Isingeniso:

I-API 5L iyincazelo ejwayelekile esungulwe yi-American Petroleum Institute (API) yamapayipi ensimbi angenamthungo nashibilikisiwe asetshenziswa ezinhlelweni zokuhamba ngaphakathi kwezimboni ze-petroleum negesi yemvelo. I-Womic Steel, umkhiqizi ohamba phambili wamapayipi omugqa we-API 5L, inikeza uhla oluphelele lwemikhiqizo ehlangabezana namazinga ahlukahlukene kanye nemininingwane. Lesi sihloko sinikeza ukuqhathanisa okuningiliziwe kokwakheka kwamakhemikhali, izakhiwo zemishini, kanye namazinga okuhlola amamaki ahlukene e-API 5L, kokubili i-PSL1 ne-PSL2 ezinhlotsheni ezintathu zamapayipi: i-ERW (Electric Resistance Welded), i-LSAW (Longitudinal Submerged Arc Welded), kanye ne-SMLS (Seamless).

Amandla Okukhiqiza kanye Nobubanzi:

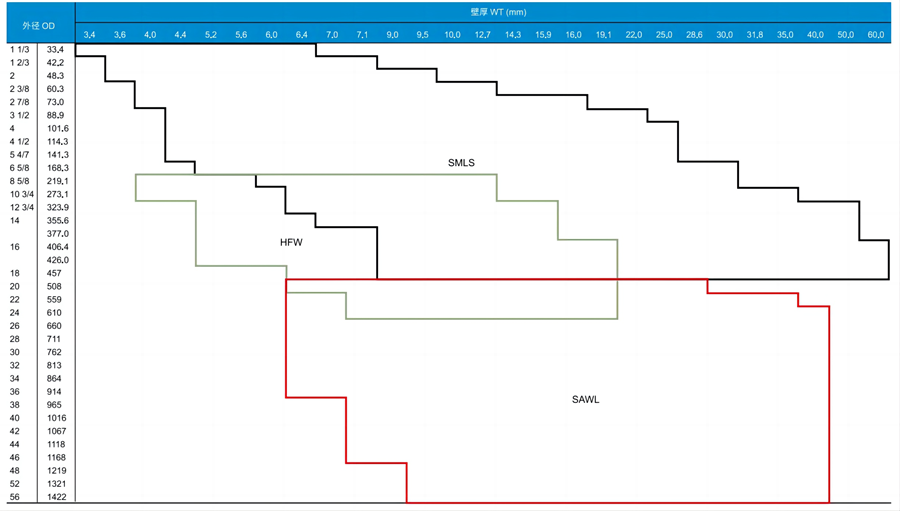

| 制造方法 | 钢级起 | 钢级止 | 外径起 OD Ubuncane mm | 外径止 | 壁厚起 | 壁厚止 | 生产能力 |

| I-SMLS | B | I-X80Q | 33.4 | 457 | 3.4 | 60 | 200000 |

| HFW | B | I-X80M | 219.1 | 610 | 4.0 | 19.1 | 200000 |

| I-SAWL | B | I-X100M | 508 | 1422 | 6.0 | 40 | 500000 |

Ukubekezelela Ububanzi Bangaphandle

| 标准 | 外径范围 | 外径公差 | 椭圆度 | ||||

| 管体 | 管端 | 管体 | 管端 | ||||

| 无缝 | 焊管 | 无缝 | 焊管 | 无缝 | 焊管 | ||

| I-API SPEC SO 3183 | D<60.3mm | +0.4mm/-0.8mm | +1.6mm/-0.4mm | ||||

| 60.3mm≤D≤168.3mm | +0.75%/-0.75% | ≤2.0% | ≤1.5% | ||||

| 168.3mm | +0.5%/-0.5% | ||||||

| 320mm | +1.6mm/-1.6mm | ||||||

| 426mm | +0.75%/-0.75% | +3.2mm/-3.2mm | |||||

| 610mm | +1.0%/-1.0% | +0.5%/-0.5% | ±2.0mm | ±1.6mm | ≤1.5% | ≤1.0% | |

| 800mm | +4mm/-4mm | ||||||

| 1000mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤1.0% | |||

| 1300mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤13mm | |||

Qaphela: U-D ububanzi obujwayelekile bangaphandle bepayipi.

Ukubekezelela Ubukhulu Bodonga

| 标准 | 外径范围 | 壁厚范围 | 壁厚公差 | 壁厚公差 |

| 无缝 | 焊管 | |||

| I-API SPEC I-ISO 3183 | - | t≤4.0mm | +0.6mm/-0.5mm | +0.5mm/-0.5mm |

| - | 4.0mm | +15%/-12.5% | ||

| - | 5.0mm | +10%/-10% | ||

| - | 15.0mmst<25.0mm | +1.5mm/-1.5mm | ||

| - | 25.0mm≤t<30.0mm | +3.7mm/-3.0mm | ||

| - | 30.0mm≤t<37.0mm | +3.7mm/-10.0% | ||

| - | t≥37.0mm | +10.0%/-10.0% |

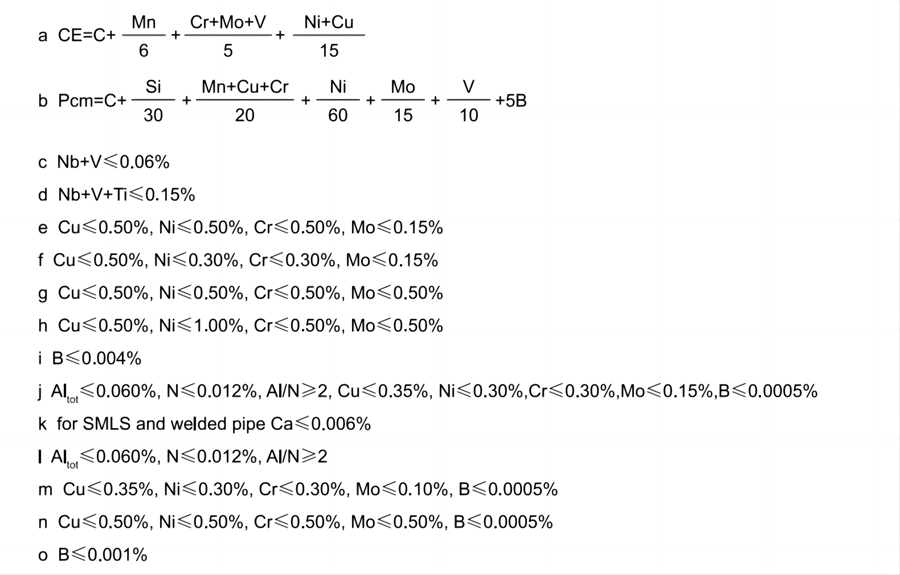

Ukuhlaziywa Kwamakhemikhali

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CE | I-Pcm | 备注 |

| ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | |||||

| I-API SPEC 5L | 无缝管 | I-PSL1 | L210 noma A | 0.22 |

| 0.90 | 0.030 | 0.030 |

|

|

|

|

| e,o |

| L245 noma B | 0.28 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| c,d,e,o | |||

| L290 noma X42 | 0.28 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| I-L320 noma i-X46 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| I-L360 noma i-X52 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| I-L390 noma i-X56 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 noma X60 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 noma X65 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L485 noma X70 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| I-PSL2 | I-L245N noma i-BN | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 |

|

| 0.04 | 0.43 | 0.25 | c,f,o | ||

| L290N noma X42N | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320N noma X46N | 0.24 | 0.40 | 1.40 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L360N noma X52N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L390N noma X56N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415N noma X60N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | Njengoba kuvunyelwene | d,g,o | ||||

| I-L245Q noma i-BQ | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| I-L290Q noma i-X42Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320Q nomaX46Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| 13600 noma ×52Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| I-L390Q noma i-X56Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| I-L415Q noma i-X60Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| I-L450Q noma i-X65Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| I-L485Q noma i-X70Q | 0.18 | 0.45 | 1.80 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| I-L555Q noma i-X80Q | 0.18 | 0.45 | 1.90 | 0.025 | 0.015 |

|

|

| Njengoba kuvunyelwene | h,i | ||||

| 酸性服 | I-L245NS noma i-BNS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 |

|

| 0.04 | 0.36 | 0.22 | c,d,j,k | ||

| I-L290NS noma i-X42NS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | j,k | |||

| I-L320NS noma i-X46NS | 0.14 | 0.40 | 1.40 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | u-dj,k | |||

| I-L360NS noma i-X52NS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,j,k | |||

| I-L245QS noma i-BQS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| I-L290QS noma i-X42QS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| I-L320QS noma i-X46QS | 0.15 | 0.45 | 1.40 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | j,k | |||

| I-L360QS noma i-X52QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,j,k | |||

| I-L390QS noma i-X56QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,j,k | |||

| I-L415QS noma i-X60QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | u-dj,k | |||

| I-L450QS noma i-X65QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| I-L485QS noma i-X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | Ti | I-CEa | I-Pcm | 备注 |

| ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | |||||

| I-AP|SPEC 5L | 无缝管 | 海上服 | L245NO noma i-BNO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 |

|

| 0.04 | 0.36 | 0.22 | c,d,I,m |

| L290NO noma X42NO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | l,m | |||

| L320NO noma X46NO | 0.14 | 0.40 | 1.40 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | d, Mina, m | |||

| L360NO noma X52NO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,I | |||

| I-L245QO noma i-BQO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| I-L290QO noma i-X42Q0 | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| I-L320QO noma i-X46QO | 0.15 | 0.45 | 1.40 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | l,m | |||

| I-L360QO noma i-X52QO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,I,n | |||

| I-L390QO noma i-X56Q0 | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,I,n | |||

| I-L415QO noma i-X60QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | d,I,n | |||

| I-L455QO noma i-X65QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,I,n | |||

| L485Q0 noma X70Q0 | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | 0.42 | 0.25 | d,l,n | |||

| I-L555QO noma i-X80QO | 0.17 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.06 | 0.06 | Njengoba kuvunyelwene | d,I,n | ||||

| 焊管 | I-PSL1 | L245 noma B | 0.26 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| i-cd,e,c | |

| L290 noma i-X42 | 0.26 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L320 noma i-X46 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| I-L360 noma i-X52 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 nomaX56 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 nomaX60 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 noma X65 | 0.26 |

| 1.45 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L485 noma X70 | 0.26 |

| 1.65 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| I-PSL2 | 1245M noma i-BM | 0.22 | 0.45 | 1.20 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | ||

| I-L290M noma i-X42M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| I-L320M noma i-X46M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| I-L360M noma i-X52M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| I-L390M noma i-X56M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L415M noma X60M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| I-L450M noma i-X65M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| I-L485M noma i-X70M | 0.12 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| I-L555M noma i-X80M | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | I-CEa | I-Pcm | 备注 |

| ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | |||||

| I-API SPEC 5L | 焊管 | 酸性服 | I-L245MS noma i-BMS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k |

| I-L290MS noma i-X42MS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k | |||

| I-L320MS noma i-X46MS | 0.10 | 0.45 | 1.35 | 0.020 | 0.002 | 0.05 | 0.05 | 0.04 |

| 0.20 | j,k | |||

| I-L360MS noma i-X52MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.05 | 0.06 | 0.04 |

| 0.20 | j,k | |||

| I-L390MS noma i-X56MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,j,k | |||

| I-L415MS noma i-X60MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,j,k | |||

| I-L450MS noma i-X65MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,j,k | |||

| I-L485MS noma i-X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | u-dj,k | |||

| 海上服 | I-L245MO noma i-BMO | 0.12 | 0.40 | 1.25 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | ||

| I-L290MO noma i-X42MO | 0.12 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | |||

| I-L320MO noma i-X46MO | 0.12 | 0.45 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | Mina, m | |||

| I-L360MO noma i-X52MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | d,I,n | |||

| I-L390MO noma i-X56MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,l,n | |||

| L415MO noma X60MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,I,n | |||

| I-L450MO noma i-X65MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.222 | d,I,n | |||

| L485MO noma X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,l,n | |||

| I-L555MO noma i-X80MO | 0.12 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.24 | d,I,n |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| I-API SPEC 5L | I-PSL1 | L210 noma A | Ubuncane | 210 | 335 | a |

| 335 |

| L245 noma B | Ubuncane | 245 | 415 | a |

| 415 | ||

| L290 noma X42 | Ubuncane | 290 | 415 | a |

| 415 | ||

| I-L320 noma i-X46 | Ubuncane | 320 | 435 | a |

| 435 | ||

| I-L360 noma i-X52 | Ubuncane | 360 | 460 | a |

| 460 | ||

| I-L390 noma i-X56 | Ubuncane | 390 | 490 | a |

| 490 | ||

| L415 noma X60 | Ubuncane | 415 | 520 | a |

| 520 | ||

| L450 noma X65 | Ubuncane | 450 | 535 | a |

| 535 | ||

| L485 noma X70 | Ubuncane | 485 | 570 | a |

| 570 | ||

| I-PSL2 | I-L245N noma i-BN | Ubuncane | 245 | 415 | a |

| 415 | |

| Ubuningi | 450 | 655 |

| 0.93 |

| |||

| L290N noma X42N | Ubuncane | 290 | 415 | a |

| 415 | ||

| Ubuningi | 495 | 655 |

| 0.93 |

| |||

| L320N noma X46N | Ubuncane | 320 | 435 | a |

| 435 | ||

| Ubuningi | 525 | 655 |

| 0.93 |

| |||

| L360N noma X52N | Ubuncane | 360 | 460 | a |

| 460 | ||

| Ubuningi | 530 | 760 |

| 0.93 |

| |||

| L390N noma X56N | Ubuncane | 390 | 490 | a |

| 490 | ||

| Ubuningi | 545 | 760 |

| 0.93 |

| |||

| L415N noma X60N | Ubuncane | 415 | 520 | a |

| 520 | ||

| Ubuningi | 565 | 760 |

| 0.93 |

| |||

| I-L450Q noma i-X65Q | Ubuncane | 450 | 535 | a |

| 535 | ||

| Ubuningi | 600 | 760 |

| 0.93 |

| |||

| I-L485Q noma i-X70Q | Ubuncane | 485 | 570 | a |

| 570 | ||

| Ubuningi | 635 | 760 |

| 0.93 |

| |||

| I-L555Q noma i-X80Q | Ubuncane | 555 | 625 | a |

| 625 | ||

| Ubuningi | 705 | 825 |

| 0.93 |

| |||

| I-L625M noma i-X90M | Ubuncane | 625 | 695 | a |

| 695 | ||

| Ubuningi | 775 | 915 |

| 0.95 |

| |||

| I-L690M noma i-X100M | Ubuncane | 690 | 760 | a |

| 760 | ||

| Ubuningi | 840 | 990 |

| 0.97 |

| |||

| I-L830M noma i-X120M | Ubuncane | 830 | 915 | a |

| 915 | ||

| Ubuningi | 1050 | 1145 |

| 0.99 |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| I-API SPEC 5L | 酸性服 | I-L245NS noma i-BNS | Ubuncane | 245 | 415 | a |

| 415 |

| Ubuningi | 450 | 655 |

| 0.93 |

| |||

| I-L290NS noma i-X42NS | Ubuncane | 290 | 415 | a |

| 415 | ||

| Ubuningi | 495 | 655 |

| 0.93 |

| |||

| I-L320NS noma i-X46NS | Ubuncane | 320 | 435 | a |

| 435 | ||

| Ubuningi | 525 | 655 |

| 0.93 |

| |||

| I-L360NS noma i-X52NS | Ubuncane | 360 | 460 | a |

| 460 | ||

| Ubuningi | 530 | 760 |

| 0.93 |

| |||

| I-L390QS noma i-X56QS | Ubuncane | 390 | 490 | a |

| 490 | ||

| Ubuningi | 545 | 760 |

| 0.93 |

| |||

| I-L415QS noma i-X60QS | Ubuncane | 415 | 520 | a |

| 520 | ||

| Ubuningi | 565 | 760 |

| 0.93 |

| |||

| I-L450QS noma i-X65QS | Ubuncane | 450 | 535 | a |

| 535 | ||

| Ubuningi | 600 | 760 |

| 0.93 |

| |||

| I-L485QS noma i-X70QS | Ubuncane | 485 | 570 | a |

| 570 | ||

| Ubuningi | 635 | 760 |

| 0.93 |

| |||

| 海上服 | L245NO noma i-BNO | Ubuncane | 245 | 415 | a | - | 415 | |

| Ubuningi | 450 | 655 |

| 0.93 |

| |||

| L290NO noma X42NO | Ubuncane | 290 | 415 | a |

| 415 | ||

| Ubuningi | 495 | 655 |

| 0.93 |

| |||

| L320NO noma X46NO | Ubuncane | 320 | 435 | a |

| 435 | ||

| Ubuningi | 520 | 655 |

| 0.93 |

| |||

| L360NO noma X52NO | Ubuncane | 360 | 460 | a |

| 460 | ||

| Ubuningi | 525 | 760 |

| 0.93 |

| |||

| I-L390QO noma i-X56QO | Ubuncane | 390 | 490 | a |

| 490 | ||

| Ubuningi | 540 | 760 |

| 0.93 |

| |||

| I-L415QO noma i-X60QO | Ubuncane | 415 | 520 | a | - | 520 | ||

| Ubuningi | 565 | 760 |

| 0.93 |

| |||

| I-L450QO noma i-X65QO | Ubuncane | 450 | 535 | a | - | 535 | ||

| Ubuningi | 570 | 760 |

| 0.93 |

| |||

| L485Q0 noma X70Q0 | Ubuncane | 485 | 570 | a |

| 570 | ||

| Ubuningi | 605 | 760 |

| 0.93 |

| |||

| I-L555QO noma i-X80QO | Ubuncane | 555 | 625 | a |

| 625 | ||

| Ubuningi | 675 | 825 |

| 0.93 |

Qaphela: a: Ukwelulwa okuncane kusetshenziswa i-equation elandelayo: A1=1940*A0.2/U0.9

| 钢级 | 管体最小横向冲击功(1(2)(3) | 焊缝最小横向冲击功(1(2(3) | |||||

| D≤508 | 508mm | 762mm | 914mm | 1219mm | D<1422mm | D=1422mm | |

| ≤L415 noma X60 | 27(20) | 27(20) | 40(30) | 40(30) | 40(30) | 27(20) | 40(30) |

| >L415 noma X60 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L450 noma X65 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L485 noma X70 | 40(30) | 40(30) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

Qaphela: (1) Amanani asetafuleni afanelekela isampula ejwayelekile yosayizi ogcwele.

(2) Inani elingaphakathi kwebakaki liyinani elilodwa elincane, ibakaki elingaphandle liyinani elimaphakathi.

(3) Izinga Lokushisa Lokuhlola: 0°C.

Izindinganiso Zokuhlola:

Amapayipi omugqa we-API 5L akhiqizwe yi-Womic Steel ahlolwa kanzima ukuqinisekisa ukuthi ahlangabezana nezindinganiso zekhwalithi ephezulu. Izindinganiso zokuhlola zifaka:

Ukuhlaziywa Kwamakhemikhali:

Ukwakheka kwamakhemikhali kwensimbi kuyahlaziywa ukuqinisekisa ukuthi kuyahlangabezana nezidingo zencazelo ye-API 5L.

Ukuhlaziywa kwamakhemikhali kwenziwa kusetshenziswa i-spectrometer yokufunda ngqo ukuze kutholakale ngokunembile ukwakheka kwensimbi.

Ukuhlolwa Kwemishini:

Izakhiwo zemishini ezifana namandla okukhiqiza, amandla okudonsa, kanye nokwelulwa ziyahlolwa ukuqinisekisa ukuthi ziyahlangabezana nezidingo ezibekiwe.

Ukuhlolwa kwemishini kwenziwa kusetshenziswa umshini wokuhlola ukuthambekela ongamathani angu-60 ukukala amandla kanye nokuqina kwensimbi.

Ukuhlolwa Kwamanzi:

Ukuhlolwa kwe-hydrostatic kwenziwa ukuhlola ubuqotho bepayipi nokuqinisekisa ukuthi lingakwazi ukumelana nezidingo zokucindezela zokusetshenziswa kwalo okuhlosiwe.

Amapayipi agcwaliswa ngamanzi futhi acindezelwe, ubude bokuhlolwa kanye namazinga okucindezela achazwe yizindinganiso ze-API 5L.

Ukuhlolwa Okungonakalisi (NDT):

Izindlela ze-NDT ezifana nokuhlolwa kwe-ultrasonic (UT) kanye nokuhlolwa kwezinhlayiya zamagnetic (MT) zisetshenziselwa ukuthola noma yiziphi iziphambeko noma ukungaqhubeki epayipini.

I-UT isetshenziselwa ukuhlonza amaphutha angaphakathi, kanti i-MT isetshenziselwa ukuthola amaphutha angaphezulu.

Ukuhlolwa Komthelela:

Ukuhlolwa komthelela kwenziwa ukuhlola ukuqina kwensimbi emazingeni okushisa aphansi.

Ukuhlolwa komthelela we-Charpy kuvame ukusetshenziselwa ukukala amandla omthelela amuncwa yinsimbi.

Ukuhlolwa Kokuqina:

Ukuhlolwa kokuqina kwenziwa ukuze kuhlolwe ubulukhuni bensimbi, okungabonisa amandla ayo kanye nokufaneleka kwayo ekusetshenzisweni okuthile.

Ukuhlolwa kobulukhuni beRockwell kuvame ukusetshenziselwa ukukala ubulukhuni bensimbi.

Ukuhlolwa kwesakhiwo esincane:

Ukuhlolwa kwesakhiwo esincane kwenziwa ukuze kuhlolwe isakhiwo sezinhlamvu kanye nekhwalithi iyonke yensimbi.

I-microscope yensimbi isetshenziswa ukuhlola isakhiwo sensimbi nokubona noma yikuphi ukukhubazeka.

Ngokunamathela kulezi zindinganiso zokuhlola eziqinile, i-Womic Steel iqinisekisa ukuthi amapayipi ayo omugqa we-API 5L ahlangabezana nezidingo zekhwalithi ephezulu futhi ahlinzeka ngokusebenza okuthembekile ezinhlotsheni ezahlukahlukene zezimboni.

Inqubo Yokukhiqiza:

1. Amapayipi Ensimbi Angenamthungo:

- Ukukhethwa Kwezinto Ezingavuthiwe: Ama-billet ensimbi ayindilinga asezingeni eliphezulu akhethwa ukuze kukhiqizwe amapayipi ensimbi angenamthungo.

- Ukushisa Nokubhoboza: Ama-billet ashiswa kuze kufike ekushiseni okuphezulu bese ebhobozwa ukuze kwakheke igobolondo elingenalutho.

- Ukugoqa Nokulinganisa: Igobolondo elibhoboziwe liyagoqwa bese lelulwa libe ububanzi nobukhulu obufunayo.

- Ukwelashwa Kokushisa: Amapayipi afakwa ezinqubweni zokwelashwa kokushisa njengokufakwa kwe-anneal noma ukwenziwa abe ngokwejwayelekile ukuze kuthuthukiswe izakhiwo zawo zemishini.

- Ukuqeda: Amapayipi adlula ezinqubweni zokuqeda ezifana nokuqondisa, ukusika, kanye nokuhlolwa.

- Ukuhlolwa: Amapayipi adlula ezivivinyweni ezahlukahlukene, okuhlanganisa ukuhlolwa kwe-hydrostatic, ukuhlolwa kwe-ultrasonic, kanye nokuhlolwa kwe-eddy current, ukuqinisekisa ikhwalithi yawo.

- Ukwelashwa Komphezulu: Amapayipi angase ambozwe noma aphathwe ukuze kuvinjelwe ukugqwala futhi kuthuthukiswe ukubukeka kwawo.

- Ukupakishwa Nokuthunyelwa: Amapayipi apakishwa ngokucophelela futhi athunyelwa kumakhasimende.

2. Amapayipi Ensimbi e-LSAW (Longitudinal Submerged Arc Welding):

- Ukulungiswa Kwepuleti: Amapuleti ensimbi asezingeni eliphezulu alungiselelwa ukukhiqizwa kwamapayipi e-LSAW.

- Ukwakheka: Amapuleti akhiwa abe yisimo "sika-U" kusetshenziswa umshini wokugoba ngaphambi kokufakwa.

- Ukushisela: Amapuleti anomumo "U" abe eseshisela ndawonye kusetshenziswa inqubo yokushisela ye-arc engaphansi kwamanzi.

- Ukwandiswa: Umthungo ohlanganisiwe unwetshwa ube ububanzi obufunekayo kusetshenziswa umshini wokwandisa wangaphakathi noma wangaphandle.

- Ukuhlolwa: Amapayipi ayahlolwa ukuze kutholakale amaphutha kanye nokunemba kobukhulu bawo.

- Ukuhlolwa kwe-Ultrasonic: Amapayipi ahlolwa nge-ultrasound ukuthola noma yiziphi izinkinga zangaphakathi.

- Ukugoba: Iziphetho zamapayipi zigoba ukuze zishiselwe.

- Ukufaka Umbala Nokumaka: Amapayipi angafakwa upende futhi amakwe ngokwezidingo zamakhasimende.

- Ukupakishwa Nokuthunyelwa: Amapayipi ayapakishwa futhi athunyelwe kumakhasimende.

3. Amapayipi Ensimbi e-HFW (Ukushisela Okuvame Kakhulu):

- Ukulungiswa Kwekhoyili: Amakhoyili ensimbi alungiselelwa ukukhiqizwa kwamapayipi e-HFW.

- Ukwakheka Nokushisela: Amakhoyili akhiwa abe yisimo esiyindilinga bese eshiselwa kusetshenziswa ukushisela okuvamise kakhulu.

- Ukushisa Komphetho Wokushisela: Umphetho wokushisela ushiswa ufike ezingeni lokushisa lokushisela kusetshenziswa ukushisa kokungeniswa okuvama kakhulu.

- Usayizi: Ipayipi elihlanganisiwe lilingana nobubanzi nobukhulu obudingekayo.

- Ukusika Nokugoba: Ipayipi lisikwa libe nobude obufunekayo futhi iziphetho ziyagoba ukuze kushiselwe.

- Ukuhlolwa: Amapayipi ayahlolwa ukuze kutholakale amaphutha kanye nokunemba kobukhulu bawo.

- Ukuhlolwa Kwamanzi: Amapayipi ahlolwa amandla nokuvuza kusetshenziswa ukuhlolwa kwe-hydrostatic.

- Ukufaka Umbala Nokumaka: Amapayipi ambozwe futhi amakwe ngokwezidingo zamakhasimende.

- Ukupakishwa Nokuthunyelwa: Amapayipi ayapakishwa futhi athunyelwe kumakhasimende.

Lezi zinqubo zokukhiqiza ezinemininingwane ziqinisekisa ikhwalithi ephezulu kanye nokuthembeka kwamapayipi ensimbi angenamthungo, i-LSAW, kanye ne-HFW akhiqizwa yi-Womic Steel, ahlangabezana nezidingo eziqinile zezimboni ezahlukahlukene.

Ukwelashwa Okuphezulu:

Ukwelashwa kobuso bensimbi yamapayipi kubalulekile ekuthuthukiseni ukumelana kwayo nokugqwala kanye nokuphila kwayo kwenkonzo. I-Womic Steel isebenzisa izindlela ezahlukene zokwelapha ubuso kuncike ezidingweni ezahlukene ezivela kumakhasimende, okuhlanganisa:

1. I-Hot-dip Galvanizing: Ipayipi lensimbi licwiliswa ku-zinc encibilikisiwe ukuze kwakheke ungqimba oluvikelayo lwe-zinc-iron alloy, okwandisa ukumelana kwayo nokugqwala. I-hot-dip galvanizing ifaneleka kumapayipi avamile nanomfutho ophansi.

2. Izembozo Ezingagqwali: Izembozo ezivamile ezilwa nokugqwala zifaka phakathi izembozo ze-epoxy, izembozo ze-polyethylene, kanye nezembozo ze-polyurethane. Lezi zembozo zivimbela ngempumelelo ukugqwala nokugqwala ebusweni bepayipi lensimbi, zandise isikhathi sayo sokusebenza.

3. Ukuqhumisa ngesihlabathi: Ukuqhumisa ngesihlabathi okusheshayo kusetshenziselwa ukuhlanza ipayipi lensimbi, ukususa ukugqwala nokungcola ebusweni, okuhlinzeka ngesisekelo esihle sokwelashwa kokumboza okulandelayo.

4. Ukwelashwa Kokumboza: Ubuso bepayipi lensimbi bungambozwa ngopende oluvimbela ukugqwala, upende we-asphalt, nezinye izinto zokumboza ukuze kuthuthukiswe ukumelana nokugqwala, ezifanele amapayipi angaphansi komhlaba kanye namapayipi ezindaweni zasolwandle.

Lezi zindlela zokwelapha ubuso zivikela ngempumelelo insimbi yamapayipi ekugqwaleni nasekulimaleni, ziqinisekisa ukuthembeka kwayo nokuqina kwayo ezindaweni ezahlukahlukene ezinzima.

Ukupakisha Nokuthutha:

I-Womic Steel iqinisekisa ukupakishwa okuphephile kanye nokuthuthwa okuthembekile kwensimbi yamapayipi, inikeza izinketho eziguquguqukayo zokuhlangabezana nezidingo zamakhasimende ezahlukahlukene:

1. Imithwalo Emikhulu: Uma ku-oda elikhulu, insimbi yamapayipi ingathunyelwa ngobuningi kusetshenziswa izithwali zemithwalo ezikhethekile. Insimbi ilayishwa ngqo endaweni yokugcina umkhumbi ngaphandle kokupakishwa, ifanele ukuthuthwa ngobuningi obukhulu ngendlela engabizi kakhulu.

2. I-LCL (Umthwalo Ongaphansi Kwesitsha): Kuma-oda amancane, insimbi yepayipi ingathunyelwa njengempahla ye-LCL, lapho ama-oda amaningi amancane ehlanganiswa khona esitsheni esisodwa. Le ndlela ingabizi kakhulu ngamanani amancane futhi inikeza amashejuli okulethwa aguquguqukayo.

3. I-FCL (Umthwalo Ogcwele Wesitsha): Amakhasimende angakhetha ukuthunyelwa kwe-FCL, lapho isitsha esigcwele sinikezelwe khona ku-oda lawo. Le ndlela inikeza izikhathi zokuthutha ezisheshayo futhi inciphisa ingozi yomonakalo ngesikhathi sokuphathwa.

4. Ukuthutha Ngendiza: Uma ku-oda okuphuthumayo, ukuthutha ngendiza kuyatholakala ukuze kulethwe ngokushesha. Nakuba kubiza kakhulu kunempahla yolwandle, ukuthutha ngendiza kunikeza ukuthutha okusheshayo nokuthembekile kokuthunyelwa okubucayi ngesikhathi.

I-Womic Steel iqinisekisa ukuthi konke ukuthunyelwa kupakishwe kahle ukuze kuvinjelwe umonakalo ngesikhathi sokuthuthwa. Insimbi ivame ukugoqwa ngezinto zokuzivikela bese ivalwa ezitsheni noma emaphalethini ukuqinisekisa ukuzinza ngesikhathi sokuthuthwa. Ngaphezu kwalokho, inkampani isebenzisana eduze nabalingani bokuthutha abathembekile ukuqinisekisa ukulethwa ngesikhathi kanye nokuphathwa kwempahla okuphumelelayo.

Izimo Zokusebenza:

Amapayipi omugqa we-API 5L akhiqizwa yi-Womic Steel asetshenziswa kabanzi embonini kaphethiloli kanye negesi yemvelo ukuze kuthuthwe uwoyela, igesi, kanye nolunye uketshezi. Asetshenziswa nakwezinye izimboni ezahlukahlukene njengokucubungula amakhemikhali, ukukhiqizwa kwamandla, kanye nokwakha.

Isiphetho:

I-Womic Steel ingumkhiqizi othembekile wamapayipi omugqa we-API 5L, enikeza imikhiqizo esezingeni eliphezulu ehlangabezana nezidingo eziqinile zezimboni zephethiloli negesi yemvelo. Ngokugxila ekhwalithini, ukuthembeka, kanye nokwaneliseka kwamakhasimende, i-Womic Steel iyaqhubeka nokuba ukukhetha okuthandwayo kumakhasimende emhlabeni jikelele.

Isikhathi sokuthunyelwe: Mashi-22-2024