Incazelo Yomkhiqizo

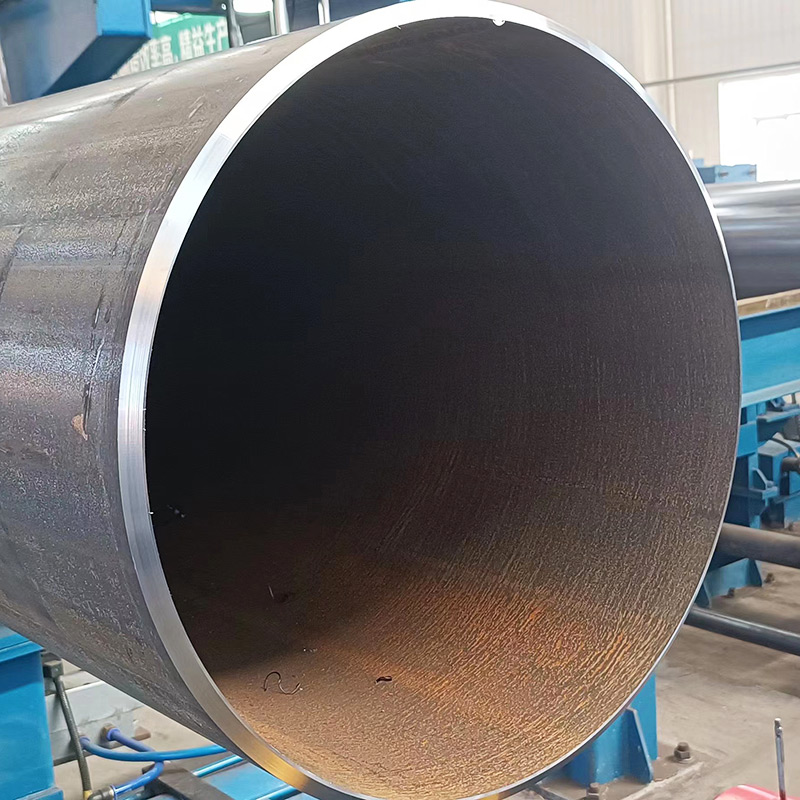

Amapayipi ensimbi e-LSAW (Longitudinal Submerged Arc Welding) awuhlobo lwepayipi lensimbi elihlanganisiwe elibonakala ngenqubo yalo yokukhiqiza eyingqayizivele kanye nohlu olubanzi lwezicelo. Lawa mapayipi akhiqizwa ngokwenza ipuleti lensimbi libe yisimo esiyindilinga bese lihlanganiswa ngobude kusetshenziswa amasu okushisela e-arc angaphansi komhlaba. Nasi isifinyezo samapayipi ensimbi e-LSAW:

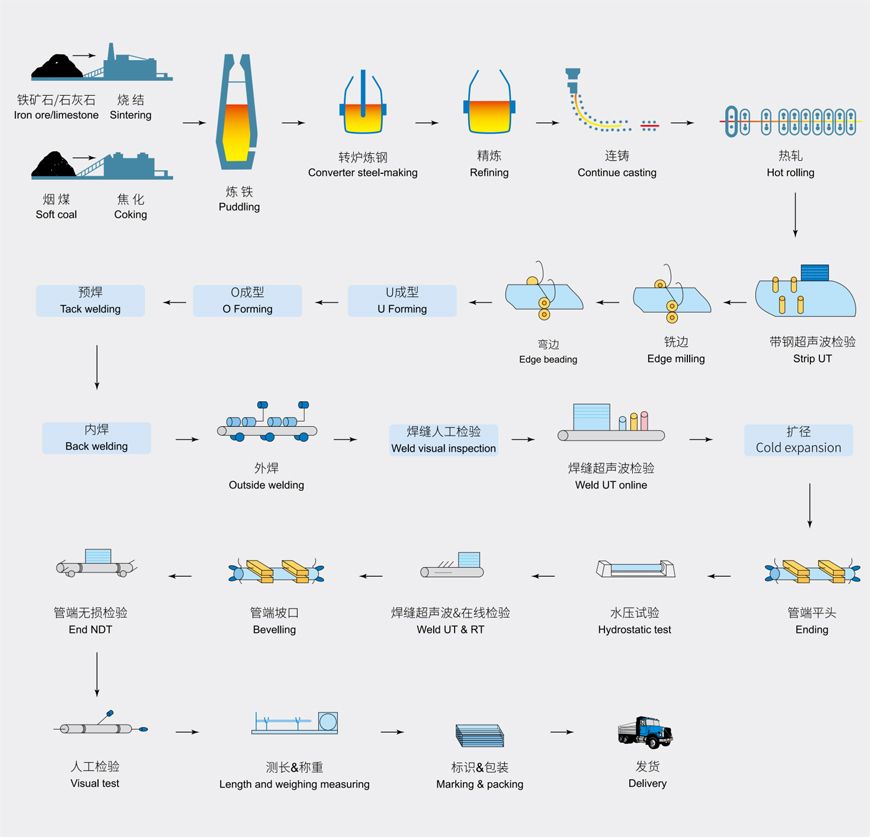

Inqubo Yokukhiqiza:

● Ukulungiswa Kwepuleti: Amapuleti ensimbi asezingeni eliphezulu akhethwa ngokusekelwe ezidingweni ezithile, okuqinisekisa izakhiwo zemishini ezifiselekayo kanye nokwakheka kwamakhemikhali.

● Ukwakheka: Ipuleti lensimbi libunjwe libe yipayipi eliyindilinga ngezinqubo ezifana nokugoba, ukugoqa, noma ukucindezela (i-JCOE ne-UOE). Amaphethelo agobile kusengaphambili ukuze kube lula ukushisela.

● Ukushisela: Kusetshenziswa ukushisela kwe-arc ecmerged (SAW), lapho i-arc igcinwa khona ngaphansi kwesendlalelo se-flux. Lokhu kukhiqiza ukushisela kwekhwalithi ephezulu okunamaphutha amancane kanye nokuhlanganiswa okuhle kakhulu.

● Ukuhlolwa kwe-Ultrasonic: Ngemva kokushisela, kwenziwa ukuhlolwa kwe-ultrasound ukuthola noma yiziphi iziphambeko zangaphakathi noma zangaphandle endaweni yokushisela.

● Ukwandisa: Ipayipi lingandiswa ukuze kufezwe ububanzi obufunekayo kanye nobukhulu bodonga, okuthuthukisa ukunemba kobukhulu.

● Ukuhlolwa Kokugcina: Ukuhlolwa okuphelele, okuhlanganisa ukuhlolwa okubonakalayo, ukuhlolwa kobukhulu, kanye nokuhlolwa kwempahla yemishini, kuqinisekisa ikhwalithi yepayipi.

Izinzuzo:

● Ukonga Izindleko: Amapayipi e-LSAW anikeza ikhambi elingabizi kakhulu lamapayipi amakhulu kanye nezicelo zesakhiwo ngenxa yenqubo yawo yokukhiqiza ephumelelayo.

● Amandla Aphezulu: Indlela yokushisela ende iholela emapayipini anezakhiwo eziqinile nezifanayo zemishini.

● Ukunemba Kobukhulu: Amapayipi e-LSAW abonisa ubukhulu obuqondile, okwenza afaneleke ukusetshenziswa ngokubekezelelana okuqinile.

● Ikhwalithi Yokushisela: Ukushisela kwe-arc okucwiliswe emanzini kukhiqiza ukushisela kwekhwalithi ephezulu okunokuhlanganiswa okuhle kakhulu kanye namaphutha amancane.

● Ukuguquguquka: Amapayipi e-LSAW asetshenziswa ezimbonini ezahlukahlukene, okuhlanganisa uwoyela negesi, ukwakhiwa, kanye nokuhlinzekwa kwamanzi, ngenxa yokuzivumelanisa nezimo nokuqina kwawo.

Ngamafuphi, amapayipi ensimbi e-LSAW akhiqizwa kusetshenziswa inqubo enembile nephumelelayo, okuholela kumapayipi aguquguqukayo, angabizi kakhulu, futhi ahlala isikhathi eside afanelekela ukusetshenziswa okubanzi kwezimboni.

Imininingwane

| I-API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| I-ASTM A252: GR.1, GR.2, GR.3 |

| I-EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-ASTM A53/A53M: GR.A, GR.B |

| I-EN 10217: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| I-DIN 2458: St37.0, St44.0, St52.0 |

| I-AS/NZS 1163: Ibanga C250 , Ibanga C350, Ibanga C450 |

| I-GB/T 9711: L175, L210, L245, L290, L320, L360, L390, L415, L450, L485 |

| I-ASTMA671: CA55/CB70/CC65, CB60/CB65/CB70/CC60/CC70, CD70/CE55/CE65/CF65/CF70, CF66/CF71/CF72/CF73, CG100/CH100/CI100/CJ100 |

Uhla Lokukhiqiza

| Ububanzi Bangaphandle | Ukujiya kodonga okutholakalayo kwebanga elingaphansi kwensimbi | |||||||

| Intshi | mm | Ibanga Lensimbi | ||||||

| Intshi | mm | L245(Gr.B) | L290(X42) | L360(X52) | L415(X60) | L450(X65) | L485(X70) | L555(X80) |

| 16 | 406 | 6.0-50.0mm | 6.0-48.0mm | 6.0-48.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 18 | 457 | 6.0-50.0mm | 6.0-48.0mm | 6.0-48.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 20 | 508 | 6.0-50.0mm | 6.0-50.0mm | 6.0-50.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 22 | 559 | 6.0-50.0mm | 6.0-50.0mm | 6.0-50.0mm | 6.0-45.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 24 | 610 | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-45.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 26 | 660 | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-48.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 28 | 711 | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-48.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 30 | 762 | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 32 | 813 | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 34 | 864 | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 36 | 914 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 38 | 965 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 40 | 1016 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 42 | 1067 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 44 | 1118 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 46 | 1168 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 48 | 1219 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 52 | 1321 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 56 | 1422 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 60 | 1524 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 64 | 1626 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 68 | 1727 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 72 | 1829 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

* Okunye Usayizi kungenziwa ngezifiso ngemuva kwengxoxo

Ukwakheka Kwamakhemikhali Nezakhiwo Zemishini Zepayipi Lensimbi le-LSAW

| Okujwayelekile | Ibanga | Ukwakheka Kwamakhemikhali (ubuningi)% | Izakhiwo Zemishini (iminithi) | |||||

| C | Mn | Si | S | P | Amandla Okukhiqiza (i-Mpa) | Amandla Okudonsa (i-Mpa) | ||

| GB/T700-2006 | A | 0.22 | 1.4 | 0.35 | 0.050 | 0.045 | 235 | 370 |

| B | 0.2 | 1.4 | 0.35 | 0.045 | 0.045 | 235 | 370 | |

| C | 0.17 | 1.4 | 0.35 | 0.040 | 0.040 | 235 | 370 | |

| D | 0.17 | 1.4 | 0.35 | 0.035 | 0.035 | 235 | 370 | |

| GB/T1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

| B | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| C | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| I-BS EN10025 | S235JR | 0.17 | 1.4 | - | 0.035 | 0.035 | 235 | 360 |

| S275JR | 0.21 | 1.5 | - | 0.035 | 0.035 | 275 | 410 | |

| S355JR | 0.24 | 1.6 | - | 0.035 | 0.035 | 355 | 470 | |

| I-DIN 17100 | ST37-2 | 0.2 | - | - | 0.050 | 0.050 | 225 | 340 |

| ST44-2 | 0.21 | - | - | 0.050 | 0.050 | 265 | 410 | |

| ST52-3 | 0.2 | 1.6 | 0.55 | 0.040 | 0.040 | 345 | 490 | |

| I-JIS G3101 | SS400 | - | - | - | 0.050 | 0.050 | 235 | 400 |

| SS490 | - | - | - | 0.050 | 0.050 | 275 | 490 | |

| I-API 5L PSL1 | A | 0.22 | 0.9 | - | 0.03 | 0.03 | 210 | 335 |

| B | 0.26 | 1.2 | - | 0.03 | 0.03 | 245 | 415 | |

| X42 | 0.26 | 1.3 | - | 0.03 | 0.03 | 290 | 415 | |

| I-X46 | 0.26 | 1.4 | - | 0.03 | 0.03 | 320 | 435 | |

| X52 | 0.26 | 1.4 | - | 0.03 | 0.03 | 360 | 460 | |

| I-X56 | 0.26 | 1.1 | - | 0.03 | 0.03 | 390 | 490 | |

| I-X60 | 0.26 | 1.4 | - | 0.03 | 0.03 | 415 | 520 | |

| I-X65 | 0.26 | 1.45 | - | 0.03 | 0.03 | 450 | 535 | |

| X70 | 0.26 | 1.65 | - | 0.03 | 0.03 | 585 | 570 | |

Okujwayelekile kanye neBanga

| Okujwayelekile | Amabanga Ensimbi |

| I-API 5L: Imininingwane yepayipi yomugqa | GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| I-ASTM A252: Imininingwane Ejwayelekile Yamapayipi Ensimbi Ahlanganisiwe Nangenamthungo | GR.1, GR.2, GR.3 |

| I-EN 10219-1: Izingxenye Ezingenalutho Ezihlanganisiwe Ezibunjiwe Zesakhiwo Esingena-alloy Nezinhlayiya Ezinhle | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-EN10210: Izingxenye Ezingenalutho Eziqediwe Zesakhiwo Ezingena-Alloy Nezinhlayiya Ezinhle | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-ASTM A53/A53M: Ipayipi, Insimbi, Emnyama futhi Ecwiliswe Ngokushisayo, Embozwe Ngezinki, Ehlanganisiwe Futhi Engenamthungo | GR.A, GR.B |

| I-EN10208: Amapayipi ensimbi asetshenziswa ezinhlelweni zokuthutha amapayipi embonini kaphethiloli negesi yemvelo. | L210GA, L235GA, L245GA, L290GA, L360GA |

| EN 10217: Amapayipi Ensimbi Ahlanganisiwe Ngezinhloso Zokucindezela | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| I-DIN 2458: Amapayipi Nezipayipi Zensimbi Ezihlanganisiwe | St37.0, St44.0, St52.0 |

| I-AS/NZS 1163: Izinga lase-Australia/laseNew Zealand lezingxenye zensimbi ezakhiwe ngendlela ebandayo | Ibanga C250 , Ibanga C350 , Ibanga C450 |

| GB/T 9711: Izimboni Zikaphethiloli Negesi Yemvelo - Ipayipi Lensimbi Lamapayipi | L175, L210, L245, L290, L320 , L360, L390 , L415, L450 , L485 |

| I-ASTM A671: Ipayipi Lensimbi Elihlanganisiwe Likagesi Lokuhlanganiswa Komoya Namazinga Okushisa Aphansi | I-CA 55, CB 60, CB 65, CB 70, CC 60, CC 65, CC 70 |

| I-ASTM A672: Ipayipi lensimbi elihlanganisiwe ngogesi ukuze lisebenze ngomfutho ophezulu emazingeni okushisa aphakathi nendawo. | A45, A50, A55, B60, B65, B70, C55, C60, C65 |

| I-ASTM A691: Ipayipi lensimbi yekhabhoni ne-alloy, elihlanganiswe ngogesi ukuze lisebenze ngokucindezela okuphezulu emazingeni okushisa aphezulu. | CM-65, CM-70, CM-75, 1/2CR-1/2MO, 1CR-1/2MO, 2-1/4CR, 3CR |

Inqubo Yokukhiqiza

Ikhwalithi yokulawula

● Ukuhlola Izinto Ezingavuthiwe

● Ukuhlaziywa Kwamakhemikhali

● Ukuhlolwa Kwemishini

● Ukuhlolwa Okubonakalayo

● Ukuhlola Ubukhulu

● Ukuhlolwa Kokugoba

● Ukuhlolwa Komthelela

● Ukuhlolwa Kokugqwala Okuphakathi Kwezinhlayiya

● Ukuhlolwa Okungabhubhisi (UT, MT, PT)

● Iziqu Zenqubo Yokushisela

● Ukuhlaziywa kwesakhiwo esincane

● Ukuhlolwa Kokuvutha Nokuthamba

● Ukuhlolwa Kokuqina

● Ukuhlolwa Kwamanzi

● Ukuhlolwa kwe-Metallography

● Ukuhlolwa Kokuqhekeka Okubangelwa Yi-Hydrogen (HIC)

● Ukuhlolwa Kokuqhekeka Kokucindezeleka Kwe-Sulfide (SSC)

● Ukuhlolwa Kwamanje kwe-Eddy

● Ukuhlolwa Kokupenda Nokumboza

● Ukubuyekezwa Kwamadokhumenti

Ukusetshenziswa Nokusetshenziswa

Amapayipi ensimbi e-LSAW (Longitudinal Submerged Arc Welding) athola izinhlelo zokusebenza ezahlukahlukene emikhakheni eyahlukene ngenxa yobuqotho bawo besakhiwo kanye nokuguquguquka kwawo. Ngezansi ezinye zezindlela ezibalulekile zokusebenzisa kanye nokusetshenziswa kwamapayipi ensimbi e-LSAW:

● Ukuthuthwa Kwamafutha Negesi: Amapayipi ensimbi e-LSAW asetshenziswa kakhulu embonini kawoyela negesi ezinhlelweni zamapayipi. Lawa mapayipi asetshenziselwa ukuthutha uwoyela ongahluziwe, igesi yemvelo, kanye nolunye uketshezi noma amagesi.

● Ingqalasizinda Yamanzi: Amapayipi e-LSAW asetshenziswa kumaphrojekthi engqalasizinda ahlobene namanzi, okuhlanganisa ukuhlinzekwa kwamanzi kanye nezinhlelo zokukhipha amanzi.

● Ukucubungula Amakhemikhali: Amapayipi e-LSAW asebenza ezimbonini zamakhemikhali lapho asetshenziswa khona ukuthutha amakhemikhali, uketshezi, namagesi ngendlela ephephile nephumelelayo.

● Ukwakhiwa kanye Nengqalasizinda: Lawa mapayipi asetshenziswa kumaphrojekthi ahlukahlukene okwakha, njengezisekelo zokwakha, amabhuloho, kanye nezinye izinhlelo zokusebenza zesakhiwo.

● Ukufaka inqwaba: Amapayipi e-LSAW asetshenziswa ekufakweni kwenqwaba ukuze anikeze ukwesekwa kwesisekelo kumaphrojekthi okwakha, okuhlanganisa izisekelo zokwakha kanye nezakhiwo zasolwandle.

● Umkhakha Wamandla: Zisetshenziselwa ukuthutha izinhlobo ezahlukene zamandla, okuhlanganisa umusi kanye noketshezi olushisayo ezitshalweni zokukhiqiza ugesi.

● Ukumba: Amapayipi e-LSAW asetshenziswa kumaphrojekthi okumba ukuthutha izinto kanye nezinsila.

● Izinqubo Zezimboni: Izimboni ezifana nokukhiqiza nokukhiqiza zisebenzisa amapayipi e-LSAW ezinqubweni ezahlukene zezimboni, okuhlanganisa ukuthutha izinto zokusetshenziswa kanye nemikhiqizo eqediwe.

● Ukuthuthukiswa Kwengqalasizinda: Lawa mapayipi abalulekile ekuthuthukiseni amaphrojekthi engqalasizinda njengemigwaqo, imigwaqo emikhulu, kanye nezinsizakusebenza ezingaphansi komhlaba.

● Ukusekelwa Kwesakhiwo: Amapayipi e-LSAW asetshenziselwa ukwakha izisekelo zesakhiwo, izinsika, kanye nemishayo kumaphrojekthi okwakha nobunjiniyela.

● Ukwakha imikhumbi: Embonini yokwakha imikhumbi, amapayipi e-LSAW asetshenziswa ekwakheni izingxenye ezahlukene zemikhumbi, okuhlanganisa amagobolondo kanye nezingxenye zesakhiwo.

● Imboni Yezimoto: Amapayipi e-LSAW angasetshenziswa ekukhiqizweni kwezingxenye zezimoto, okuhlanganisa nezinhlelo zokukhipha ugesi.

Lezi zinhlelo zokusebenza zibonisa ukuguquguquka kwamapayipi ensimbi e-LSAW emikhakheni ehlukene, ngenxa yokuqina kwawo, amandla, kanye nokufaneleka kwawo ezimweni ezahlukene zemvelo.

Ukupakisha Nokuthumela

Ukupakishwa kahle kanye nokuthunyelwa kwamapayipi ensimbi e-LSAW (Longitudinal Submerged Arc Welding) kubalulekile ukuqinisekisa ukuthuthwa kwawo okuphephile kanye nokulethwa ezindaweni ezahlukene. Nansi incazelo yezinqubo ezijwayelekile zokupakisha kanye nokuthunyelwa kwamapayipi ensimbi e-LSAW:

Ukupakisha:

● Ukubopha: Amapayipi e-LSAW avame ukuhlanganiswa ndawonye noma apakishwe nge-Single Piece kusetshenziswa izintambo zensimbi noma amabhande ukuze kudalwe amayunithi aphathekayo okuphatha nokuthuthwa.

● Isivikelo: Iziphetho zamapayipi zivikelwe ngezivalo zepulasitiki ukuvimbela umonakalo ngesikhathi sokuhamba. Ngaphezu kwalokho, amapayipi angambozwa ngezinto zokuvikela ukuze kuvikelwe ezicini zemvelo.

● Ukuvikela Ukugqwala: Uma amapayipi ene-anti-corrosion coating, ubuqotho be-coating buyaqinisekiswa ngesikhathi sokupakisha ukuze kuvinjelwe umonakalo ngesikhathi sokuphatha nokuthuthwa.

● Ukumaka Nokulebula: Iphakheji ngayinye ilebula ngolwazi olubalulekile njengosayizi wepayipi, ibanga lezinto, inombolo yokushisa, kanye nezinye izici ukuze kube lula ukuyibona.

● Ukubopha: Amabhandishi aboshelwa ngokuqinile kuma-pallet noma kuma-skid ukuvimbela ukunyakaza ngesikhathi sokuthuthwa.

Ukuthunyelwa:

● Izindlela Zokuhamba: Amapayipi ensimbi e-LSAW angathunyelwa kusetshenziswa izindlela ezahlukene zokuhamba, okuhlanganisa umgwaqo, isitimela, ulwandle, noma umoya, kuye ngokuthi uya kuphi kanye nokuphuthuma.

● Ukufakwa kweziqukathi: Amapayipi angathunyelwa ngeziqukathi ukuze kuvikelwe kakhulu, ikakhulukazi ngesikhathi sokuthuthwa kwamanye amazwe. Iziqukathi ziyalayishwa futhi ziboshwe ukuze kuvinjelwe ukugudluka ngesikhathi sokuthuthwa.

● Ozakwethu Bezokuthutha: Izinkampani zokuthutha noma abathwali abadumile abanokuhlangenwe nakho kokuphatha amapayipi ensimbi bayaqashwa ukuqinisekisa ukulethwa okuphephile nangesikhathi.

● Imibhalo Yentela Yempahla: Imibhalo yentela yempahla edingekayo, okuhlanganisa izincwadi zokuthutha impahla, izitifiketi zomsuka, kanye neminye imibhalo efanele, iyalungiswa futhi ithunyelwe ukuze ithunyelwe kwamanye amazwe.

● Umshwalense: Kuye ngenani kanye nohlobo lwempahla, umshwalense ungahlelwa ukuze uvikeleke ezigamekweni ezingalindelekile ngesikhathi sokuthutha.

● Ukulandelela: Izinhlelo zokulandelela zesimanje zivumela umthumeli kanye nomamukeli ukulandelela inqubekela phambili yokuthunyelwa ngesikhathi sangempela, okuqinisekisa ukucaca kanye nokubuyekezwa okufika ngesikhathi.

● Ukulethwa: Amapayipi akhishwa endaweni oya kuyo, kulandelwa izinqubo ezifanele zokukhipha ukuze kugwenywe umonakalo.

● Ukuhlolwa: Lapho efika, amapayipi angahlolwa ukuqinisekisa isimo sawo kanye nokuhambisana nezimiso ngaphambi kokuba amukelwe ngumamukeli.

Imikhuba efanele yokupakisha nokuthumela impahla isiza ekuvimbeleni umonakalo, igcine ubuqotho bamapayipi ensimbi e-LSAW, futhi iqinisekise ukuthi afika ezindaweni zawo ezihlosiwe ngokuphephile futhi esesimweni esihle.