Ama-Flanges e-ASTM A182 e-Alloy-Steel ahlanganisiwe noma asongiwe, i-Forged Fittings, nama-Valve

I-ASTM A182 iyincazelo ebalulekile yama-flange ensimbi ehlanganisiwe noma egoqiwe, izinto zokufakelwa ezihlanganisiwe, nama-valve aklanyelwe ukusetshenziswa ezindaweni ezinokushisa okuphezulu, ezinomfutho ophezulu. Leli zinga linikeza iziqondiso zokwakheka kwamakhemikhali, izakhiwo zemishini, izindlela zokuhlola, nezinye izinto ezibalulekile eziqinisekisa ukuqina nokuthembeka kwalezi zingxenye ezisetshenziswayo ezibalulekile.

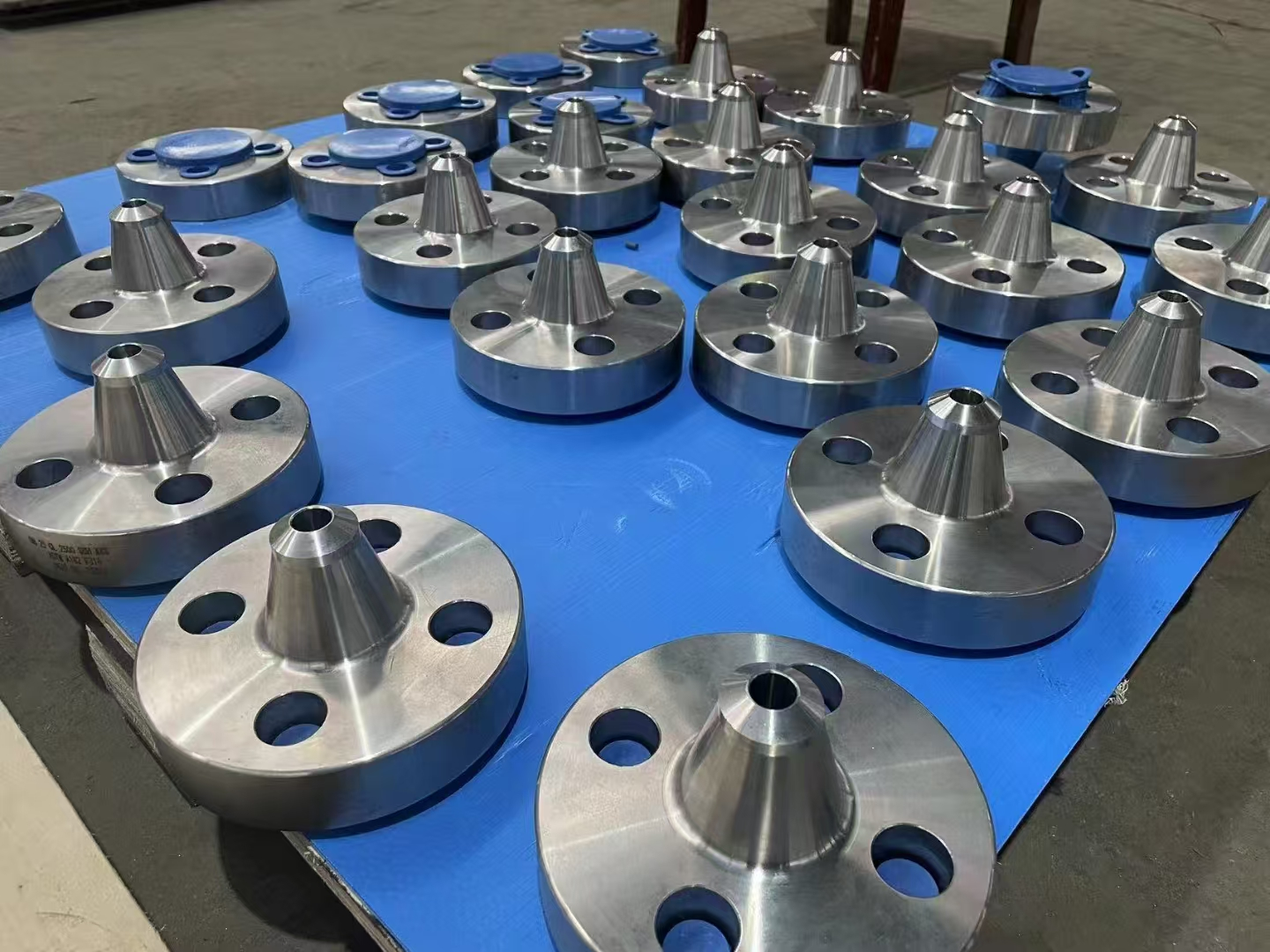

KwaWomic Steel, sakha imikhiqizo eminingi ehambisana nezinga le-ASTM A182, enikeza ikhwalithi ephezulu kanye nokunemba. Kulesi sihloko, sizohlola izinto ezibalulekile zaleli zinga futhi sibonise amakhono okukhiqiza eWomic Steel kanye nezinzuzo zokukhetha thina njengomhlinzeki wakho.

Izinhlobo Zemikhiqizo Embozwe yi-ASTM A182

I-ASTM A182 ihlanganisa izingxenye ezahlukene zensimbi ezibunjiwe noma ezigoqiwe, okuhlanganisa:

1. Ama-Flange – Lawa asetshenziselwa ukuxhuma amapayipi, ama-valve, amaphampu, neminye imishini ohlelweni lwamapayipi.

2. Izinto Zokubopha Ezihlanganisiwe – Lokhu kufaka phakathi izindololwane, ama-tee, ama-reducer, ama-cap, kanye nama-union asetshenziswa ezinhlelweni zokucindezela okuphezulu.

3. Ama-valve – Aklanyelwe ukulawula ukugeleza koketshezi ezindaweni ezishisa kakhulu.

4. Eminye Imikhiqizo Ehlanganisiwe Noma Egoqiwe – Lokhu kufaka phakathi ama-valve kanye nokufakwa okusetshenziswa ku-steam, gas, kanye nezinye izinhlelo zokucindezela okuphezulu.

KwaWomic Steel, sikhiqiza lezi zinto ngobukhulu obuhlukahlukene, izinto zokwakha, kanye nokucushwa, ukuqinisekisa ukuthi ziyahlangabezana nezidingo zakho ezithile zohlelo lokusebenza.

Izinto zokwakha kanye nokwakheka kwamakhemikhali

Izinga le-ASTM A182 licacisa amazinga amaningana ezinto zokwakha, okuhlanganisa insimbi yekhabhoni, insimbi e-alloy ephansi, kanye nensimbi engagqwali, ngayinye inezidingo ezihlukile zokwakheka kwamakhemikhali. Nazi ezinye zezinto ezibalulekile ezimbozwe ngaphansi kwe-ASTM A182:

1. Ibanga F1 – Insimbi yekhabhoni enokwakheka okuyenza isebenze emazingeni okushisa aphakathi nendawo.

2. Ibanga F5, F9, F11, F22 – Izinsimbi ezithambile eziphansi eziklanyelwe ukumelana namazinga okushisa aphezulu kanye nokucindezeleka.

3. Ibanga F304, F304L, F316, F316L – Izinsimbi ezingagqwali ze-Austenitic, ezisetshenziswa kabanzi ngenxa yokumelana kwazo nokugqwala ezindaweni ezahlukene zokucubungula amakhemikhali.

Kuyo yonke ibanga, ukwakheka kwamakhemikhali kulawulwa ngokucophelela ukuze kuhlangatshezwane nezidingo eziqinile ze-ASTM. Ngezansi kunemininingwane yokwakheka kwamakhemikhali kwento ngayinye kanye nezakhiwo zayo.

Ukwakheka Kwamakhemikhali Nezakhiwo Zemishini

1. Ibanga F1 - Insimbi Yekhabhoni

Ukwakheka Kwamakhemikhali:

Ikhabhoni (C): 0.30-0.60%

I-Manganese (Mn): 0.60-0.90%

I-Silicon (Si): 0.10-0.35%

Isibabule (S): ≤ 0.05%

I-Phosphorus (P): ≤ 0.035%

Izakhiwo Zemishini:

Amandla Okudonsa (i-MPa): ≥ 485

Amandla Okukhiqiza (i-MPa): ≥ 205

Ukwelulwa (%): ≥ 20

2. Ibanga F5 - Insimbi Ephansi Yengxubevange

Ukwakheka Kwamakhemikhali:

Ikhabhoni (C): 0.10-0.15%

I-Manganese (Mn): 0.50-0.80%

I-Chromium (Cr): 4.50-5.50%

I-Molybdenum (Mo): 0.90-1.10%

Isibabule (S): ≤ 0.03%

I-Phosphorus (P): ≤ 0.03%

Izakhiwo Zemishini:

Amandla Okudonsa (i-MPa): ≥ 655

Amandla Okukhiqiza (i-MPa): ≥ 345

Ukwelulwa (%): ≥ 20

3. Ibanga F304 - Insimbi Engagqwali Yase-Austenitic

Ukwakheka Kwamakhemikhali:

Ikhabhoni (C): ≤ 0.08%

I-Manganese (Mn): 2.00-2.50%

I-Chromium (Cr): 18.00-20.00%

I-Nickel (Ni): 8.00-10.50%

Isibabule (S): ≤ 0.03%

I-Phosphorus (P): ≤ 0.045%

Izakhiwo Zemishini:

Amandla Okudonsa (i-MPa): ≥ 515

Amandla Okukhiqiza (i-MPa): ≥ 205

Ukwelulwa (%): ≥ 40

4. Ibanga F316 - Insimbi Engagqwali Yase-Austenitic (Emelana Nokugqwala)

Ukwakheka Kwamakhemikhali:

Ikhabhoni (C): ≤ 0.08%

I-Manganese (Mn): 2.00-3.00%

I-Chromium (Cr): 16.00-18.00%

I-Nickel (Ni): 10.00-14.00%

I-Molybdenum (Mo): 2.00-3.00%

Isibabule (S): ≤ 0.03%

I-Phosphorus (P): ≤ 0.045%

Izakhiwo Zemishini:

Amandla Okudonsa (i-MPa): ≥ 515

Amandla Okukhiqiza (i-MPa): ≥ 205

Ukwelulwa (%): ≥ 40

Izakhiwo Zemishini Nezidingo Zomthelela

Izakhiwo zemishini ezifana namandla okudonsa, amandla okukhiqiza, kanye nokwelulwa kubalulekile ekuqinisekiseni ukuthi izingxenye ezibunjiwe zisebenza ngokwethembeka ngaphansi kwengcindezi. I-ASTM A182 icacisa lezi zakhiwo zebanga ngalinye lezinto, kanye nezidingo ezihlukahluka ngokusekelwe ezimweni zokusetshenziswa.

Ukuhlolwa komthelelakungenye ingxenye ebalulekile yendinganiso, okuqinisekisa ukuthi izingxenye ezibunjiwe zingamelana nokushintsha okungazelelwe kwezinga lokushisa noma umthelela. Isibonelo, indinganiso ingadinga ukuhlolwa kwe-Charpy V-notch ukuqinisekisa ukuqina ezimweni zokushisa eziphansi.

Izinqubo Zokukhiqiza Nezidingo Zokwelashwa Kokushisa

I-Womic Steel ilandela izinqubo zokukhiqiza eziqinile ukuqinisekisa ukuthi yonke imikhiqizo ye-ASTM A182 ihlangabezana nezindinganiso zekhwalithi ephezulu. Lokhu kufaka phakathi:

Ukwakha Nokugingqa – Imishini yethu yesimanje iqinisekisa ukuthi ingxenye ngayinye iqinisiwe noma igoqwe ngokulingana okuqondile kanye nokubekezelelana.

Ukwelashwa Kokushisa – Ukwelashwa ngokushisa kubalulekile ekufezeni izakhiwo ezifunwayo zemishini. I-ASTM A182 idinga imijikelezo ethile yokwelashwa ngokushisa kuye ngebanga lezinto ezibonakalayo, njengokunamathisela, ukucima, kanye nokushisa ukuze kuthuthukiswe ukuqina namandla.

Ukushisela – Sihlinzeka ngezixazululo zokushisela ezenziwe ngokwezifiso zemikhiqizo ye-ASTM A182, siqinisekisa ukuxhumana okuthembekile, okuvikela ukuvuza. Izinqubo zokushisela zilawulwa ngokucophelela ukuqinisekisa ukuthi izingxenye ezishiselwe zihlangabezana noma zidlula amandla ezinto eziyisisekelo.

Ukuhlolwa Nokuhlolwa

Senza okubanziukuhlolwa nokuhlolwaukuqinisekisa ukuthi yonke imikhiqizo iyahlangabezana nezindinganiso ze-ASTM A182. Lokhu kufaka phakathi:

Ukuhlolwa Okubonakalayo – Uma kukhona amaphutha noma ukungapheleli ebusweni.

Ukuhlolwa Okungonakalisi (NDT) – Kubandakanya ukuhlolwa kwe-ultrasound kanye nokuhlolwa kwe-x-ray ukuthola amaphutha angaphakathi.

Ukuhlolwa Kwemishini – Amandla okudonseka, amandla okukhiqiza, kanye nokuhlolwa komthelela ukuqinisekisa ukusebenza kwezinto ngaphansi kokucindezeleka.

Ukuhlaziywa Kwamakhemikhali – Ukuqinisekisa ukuthi ukwakheka kwamakhemikhali kunamathela ezimisweni zendinganiso.

Yonke imikhiqizo yethu ilandela izinqubo zokulawula ikhwalithi eziqinile, futhi sinikeza izitifiketi eziningiliziwe zokuthobela yonke i-oda.

Imininingwane Yomkhiqizo kanye Nobubanzi Bosayizi

At Insimbi YaseWomic, sinikeza imikhiqizo ehlukahlukene ye-ASTM A182 ngobukhulu obuhlukahlukene kanye nokucaciswa.ububanzi bosayizikufaka phakathi:

Ama-Flanges: Kusukela ku-1/2" kuya ku-60" ububanzi.

Ukufakwa Okuhlanganisiwe: Kusukela ku-1/2" kuya ku-48" ububanzi.

Amavalvu: Osayizi abangokwezifiso abafanela izidingo zesistimu yakho.

Imikhiqizo yethu itholakala ngezilinganiso zokucindezela ezahlukene kanye nezinto zokwakha, okuqinisekisa ukuthi singahlangabezana nezidingo ezithile zephrojekthi yakho.

Izinzuzo Zokupakisha, Ukuthumela, kanye Nokuthutha

Siyaqonda ukubaluleka kokulethwa ngesikhathi nangokuphepha. I-Womic Steel inikezaukupakishwa okwenziwe ngokwezifisookuvikela ubuqotho bemikhiqizo ngesikhathi sokuthutha. Kungakhathaliseki ukuthi kungokuthunyelwa okunamakhonteyina noma izixazululo ezikhethekile zokuthutha, siyaqinisekisa ukuthi i-oda lakho lifika ngesikhathi futhi lisesimweni esihle.

Okwethuubuchwepheshe bezokuthuthakanye nokubambisana okuqondile nezinkampani zokuthumela kusenza sikwazi ukunikeza amanani okuncintisana kanye nezixazululo zokuthumela eziguquguqukayo.

Ukwenza Ngokwezifiso Nezinsizakalo Ezengeziwe

Ngaphezu kohlu lwethu olubanzi lwemikhiqizo ejwayelekile, i-Womic Steel inikezaukukhiqiza ngokwezifisongezidingo ezihlukile. Singashintsha ubukhulu, izinto zokwakha, kanye nokuqedwa ukuze kuhambisane nesicelo sakho esithile.

Izinsizakalo Zokucubungulafaka:

Umshini - Ukuze uthole ukulungiswa okunembile ukuze kuhambisane nezidingo zakho.

Ukushisela – Ukuxhumeka kwe-flange okwenziwe ngokwezifiso noma ukufakelwa.

Izinsizakalo Zokumboza Nezokuvimbela Ukugqwala – Ukuhlinzeka ngokuvikelwa okuhlala isikhathi eside ngokusekelwe ezidingweni zakho zemvelo.

Kungani Ukhetha Insimbi Yomhlobiso?

Amandla Okukhiqiza: Sinezindawo zokukhiqiza zesimanjemanje ezinamakhono aphezulu okukhiqiza.

Ubuchwepheshe Bobuchwepheshe: Ithimba lethu liqukethe onjiniyela abanekhono eliphezulu kanye nochwepheshe abazinikele ekukhiqizeni imikhiqizo esezingeni eliphezulu.

Inzuzo Yochungechunge Lokunikezela: Sinobudlelwano obuqinile nabaphakeli bezinto zokusetshenziswa, siqinisekisa ukulethwa ngesikhathi kanye nezinzuzo zezindleko.

Izinketho Zokwenza Ngokwezifiso: Sinikeza izixazululo eziguquguqukayo ukuze kuhlangatshezwane nezidingo ezithile zephrojekthi, okuhlanganisa ukushisela, ukugaya, kanye nokufaka ungqimba.

Isiphetho

IIzinga le-ASTM A182iqinisekisa ukuthembeka nokusebenza kahle kwemikhiqizo yensimbi ebunjiwe negoqiwe ezicelweni ezibalulekile. I-Womic Steel ingumlingani wakho othembekile wemikhiqizo esezingeni eliphezulu eyenziwe ngale ndlela, enikeza ukwesekwa okuphelele kusukela ekucacisweni kobuchwepheshe kuya ekuthuthweni kwempahla. Kungakhathaliseki ukuthi udinga osayizi abangokwezifiso, ukushisela, noma ukumbozwa okukhethekile, sinikeza izixazululo ezenzelwe wena ukuze kuhlangatshezwane nezidingo zakho, siqinisekisa ukusebenza okuphezulu kanye nokuthembeka kokulethwa.

Iwebhusayithi: www.womicsteel.com

I-imeyili: sales@womicsteel.com

Ucingo/I-WhatsApp/I-WeChat: Victor: +86-15575100681 noma uJack: +86-18390957568

Isikhathi sokuthunyelwe: Ephreli-21-2025