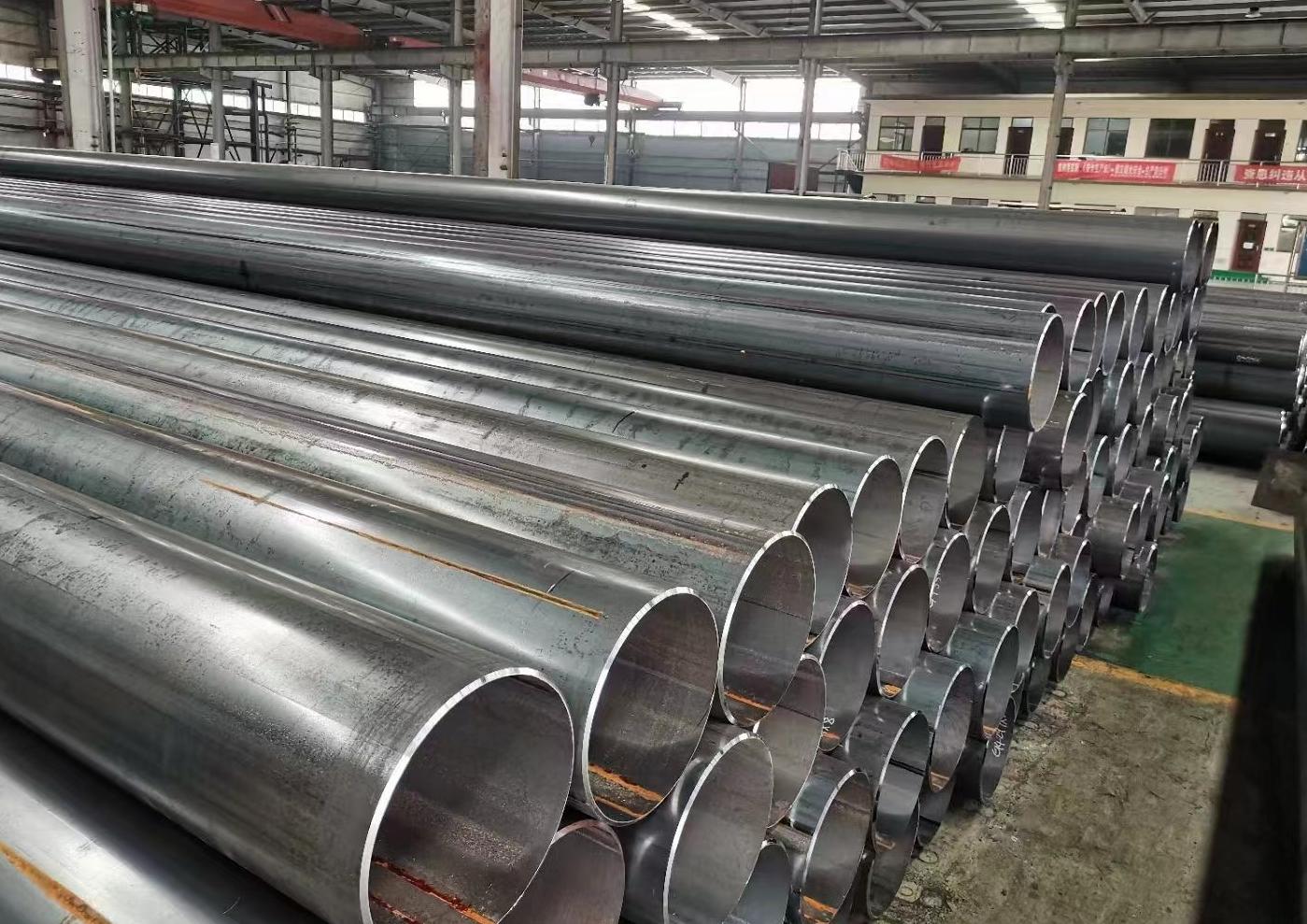

Ukushisela Ukumelana Nogesi, Amapayipi Ensimbi e-ERW akhiqizwa ngokwakhiwa okubandayo kwekhoyili yensimbi ibe yisimo esiyindilinga esiyindilinga.

Amapayipi ensimbi e-ERW, aziwa nangokuthi amapayipi e-ERW ahlanganisiwe, asetshenziswa kabanzi ezimbonini ezahlukene ngenxa yokuguquguquka kwawo nokuqina kwawo. Lawa mapayipi akhiqizwa kusetshenziswa ukushisela kokumelana nogesi, inqubo ehilela ukwakheka kwesimo esiyindilinga esiyindilinga kusuka ku-coil yensimbi. Amaphethelo e-coil yensimbi afudunyezwa kusetshenziswa imisinga kagesi ephansi noma ephezulu ukuze kudalwe ukushisela kwekhwalithi ephezulu.

Ukusetshenziswa kwamapayipi ensimbi e-ERW kubanzi, kusetshenziswa kusukela ku-oyela negesi kuya kumaphrojekthi okwakha kanye nengqalasizinda.

Enye yezindlela ezibalulekile zokusebenzisa amapayipi ensimbi e-ERW ukuthuthwa kukawoyela negesi. Lawa mapayipi asetshenziselwa ukuthutha uwoyela ongahluziwe, igesi yemvelo, neminye imikhiqizo kaphethiloli kusuka ezindaweni zokukhiqiza kuya ezindaweni zokuhluza kanye nezindawo zokusabalalisa. Ama-weld asezingeni eliphezulu emapayipini e-ERW awenza abe ngcono kakhulu ekumelaneni nokucindezela okuphezulu kanye nezimo zemvelo ezinzima, okuqinisekisa ukuthuthwa kukawoyela negesi okuphephile nokuphumelelayo.

Embonini yokwakha, amapayipi ensimbi e-ERW asetshenziselwa izinhlelo ezahlukene zokwakha njengohlaka lwesakhiwo, i-scaffolding, kanye nothango.

Amandla angokwemvelo kanye nokuqina kwala mapayipi kuwenza afanelekele ukusekela imithwalo esindayo kanye nokuhlinzeka ngokusekelwa okubalulekile kwesakhiwo ezakhiweni kanye namaphrojekthi engqalasizinda. Ngaphezu kwalokho, amapayipi e-ERW asetshenziswa futhi ekwakhiweni kwezinhlelo zamanzi kanye nendle, okuqinisekisa ukugeleza kwamanzi kanye nemfucuza okusebenzayo kanye nokusatshalaliswa kahle.

Okunye ukusetshenziswa okubalulekile kwamapayipi ensimbi e-ERW kusekukhiqizweni kwezingxenye zezimoto.

Lawa mapayipi asetshenziswa ekukhiqizweni kwezinhlelo zokukhipha umoya, izingxenye ze-chassis, nezinye izingxenye zezimoto ngenxa yekhono lawo lokubekezelela amazinga okushisa aphezulu kanye nezindawo ezigqwalisayo. Ukunemba kanye nokuvumelana kwe-weld kumapayipi e-ERW kuqinisekisa ukuthembeka nokusebenza kahle kwezinhlelo zezimoto, okufaka isandla ekuphepheni nasekusebenzeni kahle kwezimoto.

Ngaphezu kwalokho, amapayipi ensimbi e-ERW asetshenziswa kakhulu emkhakheni wezolimo ezinhlelweni zokunisela, imishini yokulima, kanye nokwakhiwa kwezindawo zokugcina izithombo. Lawa mapayipi anikeza amandla adingekayo kanye nokumelana nokugqwala, okwenza afaneleke ukusetshenziswa ezindaweni zezolimo ezidinga kakhulu. Ukuguquguquka kwamapayipi e-ERW kudlulela nasembonini yokukhiqiza, lapho asetshenziswa khona ekukhiqizeni imishini, imishini, kanye nezinhlelo zokusebenza ezahlukahlukene zezimboni.

Kwethulwa ama-Precision ERW Steel Tubes, ikhambi elifanele lama-roller kanye nama-conveyor idler tubes ezinhlotsheni ezahlukene zezimboni. Aklanywe ngokunemba nokuqina engqondweni, la ma-tubes aklanywe ukuze asebenze ngaphansi kwezimo ezinzima kakhulu, anikeze ukwesekwa okuthembekile kwezinhlelo zokuhambisa kanye neminye imishini.

Amashubhu ethu ensimbi e-Precision ERW akhiqizwa kusetshenziswa insimbi esezingeni eliphezulu kanye namasu okukhiqiza athuthukile, okuholela kumashubhu aqinile kakhulu futhi amelana nokuguguleka. Lokhu kuwenza abe ukukhetha okuhle kakhulu kwezicelo lapho imithwalo esindayo kanye nokusetshenziswa okuqhubekayo kuvame khona, njengasezimayini, ekwakheni, nasekuphatheni izinto.

Esinye sezici ezibalulekile zama-Precision ERW Steel Tubes ethu ubukhulu bawo obuqondile kanye nokuphela kobuso obubushelelezi. Lokhu kuqinisekisa ukuthi ahambisana kahle nezinye izingxenye, njenge-bearings kanye ne-shafts, okuvumela ukusebenza okungenamthungo futhi kunciphisa ingozi yomonakalo emishinini. Ngaphezu kwalokho, ukuqeda kobuso obubushelelezi kunciphisa ukungqubuzana nokuguguleka kwama-tubes, kwandise isikhathi sawo sokuphila futhi kunciphisa izindleko zokulungisa.

Ngamafuphi, ukusetshenziswa kwamapayipi ensimbi e-ERW kuhlukahlukene futhi kusakazeke kabanzi, kusabalala ezimbonini eziningi kanye nasemikhakha eminingi. Ukushintshwa kwawo kwekhwalithi ephezulu, ukuqina, kanye nokuguquguquka kwenza kube yinto ebalulekile ezinhlotsheni ezahlukene zokusebenza njengokuthuthwa kukawoyela negesi, ukwakhiwa, ukukhiqizwa kwezimoto, ezolimo, kanye nokukhiqiza.

Ngakho-ke, amapayipi ensimbi e-ERW ayaqhubeka nokudlala indima ebalulekile ekusekeleni nasekuthuthukiseni ingqalasizinda yesimanje kanye nentuthuko yezimboni.

Isikhathi sokuthunyelwe: Disemba 15-2023