I-ASME B16.9 vs. I-ASME B16.11: Ukuqhathanisa Okuphelele kanye Nezinzuzo Zokufakwa Kwe-Butt Weld

Siyakwamukela ku-Womic Steel Group!

Uma ukhetha ukufakwa kwamapayipi okusetshenziswa kwezimboni, ukuqonda umehluko obalulekile phakathi kwezindinganiso ze-ASME B16.9 kanye ne-ASME B16.11 kubalulekile. Lesi sihloko sinikeza ukuqhathanisa okuningiliziwe kwalezi zindinganiso ezimbili ezisetshenziswa kabanzi futhi siqokomisa izinzuzo zokufakwa kwamapayipi ezinqeni ezinhlelweni zamapayipi.

Ukuqonda Ukufakwa Kwepayipi

Ukufakwa kwamapayipi kuyisici esisetshenziswa ohlelweni lwamapayipi ukushintsha indlela, ukuxhumeka kwamagatsha, noma ukuguqula ububanzi bamapayipi. Lezi zihlanganisi zihlanganiswa ngomshini ohlelweni futhi zitholakala ngobukhulu obuhlukahlukene kanye namashejuli ukuze zifane namapayipi ahambisanayo.

Izinhlobo Zokufakwa Kwepayipi

Ukufakwa kwamapayipi kuhlukaniswe ngamaqembu amathathu ayinhloko:

Ukufakwa kwe-Butt Weld (BW):Zibuswa yi-ASME B16.9, lezi zihlanganisi zenzelwe ukusetshenziswa kokushisela futhi zifaka izinhlobo ezilula, ezingagqwali ezenziwe ngokwe-MSS SP43.

Ukufakwa kwe-Socket Weld (SW):Njengoba kuchaziwe ngaphansi kwe-ASME B16.11, lezi zihlanganisi zitholakala ngezilinganiso zokucindezela zeKlasi 3000, 6000, kanye ne-9000.

Izinto Zokufaka Ezinentambo (THD):Futhi okuchazwe ku-ASME B16.11, lezi zihlanganisi zihlukaniswe ngaphansi kwezilinganiso ze-Class 2000, 3000, kanye ne-6000.

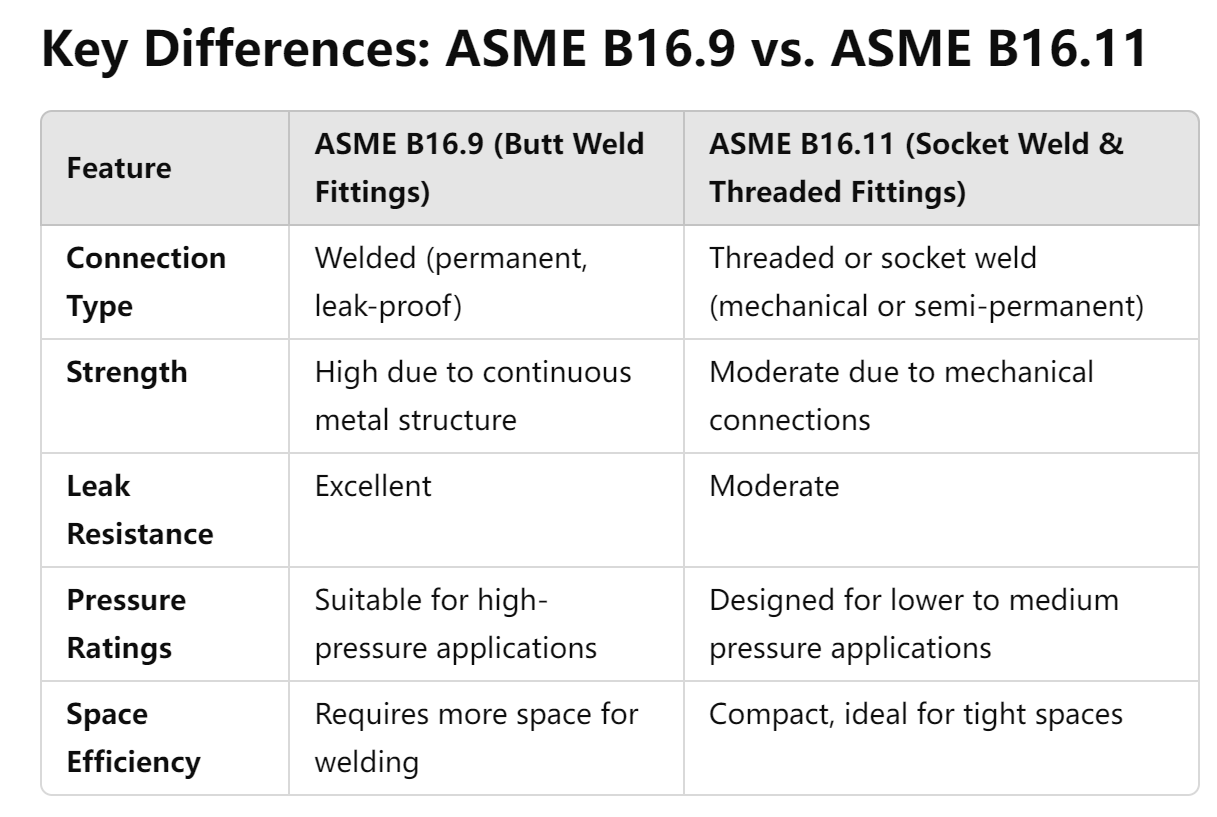

Umehluko Obalulekile: I-ASME B16.9 vs. I-ASME B16.11

Isici

I-ASME B16.9 (Izinto Zokushisela Izinqe)

I-ASME B16.11 (Izihlanganisi Zokushisela Nezintambo)

Uhlobo Lokuxhumeka

Kushiselwe (okuhlala njalo, okuvikela ukuvuza)

Ukushintshwa kwentambo noma kwesokhethi (okwenziwa ngomshini noma okuhlala isikhathi eside)

Amandla

Kuphezulu ngenxa yesakhiwo sensimbi esiqhubekayo

Okumaphakathi ngenxa yokuxhumeka kwemishini

Ukumelana Nokuvuza

Kuhle kakhulu

Okumaphakathi

Izilinganiso Zokucindezela

Ifanele ukusetshenziswa kwengcindezi ephezulu

Yakhelwe izinhlelo zokusebenza eziphansi kuya kweziphakathi

Ukusebenza Kahle Kwesikhala

Kudinga isikhala esengeziwe sokushisela

Incane, ilungele izindawo ezixineneyo

Ukufakwa Okujwayelekile Kwe-Butt Weld Ngaphansi Kwe-ASME B16.9

Okulandelayo yizinto ezijwayelekile zokufaka i-butt weld ezimbozwe yi-ASME B16.9:

I-90° Long Radius (LR) Elbow

I-Endbow Ende Engu-45° (LR)

I-90° Irediyasi Emfushane (SR) Indololwane

I-Elbow Ende Engu-180° (LR)

I-180° Irediyasi Emfushane (SR) Indololwane

I-Equal Tee (EQ)

Ukunciphisa Itiye

I-Concentric Reducer

I-Eccentric Reducer

Isiphetho Sokuphela

I-Stub End ASME B16.9 kanye ne-MSS SP43

Izinzuzo Zokufakwa Kwe-Butt Weld

Ukusebenzisa izinto zokushisela izinqe ohlelweni lwamapayipi kunikeza izinzuzo eziningi:

Amajoyinti Ahlala Njalo, Angavuzi: Ukushisela kuqinisekisa ukuxhumana okuphephile nokuqinile, okususa ukuvuza.

Amandla Esakhiwo Athuthukisiwe: Isakhiwo sensimbi esiqhubekayo phakathi kwepayipi nokufakwa siqinisa amandla esistimu iyonke.

Ubuso Bangaphakathi Obubushelelezi: Kunciphisa ukulahleka kwengcindezi, kunciphisa ukuxokozela, futhi kunciphisa ingozi yokugqwala nokuguguleka.

Incane futhi Yonga Isikhala: Izinhlelo ezihlanganisiwe zidinga isikhala esincane uma kuqhathaniswa nezinye izindlela zokuxhuma.

Iziphetho Ezigobile Zokushisela Okungenamthungo

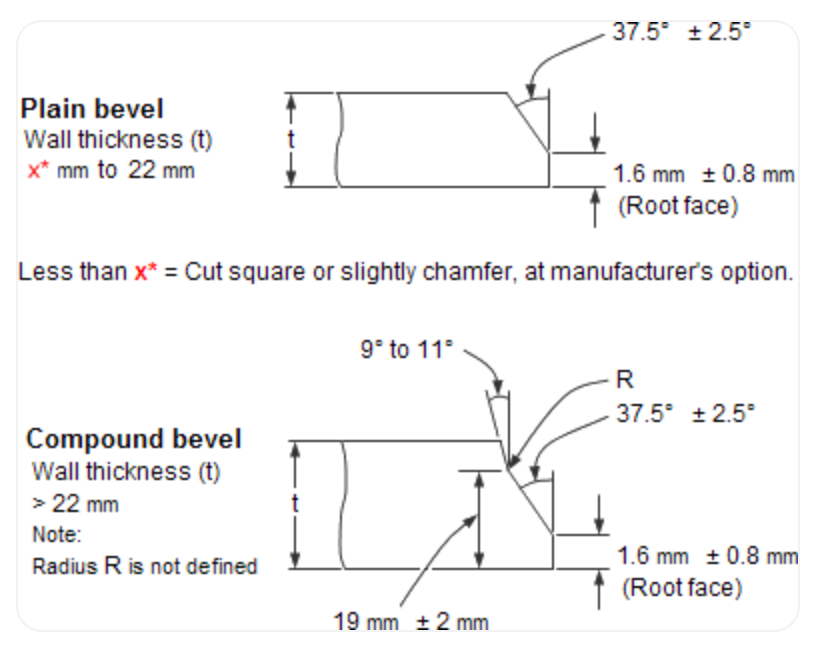

Zonke izinto zokushisela izinqe ziza neziphetho ezigobile ukuze kube lula ukushisela okungenamthungo. Ukushisela kubalulekile ukuqinisekisa amalunga aqinile, ikakhulukazi amapayipi anobukhulu bodonga obudlula:

I-4mm ye-Austenitic Stainless Steel

5mm yensimbi engagqwali ye-Ferritic

I-ASME B16.25 ilawula ukulungiswa kokuxhumeka kwe-buttweld end, iqinisekisa ama-bevel okushisela anembile, ukuma kwangaphandle nangaphakathi, kanye nokubekezelelana okufanele kobukhulu.

Ukukhethwa Kwezinto Zokufaka Amapayipi

Izinto ezivamile ezisetshenziswa ekufakweni kwe-butt weld zifaka:

Insimbi Yekhabhoni

Insimbi engagqwali

Insimbi

I-Aluminium

Ithusi

Ipulasitiki (izinhlobo ezahlukene)

Ukufakwa Okunemigqa: Ukufakwa okukhethekile okunezimbozo zangaphakathi ukuze kusebenze kahle kakhulu ezicelweni ezithile.

Izinto zokuhlanganisa zivame ukukhethwa ukuze zifane nezinto zombhobho ukuqinisekisa ukuhambisana nokuphila isikhathi eside emisebenzini yezimboni.

Mayelana ne-WOMIC STEEL GROUP

I-WOMIC STEEL GROUP ingumholi womhlaba wonke ekukhiqizeni nasekuhlinzekeni ngezinto zokufaka amapayipi ezisezingeni eliphezulu, ama-flange, kanye nezingxenye zamapayipi. Ngokuzibophezela okuqinile ekusunguleni izinto ezintsha, ikhwalithi, kanye nokwaneliseka kwamakhasimende, sinikeza izixazululo ezihamba phambili embonini zemikhakha kawoyela negesi, i-petrochemical, ukukhiqizwa kwamandla, kanye nokwakhiwa. Uhla lwethu oluphelele lwezinto zokufaka ze-ASME B16.9 kanye ne-ASME B16.11 luqinisekisa ukusebenza okuthembekile ezinhlelweni zokusebenza ezidinga kakhulu.

Isiphetho

Uma ukhetha izinto zokufaka amapayipi, ukuqonda umehluko phakathi kwezinto zokufaka i-ASME B16.9 butt weld kanye nezinto zokufaka i-ASME B16.11 socket weld/threaded kubalulekile. Nakuba zombili lezi zindinganiso zisebenza imisebenzi ebalulekile ezinhlelweni zokufaka amapayipi, izinto zokufaka i-butt weld zinikeza amandla aphezulu, ukuxhumana okuvikela ukuvuza, kanye nokuqina okuthuthukisiwe. Ukukhetha izinto zokufaka ezifanele kuzoqinisekisa ukusebenza okuphumelelayo, okuhlala isikhathi eside, nokuphephile ezisetshenziswayo ezimbonini ezahlukahlukene.

Ukuze uthole ukufakwa kwe-ASME B16.9 kanye ne-ASME B16.11 okusezingeni eliphezulu, xhumana nathi namuhla! Sinikeza uhla oluphelele lwezihlanganisi zamapayipi ezenzelwe ukuhlangabezana nezindinganiso eziphakeme kakhulu embonini.

Siyakwamukela ukuxhumana nathi ukuze uthole imininingwane eyengeziwe!

sales@womicsteel.com

Isikhathi sokuthunyelwe: Mashi-20-2025