Amapayipi ngokuya ngokusetshenziswa kanye nezinto zombhobho, izindlela zokuxhuma ezivame ukusetshenziswa yilezi: uxhumano olunezintambo, uxhumano lwe-flange, ukushisela, uxhumano lwe-groove (uxhumano lwe-clamp), uxhumano lwe-ferrule, uxhumano lwe-card pressure, uxhumano olushisayo lokuncibilika, uxhumano lwe-socket njalo njalo.

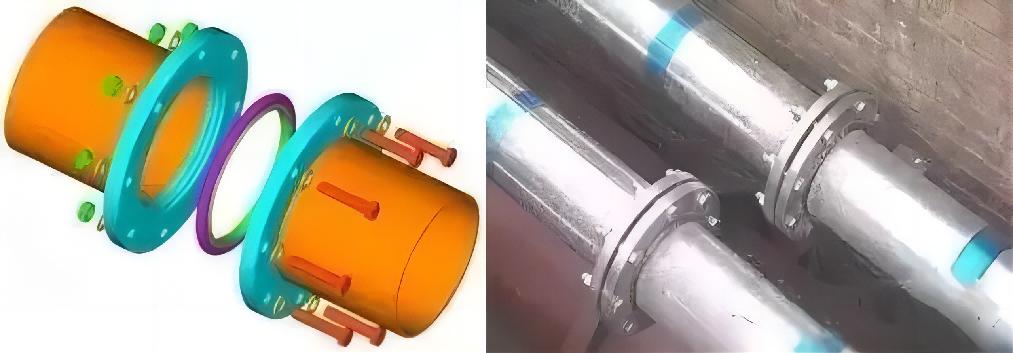

1. Uxhumano lweFlange

Amapayipi amakhulu anobubanzi axhunywe ngama-flange, futhi ukuxhumeka kwe-flange kuvame ukusetshenziswa kuma-valve okuxhuma ayinhloko, ama-valve okuhlola, amamitha amanzi, amaphampu, njll., kanye nesidingo sokuhlukaniswa njalo nokugcinwa kwengxenye yepayipi. Amapayipi e-galvanized afana nokushisela noma ukuxhumeka kwe-flange, ukushisela kufanele kube yi-galvanized yesibili noma ukugqwala.

2. Ukushisela

Ukushisela kusebenza kumapayipi ensimbi angagayiwe nge-galvanized, asetshenziswa kakhulu ekushiseni amapayipi afihliwe kanye namapayipi amakhulu, kanye nokusetshenziswa okwengeziwe ezakhiweni eziphakeme. Ukuxhumeka kwamapayipi ethusi kungasebenzisa amalunga akhethekile noma ukushisisa, lapho ububanzi bepayipi bungaphansi kwama-socket angu-22mm noma ukushisisa kwekhava kufanelekile, isokhethi kufanele ihlangabezane nesiqondiso sokugeleza kwemidiya ukufakwa, lapho ububanzi bepayipi bukhulu noma bulingana nama-22mm kufanelekile ukusebenzisa ukushisisa kwe-butt. Ipayipi lensimbi engagqwali lingaba ukushisisa kwe-socket.

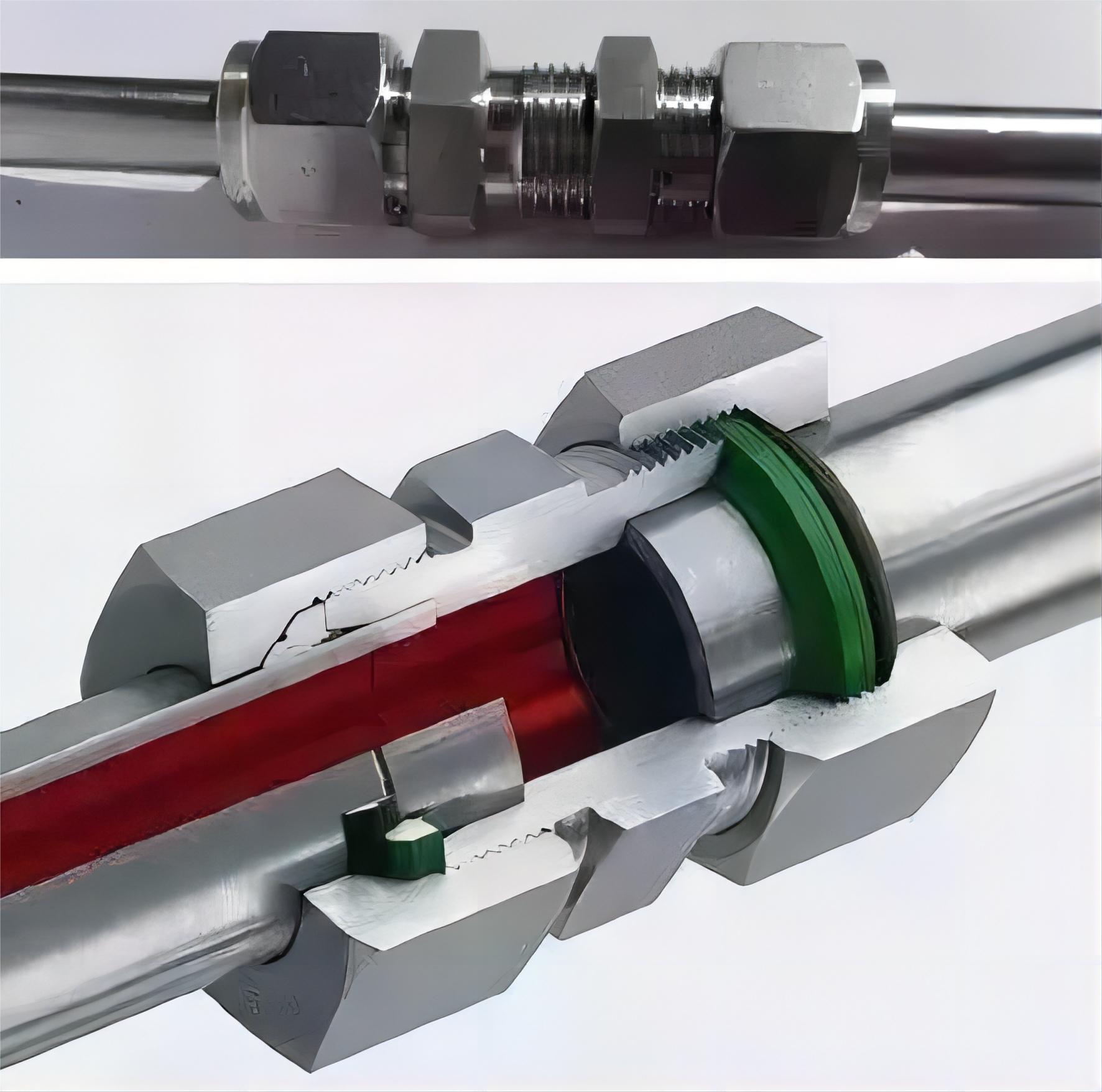

3. Uxhumano Lwesikulufu

Ukuxhumeka okunentambo kusetshenziswa izihlanganisi zamapayipi ezinokuxhumeka okunentambo, ububanzi bepayipi obungaphansi noma obulingana no-100mm wepayipi lensimbi elihlanganisiwe kufanele kube nokuxhumeka okunentambo, okusetshenziselwa kakhulu ipayipi elivulekile. Ipayipi elihlanganisiwe lensimbi-ipulasitiki ngokuvamile lisetshenziswa futhi nokuxhumeka okunentambo. Ipayipi lensimbi elihlanganisiwe kufanele kube nokuxhumeka okunentambo, isethi yebhande lesilika lapho kubhujiswa ubuso bengqimba elihlanganisiwe kanye nengxenye ehlanganisiwe eveziwe kufanele kwenziwe ukuvimbela ukugqwala; kufanele kusetshenziswe izihlanganisi ezikhethekile zohlobo lwe-flange noma lwe-ferrule ukuxhuma ipayipi lensimbi elihlanganisiwe kanye ne-flange ye-weld kufanele ihlanganiswe okwesibili.

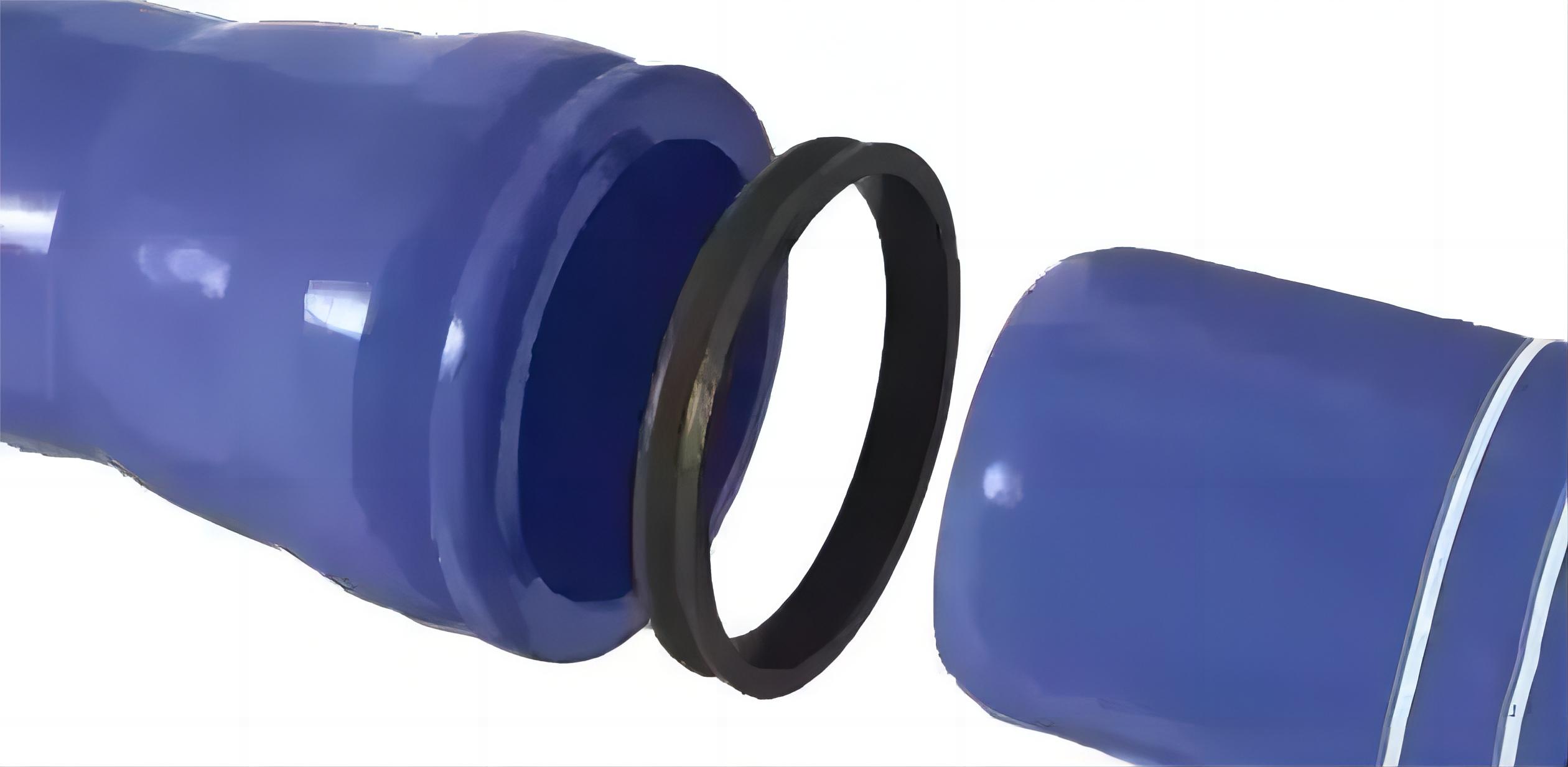

4. Uxhumano lweSocket

Isetshenziselwa ukuhlinzeka ngamanzi kanye nokuxhumanisa ipayipi lensimbi ephonswe kanye nokufakwa kwamapayipi. Kunezinhlobo ezimbili zokuxhuma okuguquguqukayo kanye nokuxhuma okuqinile, ukuxhumana okuguquguqukayo kuvalwe ngamasongo erabha, ukuxhumana okuqinile kuvalwe ngesamente se-asbestos noma ama-filler amakhulu, kanye nezimpawu zomthofu ziyatholakala emicimbini ebalulekile.

5.FiphuthaCukuxhumana

Amapayipi e-aluminium-plastic ahlanganisiwe ngokuvamile aboshwe ngezintambo ezifakwe izintambo. Izinto ezifakwayo zinamathela ekugcineni kwepayipi, bese izinto ezifakwayo zingena ekugcineni, nge-wrench yokuqinisa izinto ezifakwayo namantongomane kungaba. Ukuxhumeka kwepayipi lethusi kungasetshenziswa futhi ngezintambo ezifakwa izintambo ezifakwe izintambo.

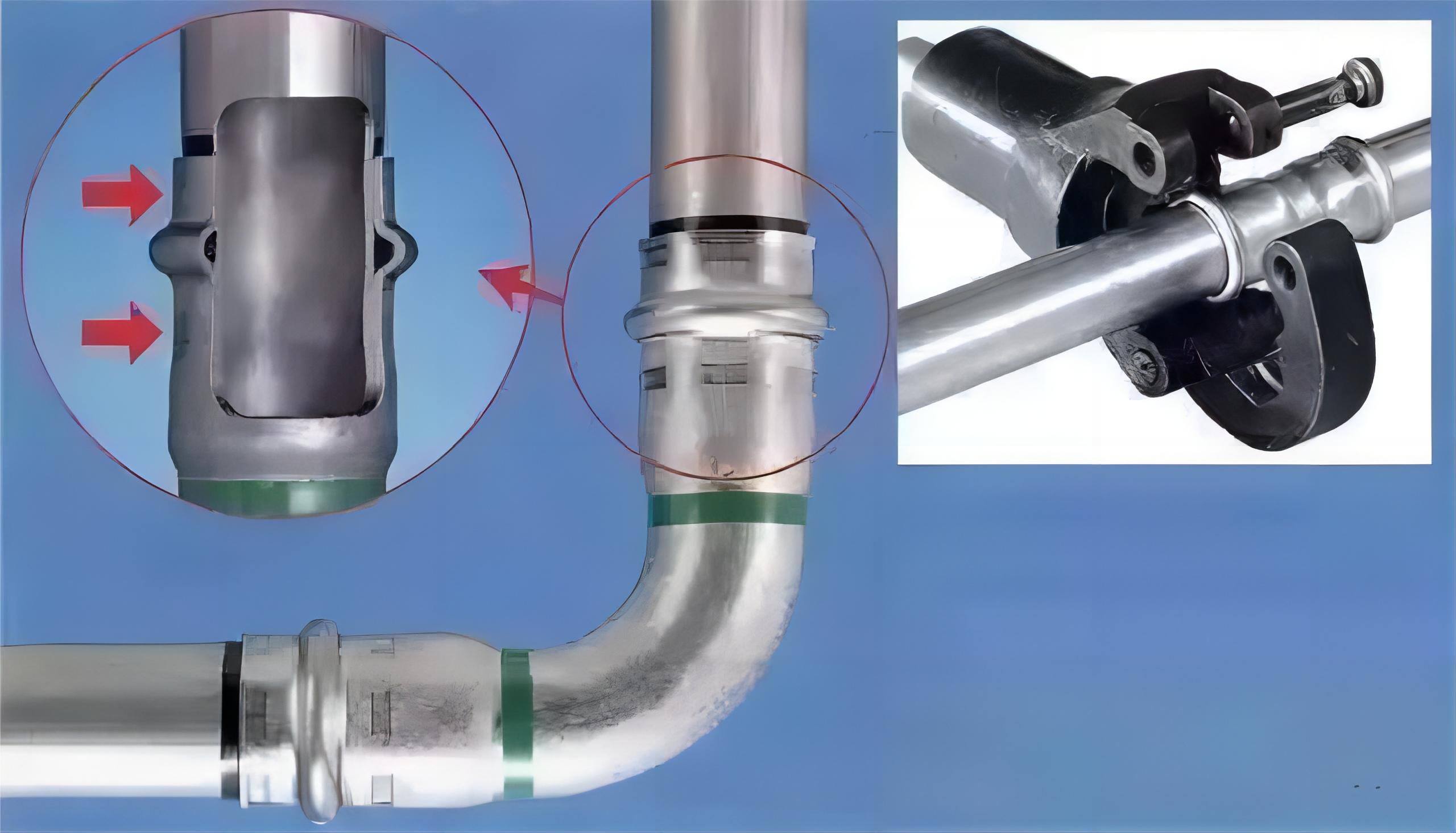

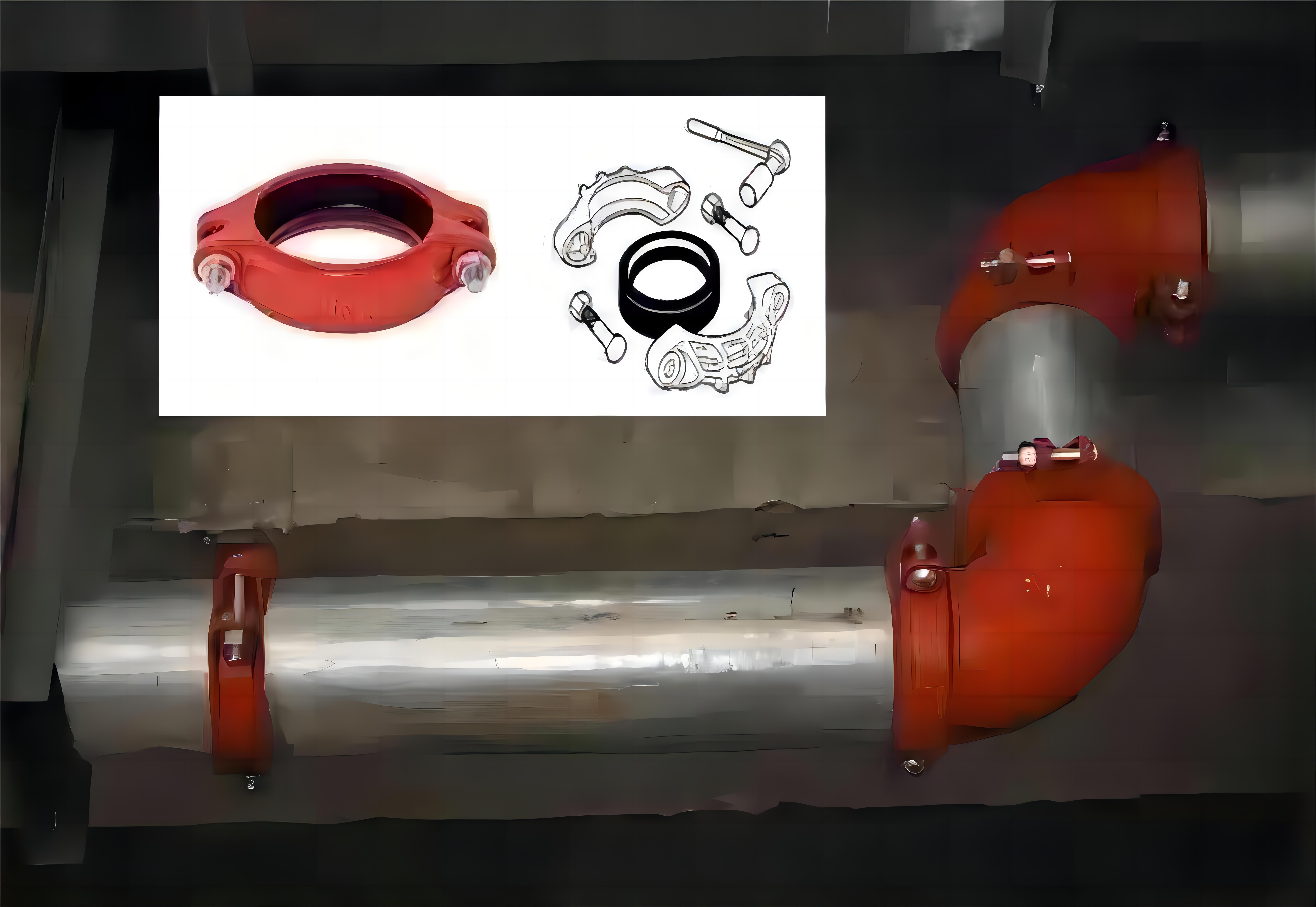

6. Ukuxhumeka kwe-Clamp

Ubuchwepheshe bokuxhumanisa izinto zokucindezela zensimbi engagqwali ukuze kuthathelwe indawo ubuchwepheshe bokuxhumanisa amapayipi amanzi ahlanganisiwe, ahlanganisiwe, anamathiselwe kanye nobunye ubuchwepheshe bendabuko bokuxhumanisa amapayipi, ngokuvikelwa kokuhlanzeka kwamanzi, ukumelana nokugqwala, impilo yenkonzo ende njalo njalo, ukwakhiwa kwendandatho yokuvala ekhethekile enezihlanganisi ezikhethekile zesokhethi kanye nokuxhumeka kwepayipi, ukusetshenziswa kwamathuluzi akhethekile ukuqinisa umlomo wepayipi ukuze kudlale umphumela wokuvala nokuqinisa, ukwakhiwa kokufakwa kulula, kuthembekile futhi kunengqondo ngokwezomnotho kanye nezinye izinzuzo.

7. Uxhumano lwe-Hotmelt

Indlela yokuxhuma yepayipi le-PPR ukuxhumana kokuhlanganiswa kokushisa ngedivayisi yokuhlanganiswa kokushisa.

8. I-Groove Connect

Isikhathi sokuthunyelwe: Novemba-06-2023