kokushisa okufanele kubalulekile ukuze kuthuthukiswe ngokugcwele lezi zakhiwo, okwenza ukulawula inqubo kube yinto ebalulekile ku-Ukukhiqiza amapayipi e-A335 P9.

4. Inqubo Yokukhiqiza Amapayipi Angenamthungo e-ASTM A335 P9

KwaWomic Steel,Amapayipi ensimbi angenamthungo e-ASTM A335 P9zikhiqizwa kusetshenziswa umzila wokukhiqiza olawulwa ngokucophelela owenzelwe ukuhlangabezana nezidingo ezijwayelekile kanye neziqondene nephrojekthi.

Inqubo yokukhiqiza ivame ukufaka:

l Ukukhethwa kwama-billets ensimbi alloy afanelekayo ahambisana ngokuqinile ne-ASTM A335 P9 chemistry

l Ukubhoboza okushisayo ukuze kwakheke amagobolondo angenalutho

l Ukugoqa okushisayo noma i-extrusion eshisayo ukufeza ubukhulu obuqondiwe

l Ukulinganisa nokuqondisa ngokunemba

l Ukwelashwa kokushisa okuphoqelekile ngokuhambisana ne-ASTM A335

Ukuhlolwa kokugcina, ukuhlolwa, kanye nokumaka

Le nqubo engenamthungo iqinisekisa ukujiya kodonga okufanayo, ukugxila okuhle kakhulu, kanye nezakhiwo zemishini ezihambisanayo kulo lonke ubude be-Ipayipi le-ASTM A335 P9.

5. Izidingo Zokwelashwa Kokushisa ze-ASTM A335 P9

Ukwelashwa ngokushisa kungenye yezigaba ezibaluleke kakhulu ekukhiqizweniIpayipi lensimbi ye-ASTM A335 Grade P9 alloy.

Ngokusho kwe-ASTM A335,Amapayipi e-A335 P9ngokuvamile zihlinzekwa ku-okujwayelekile nokuthambile (N&T)isimo. Inqubo yokwenza kube ngokwejwayelekile ilungisa isakhiwo sezinhlamvu, kuyilapho ukulinganisela kulungisa ubulukhuni nokuqina ukuze kulingane nebhalansi edingekayo.

Ukwelashwa okushisa okufanele kuqinisekisa ukuthiIpayipi lensimbi ye-ASTM A335 P9 alloykufeza:

l Amandla okuqinela azinzile

l Ukuqina okwanele

l Ukumelana nokukhasa okuthuthukisiwe

l Ukuqina kwesakhiwo se-microstructural kwesikhathi eside ekushiseni okuphezulu

I-Womic Steel ilawula ngokuqinile izinga lokushisa lokushisa, isikhathi sokubamba, kanye nezinga lokupholisa ukuqinisekisa imiphumela ehambisanayo yeqoqo ngalinye lezinto.Amapayipi e-A335 P9.

6. Ububanzi Bobukhulu kanye Nokukwazi Ukunikeza

Izimpahla zensimbi zeWomicAmapayipi angenamthungo e-ASTM A335 P9ebangeni elibanzi elifanele ukusetshenziswa kwezimboni eziningi.

l Ububanzi Bangaphandle: kusukela kumapayipi amancane kuya kobubanzi obukhulu

l Ubukhulu beWall: uchungechunge lwe-SCH noma ukujiya okwenziwe ngezifiso

l Ubude: ubude obungahleliwe, ubude obungaguquki, noma obuqondene nephrojekthi ethile

Ukukhiqizwa okuvamile kanye nokuhlela isitokwe kuvumela i-Womic Steel ukuthi inakekeleisitokwe sosayizi wamapayipi avamile e-ASTM A335 P9, kunciphisa kakhulu isikhathi sokuhola izidingo eziphuthumayo.

7. Ukulawulwa Kwekhwalithi Nokuhlolwa Kwamapayipi E-ASTM A335 P9

Ukuqinisekiswa kwekhwalithi kufakiwe kulo lonke ukukhiqizwa kweAmapayipi ensimbi e-alloy e-ASTM A335 P9.

Ukuhlolwa nokuhlolwa kuhlanganisa:

l Ukuhlaziywa kokwakheka kwamakhemikhali ukuqinisekisa okuqukethwe yi-Cr kanye ne-Mo

Ukuhlolwa kokuqina nokuqina

Ukuhlolwa kwe-Hydrostatic noma ukuhlolwa okungabhubhisi (UT / Eddy Current)

Ukuhlolwa kobukhulu kanye nokuhlolwa okubonakalayo

l Ukubuyekezwa kwamarekhodi okwelashwa kokushisa

Ukuthunyelwa ngakunye kweIpayipi le-ASTM A335 P9ihlinzekwa ngezitifiketi zokuhlolwa kwe-Mill ngokuhambisana ne-EN 10204 3.1, okuqinisekisa ukulandeleka okugcwele.

8. Ukucatshangelwa Kokuhambisana Nokushisela kanye Nokukhiqizwa

Ipayipi lensimbi ye-ASTM A335 P9 alloyivame ukushiselwa ngesikhathi sokufakwa. Ngenxa yokuqukethwe kwayo kwe-alloy, izinqubo ezifanele zokushisela zibalulekile.

Ukushisa, izinga lokushisa elilawulwayo le-interpass, kanye nokwelashwa kokushisa ngemuva kokushiswa (i-PWHT) ngokuvamile kuyadingeka ukuze kugcinwe ubuqotho beIzinhlelo zamapayipi e-A335 P9I-Womic Steel inikeza ukwesekwa kobuchwepheshe maqondana nokuziphatha kwezinto ezibonakalayo kanye nokucatshangelwa kokwenziwa lapho kuhlinzekwaAmapayipi e-ASTM A335 P9kumaphrojekthi ayinkimbinkimbi.

9. Inzuzo Yokulethwa kanye Nesikhathi Sokuhola Sokukhiqiza

Enye yamandla ayinhloko e-Womic Steel ukuthembeka kokulethwa kwezimpahlaIpayipi lensimbi ye-ASTM A335 Grade P9 alloy.

l Isitoko esivamile siyatholakala ngobukhulu obujwayelekile

l Amandla okukhiqiza okusheshayo anesikhathi sokuhola esifushane njengezinsuku ezingama-30

l Ukuhlela okuguquguqukayo kwezidingo zephrojekthi eziphuthumayo

Lokhu kuhlanganiswa kokusebenza kahle kwempahla kanye nokukhiqiza kuvumela amakhasimende ukuthi afinyeze imijikelezo yokuthenga yeAmapayipi e-ASTM A335 P9.

10. Ukupakisha kanye Nokuthutha Komhlaba Wonke

Amapayipi ensimbi e-alloy e-ASTM A335 P9zigcwele ukucatshangelwa okugcwele kokuvikela ukugqwala kanye nokuphepha kwezokuthutha.

l Izivalo zokugcina zawo wonke amapayipi

l Ukupakisha okuhlanganisiwe ngezintambo zensimbi noma izisekelo zokhuni

l Ukumaka okucacile okukhomba ibanga le-ASTM A335 P9 kanye nezinombolo zokushisa

l Ukuthunyelwa okufakwe ebhodleleni noma okune-breakbulk kuye ngobukhulu

Ubuchwepheshe bezokuthutha beWomic Steel buqinisekisa ukuthiAmapayipi e-ASTM A335 P9bafike ezindaweni zephrojekthi besesimweni esihle kakhulu.

11. Kungani Kufanele Ukhethe Insimbi Yomhlobiso Yamapayipi Ensimbi Ehlanganisiwe Ye-ASTM A335 P9

l Ulwazi olukhethekile kuUkukhiqizwa kwamapayipi ensimbi engxubevange ye-ASTM A335 P9

l Ukuhambisana okuqinile ne-ASTM A335 standard

l Imibhalo ephelele yekhwalithi kanye nokulawulwa kokuhlolwa

Ukutholakala kwesitoko kanye nekhono lokukhiqiza elisheshayo lezinsuku ezingama-30

l Ukusekelwa okuthembekile kwempahla yomhlaba wonke kanye nokuthunyelwa kwamanye amazwe

Siyaziqhenya nge-izinsizakalo zokwenza ngokwezifiso, imijikelezo yokukhiqiza esheshayo, futhiinethiwekhi yokulethwa komhlaba wonke, ukuqinisekisa ukuthi izidingo zakho ezithile ziyahlangatshezwa ngokunemba nangobungcweti.

Iwebhusayithi: www.womicsteel.com

I-imeyili: sales@womicsteel.com

Ucingo/I-WhatsApp/I-WeChat: Victor: +86-15575100681 noma uJack: +86-18390957568

Isikhathi sokuthunyelwe: Jan-19-2026