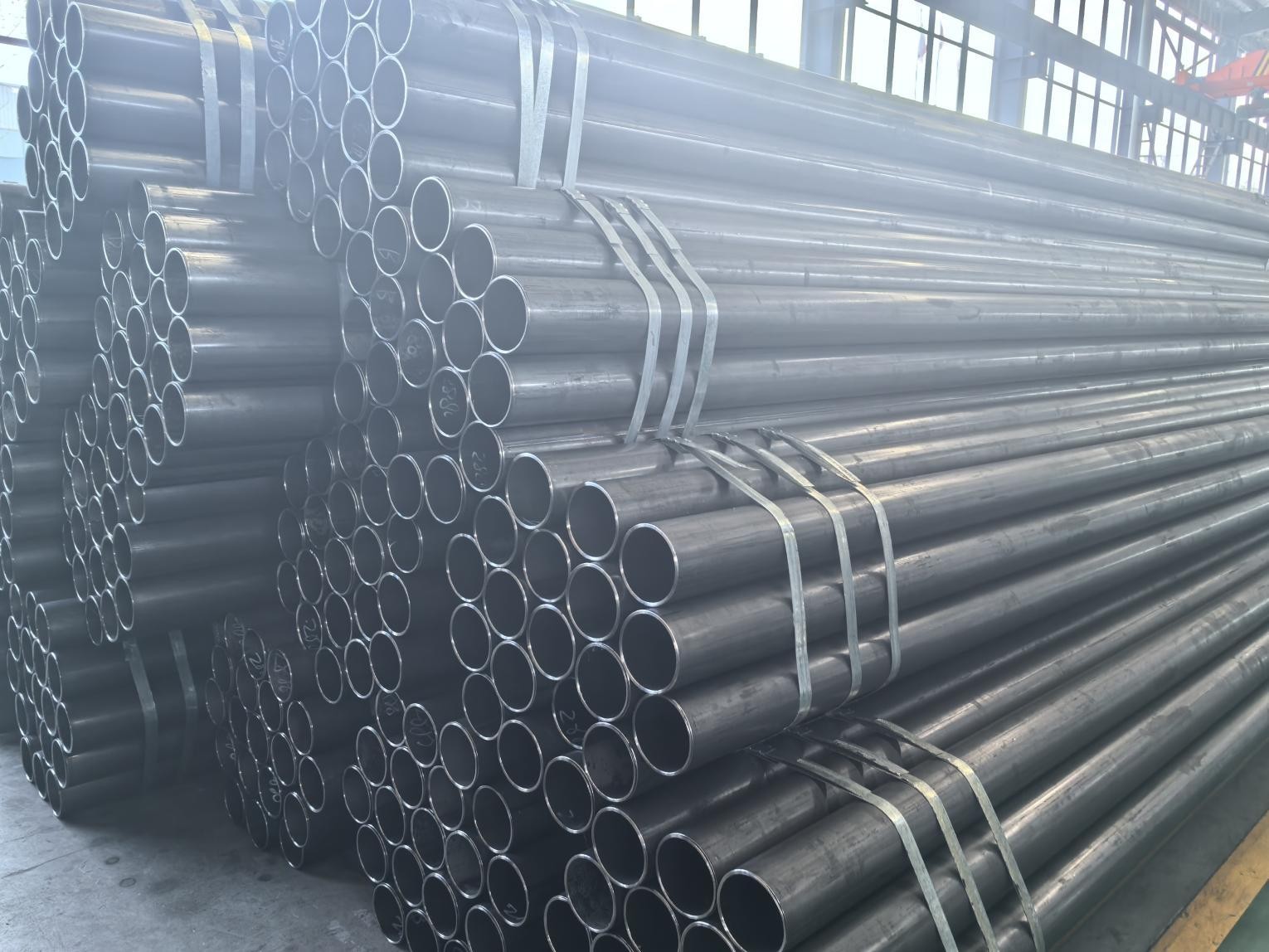

I-Womic Steel igxile ekukhiqizweni kwamapayipi ensimbi asezingeni eliphezulu ahambisana nemithethoI-DIN 2391amazinga. Amapayipi ethu aklanyelwe izinhlelo eziningi ezahlukene, okuhlanganisa nezinhlelo zokuthutha zesakhiwo, zemishini, kanye nezoketshezi. Sisebenzisa ubuchwepheshe bokukhiqiza obuthuthukisiwe kanye nezinqubo zokulawula ikhwalithi eziqinile, siqinisekisa ukuthi imikhiqizo yethu ihlangabezana nezindinganiso zomhlaba wonke, ihlinzeka ngokuqina okungenakuqhathaniswa, ukunemba, kanye nokusebenza.

Amapayipi ethu ensimbi afaneleka kakhulu ukusetshenziswa kuma-idlers, amasilinda e-hydraulic kanye ne-pneumatic, ubunjiniyela bemishini kanye nezimoto, imishini, amashubhu esilinda kawoyela, amashubhu ensimbi e-shock absorber yesithuthuthu, kanye namasilinda angaphakathi e-auto shock absorber. Lezi zinhlelo zokusebenza zidinga amapayipi anamandla aphezulu, aklanywe ngokunemba anikeza ukuthembeka nokusebenza okuhle kakhulu ezindaweni ezidinga amandla amaningi.

I-DIN 2391 Amashubhu Okucacisa Okungenamthungo Uhla Lokukhiqiza:

- Ububanzi Bangaphandle (OD): 6 mm kuya ku-400 mm

- Ubukhulu Bodonga (WT): 1 mm kuya ku-18 mm

- Ubude: Ubude obungokwezifiso buyatholakala, ngokuvamile busukela kumamitha ayi-6 kuya kwayi-12, kuye ngezidingo zephrojekthi.

I-DIN 2391 Amashubhu Okucacisa Okungenamthungo Ukubekezelelana:

| Ipharamitha | Ukubekezelelana |

| Ububanzi Bangaphandle (OD) | ± 0.01mm |

| Ubukhulu Bodonga (WT) | ± 0.1 mm wobukhulu bodonga obuchaziwe |

| Ukuma (Ukuma) | 0.1 mm |

| Ubude | ± 5 mm |

| Ukuqonda | Ubuningi obungu-1 mm ngemitha |

| Ukuqedwa Komphezulu | Ngokwencazelo yekhasimende (Ngokuvamile: Uwoyela Olwa Nokugqwala, Ukufakwa kwe-chrome eqinile, Ukufakwa kwe-chromium ye-nickel, noma okunye Ukufakwa) |

| Ubungako Beziphetho | ± 1° |

I-DIN 2391 Amashubhu Okucacisa Okungenamthungo Ukwakheka Kwamakhemikhali

| Okujwayelekile | Ibanga | Izingxenye Zamakhemikhali (%) | |||||

| Uphawu | Inombolo Yezinto Ezisetshenziswayo | C | Si | Mn | P | S | |

| I-DIN2391 | St 30 Si | 1.0211 | ≤0.10 | ≤0.30 | ≤0.55 | ≤0.025 | ≤0.025 |

| St 30 Al | 1.0212 | ≤0.10 | ≤0.05 | ≤0.55 | ≤0.025 | ≤0.025 | |

| ISt 35 | 1.0308 | ≤0.17 | ≤0.35 | ≥0.40 | ≤0.025 | ≤0.025 | |

| ISt 5 | 1.0408 | ≤0.21 | ≤0.35 | ≥0.40 | ≤0.025 | ≤0.025 | |

| ISt 52 | 1.058 | ≤0.22 | ≤0.55 | ≤1.60 | ≤0.025 | ≤0.025 | |

Izinto ezilandelayo zokuhlanganisa zingangezwa: Nb: ≤ 0,03 %; Ti: ≤ 0,03 %; V: ≤ 0,05 %; Nb + Ti + V: ≤ 0,05 %

I-DIN 2391 Amashubhu Okucacisa Okungenamthungo Izimo Zokulethwa

Amapayipi kumele akhiqizwe ngezinqubo ezidonswayo noma ezigoqwe ngokubandayo. Amapayipi kumele ahlinzekwe ngaphansi kwesinye sezimo zokulethwa kanje:

| Ukuqokwa | Uphawu | Incazelo |

| Kuqediwe kubanda (kunzima) | BK | Amapayipi awaphathwa ngokushisa ngemva kokwakheka kokugcina kokubanda futhi ngenxa yalokho, amelana kakhulu nokuguquguquka. |

| Kuqediwe kubanda (kuthambile) | I-BKW | Ukwelashwa kokugcina kokushisa kulandelwa ukudweba okubandayo okubandakanya ukuguquguquka okulinganiselwe. Ukucubungula okuqhubekayo okufanele kuvumela izinga elithile lokwakheka kokubanda (isb. ukugoba, ukunwebeka). |

| Kuqediwe ukubanda futhi kuncishiswe ukucindezeleka | I-BKS | Ukwelashwa ngokushisa kusetshenziswa ngemva kwenqubo yokugcina yokwakheka kobandayo. Kuye ngezimo zokucubungula ezifanele, ukwanda kokucindezeleka okusele okuhilelekile kwenza kokubili ukwakheka kanye nokucubungula ngezinga elithile. |

| I-Annealed | I-GBK | Inqubo yokugcina yokwakheka komkhuhlane ilandelwa ukucwiliswa emoyeni olawulwayo. |

| Okujwayelekile | I-NBK | Inqubo yokugcina yokwakheka komkhuhlane ilandelwa ukuncibilikisa ngaphezu kwendawo yokuguqula ephezulu emoyeni olawulwayo. |

I-DIN 2391 Amashubhu Okucacisa Okungenamthungo Izakhiwo Zemishini.

| Izakhiwo zemishini ekushiseni kwegumbi | |||||||||||||

| Ibanga Lensimbi | Amanani aphansi kakhulu esimo sokulethwa | ||||||||||||

| Igama Lensimbi | Inombolo Yensimbi | BK | I-BKW | I-BKS | I-GBK | I-NBK | |||||||

| Rm | I-% | Rm | I-% | Rm | I-ReH | I-% | Rm | I-% | Rm | I-ReH | I-% | ||

| I-Mpa | I-Mpa | I-Mpa | I-Mpa | I-Mpa | I-Mpa | I-Mpa | |||||||

| St 30 Si | 1.0211 | 430 | 8 | 380 | 12 | 380 | 280 | 16 | 280 | 30 | 290 kuya ku-420 | 215 | 30 |

| St 30 Al | 1.0212 | 430 | 8 | 380 | 12 | 380 | 280 | 16 | 280 | 30 | 290 kuya ku-420 | 215 | 30 |

| ISt 35 | 1.0308 | 480 | 6 | 420 | 10 | 420 | 315 | 14 | 315 | 25 | 340 kuya ku-470 | 235 | 25 |

| ISt 45 | 1.0408 | 580 | 5 | 520 | 8 | 520 | 375 | 12 | 390 | 21 | 440 kuya ku-570 | 255 | 21 |

| ISt 52 | 1.0580 | 640 | 4 | 580 | 7 | 580 | 420 | 10 | 490 | 22 | 490 kuya ku-630 | 355 | 22 |

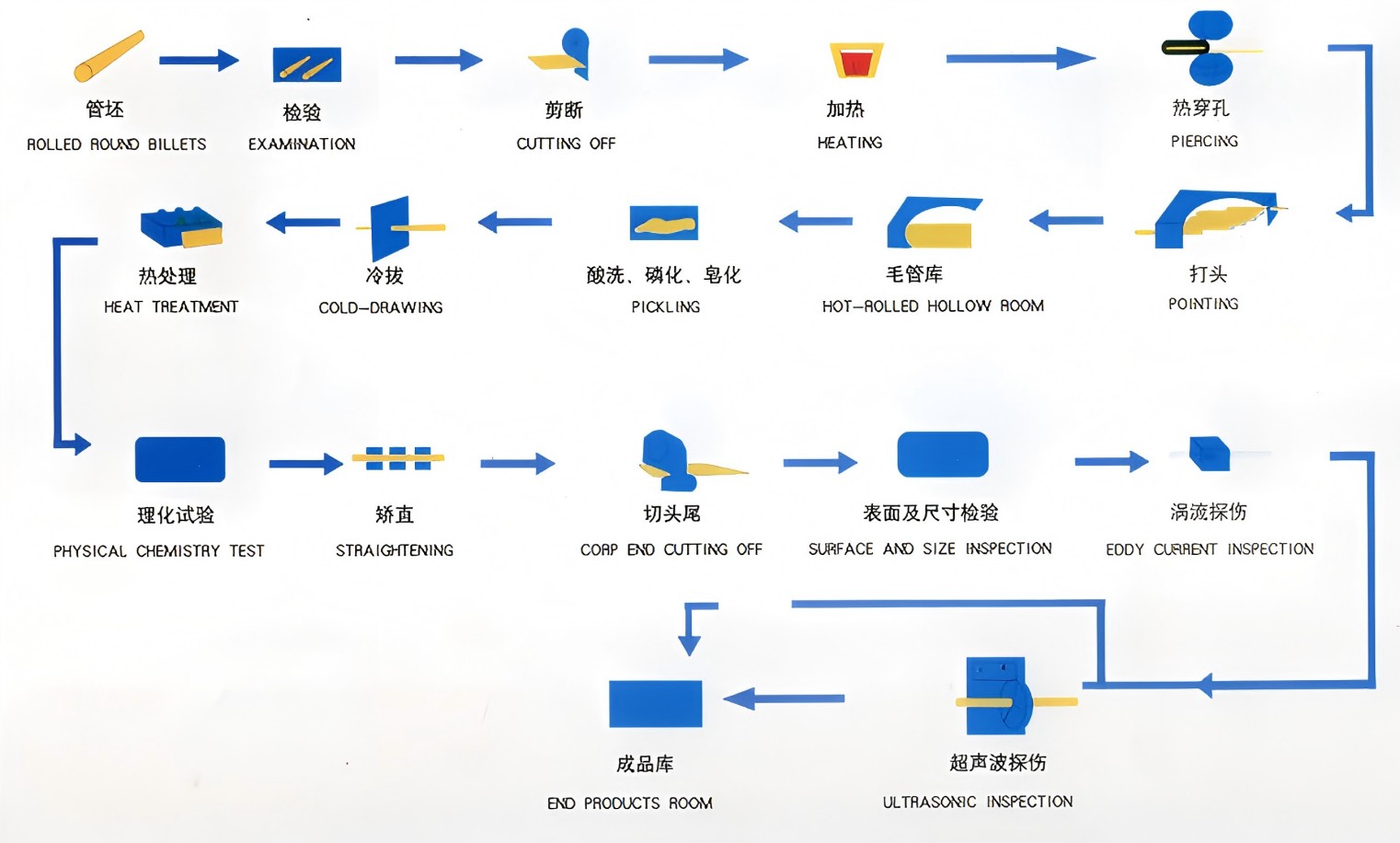

I-DIN 2391 Amashubhu Okucacisa Okungenamthungo Inqubo Yokukhiqiza:

- ·Ama-Billets Ayindilinga Agoqiwe: Ukukhiqizwa kuqala ngokusetshenziswa kwama-billets ayindilinga asongiwe, okuyizinto zokuqala zokusetshenziswa ngendlela yezinduku zensimbi.

- ·Ukuhlolwa: Lawa ma-billet ahlolwa kuqala ukuze atholakale ukuthi asezingeni elifanele kanye nokuvumelana ukuze kuqinisekiswe ukuthi ayahlangabezana nezindinganiso ezidingekayo ngaphambi kokuqhubekela esinyathelweni esilandelayo.

- ·Ukusika: Ama-billet abe esenqunywa abe ubude obufunekayo ukuze avumelane nezidingo zokucutshungulwa okuqhubekayo.

- ·Ukushisa: Ama-billet anqunyiwe ashiswa ekushiseni okuphezulu ukuze afanelekele ukuguguleka okuqhubekayo ezinyathelweni ezilandelayo.

- ·Ukubhoboza: Ama-billet afudumele abe esebhobozwa ukuze kudalwe isikhungo esingenalutho, esakha isakhiwo esiyisisekelo sepayipi elingenamthungo.

- ·Igumbi Elingenalutho Eligoqekile Elishisayo: Ama-billet angenalutho aqhutshwa ngokushisa ukuze akhe ipayipi.

- ·Kudonswe Ngokubandayo: Amapayipi aguqiwe ashisayo abe esedonswa ngedayi ngaphansi kwezimo ezilawulwayo, kunciphisa ububanzi nobukhulu, bese kuhlungwa ubukhulu bepayipi.

- ·Ukukhahlela: Amapayipi afakwa ku-asidi ukuze kususwe noma yikuphi ukukala kobuso noma ukungcola okwakhiwe ngesikhathi senqubo yokukhiqiza.

- ·Ukwelashwa Kokushisa: Amapayipi aphathwa ngokushisa, okubandakanya izinqubo ezifana nokunamathisela ukuze kuthuthukiswe izakhiwo zawo zemishini futhi kuncishiswe ukucindezeleka.

- ·Ukuhlolwa Kwekhemikhali Yomzimba: Amapayipi ahlolwa ngokomzimba nangokwekhemikhali ukuqinisekisa ukuthi ayahlangabezana nezimfuneko zezinto zokwakha kanye nezakhiwo.

- ·Ukuqondisa: Ngemva kokwelashwa ngokushisa, amapayipi ayaqondiswa ukuqinisekisa ukufana kwawo nokunemba kwawo.

- ·Ukusika Ukuphela Kwekhoyili: Iziphetho zamapayipi zinqunyiwe zibe ubude obudingekayo.

- ·Ukuhlolwa Komphezulu Nobukhulu: Amapayipi ahlolwa kahle ukuze kutholakale amaphutha ebusweni futhi ahlolwe ukuthi anembile yini ukuze kuqinisekiswe ikhwalithi.

- ·Ukuhlolwa Kwamanje kwe-Eddy: Lokhu kuhlola okungonakalisi kusetshenziselwa ukuthola noma yikuphi ukuqhekeka noma amaphutha angase angabonakali ngeso lenyama.

- ·Ukuhlolwa kwe-Ultrasonic: Amapayipi ahlolwa nge-ultrasound ukuthola noma yiziphi iziphambeko zangaphakathi noma amaphutha angathinta amandla noma ubuqotho bepayipi.

- ·Igumbi Lemikhiqizo YokugcinaEkugcineni, amapayipi aqediwe athunyelwa egumbini lemikhiqizo yokugcina, lapho apakishwa khona futhi alungiselelwe ukuthunyelwa.

Ukuhlola Nokuhlola:

I-Womic Steel iqinisekisa ukulandeleka okugcwele kanye nokuqinisekiswa kwekhwalithi yama-allDIN 2391 Seamless Precision Tubes ngokusebenzisa izivivinyo ezilandelayo:

- Ukuhlolwa Kobukhulu: Ukulinganiswa kwe-OD, i-WT, ubude, ukujiya, kanye nokuqondile.

- Ukuhlolwa Kwemishini:

- Ukuhlolwa Kokunamathela

- Ukuhlolwa Komthelela

- Ukuhlolwa Kokuqina

- Ukuhlolwa Okungonakalisi (NDT):Ukuhlaziywa Kwamakhemikhali: Kwenziwa ukuqinisekisa ukwakheka kwezinto kusetshenziswa izindlela ze-spectrographic.

- Ukuhlolwa Kwamanje kwe-Eddy kwamaphutha angaphakathi

- Ukuhlolwa kwe-Ultrasonic (UT) kobukhulu bodonga kanye nobuqotho

- Ukuhlolwa Kwamanzi: Ukuhlola ikhono lepayipi lokubekezelela ingcindezi yangaphakathi ngaphandle kokwehluleka.

Ukulawulwa Kwelebhu Nokwekhwalithi:

I-Womic Steel isebenzisa ilabhorethri ehlonyiswe ngokugcwele enemishini yokuhlola nokuhlola ethuthukisiwe ukuqinisekisa ukuhambisana nezindinganiso ze-DIN 2391 Seamless Precision Tubes. Ochwepheshe bethu bezobuchwepheshe benza ukuhlolwa kwekhwalithi njalo ngaphakathi kwendlu kuwo wonke amapayipi. Sisebenzisana eduze nezinhlangano ezizimele zezinkampani zangaphandle ukuze kuqinisekiswe ikhwalithi yamapayipi ngaphandle.

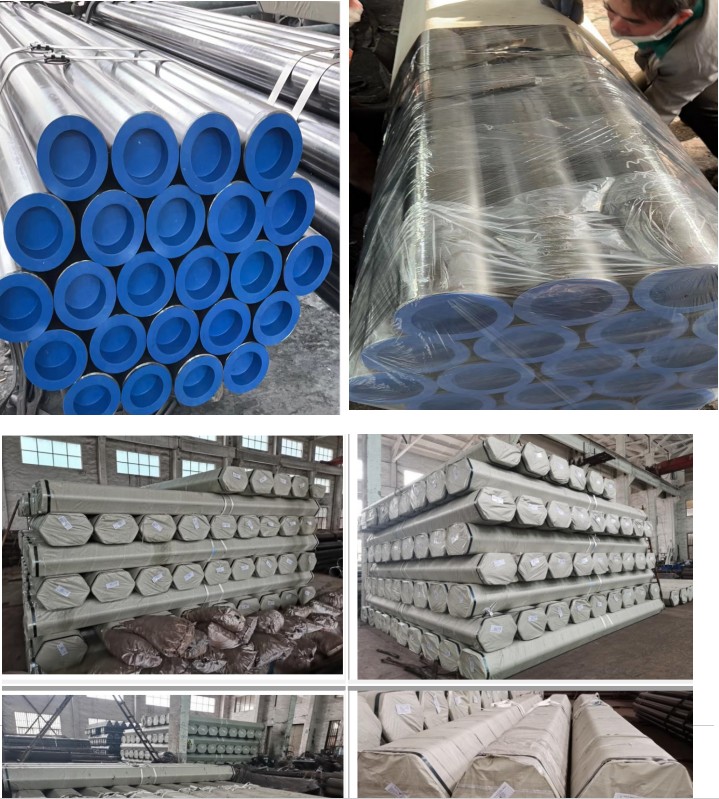

Ukupakisha

Isimbozo Esivikelayo: Ithubhu ngalinye liyahlanzwa futhi limbozwe ngesendlalelo sokulwa nokugqwala ukuvimbela ukugqwala noma ukugqwala ngesikhathi sokuthuthwa nokugcinwa. Lokhu kungafaka ungqimba lwamafutha, i-wax, noma ezinye izembozo zokuvikela ngokwezidingo zamakhasimende.

Ama-End Caps: Zombili iziphetho zamapayipi zivalwe ngezivalo zepulasitiki noma zensimbi ukuvimbela ukungcola, umswakama, kanye nomonakalo ngesikhathi sokuphathwa nokuthuthwa.

Ukuhlanganisa: Amashubhu ahlanganiswa abe amaphakheji aphathekayo, ngokuvamile ngobude obuhambisana nezidingo zokuthumela ezijwayelekile. Amashubhu asongwa ngezintambo zensimbi, amabhande epulasitiki, noma amabhande alukiwe ukuze abambeke ndawonye ngokuphephile.

Ukuvikelwa phakathi kwamapayipi: Ukuze kugwenywe ukuthintana ngqo nokuvimbela ukuklwebheka noma umonakalo, amashubhu angaphakathi kwezinqwaba avame ukuhlukaniswa ngezinto zokuzivikela ezifana nekhadibhodi, izihlukanisi zokhuni, noma izinto zokufaka igwebu.

Izinto Zokupakisha: Izinqwaba zamashubhu zivame ukugoqwa nge-shrink wrap noma ifilimu yepulasitiki eqinile ukuqinisekisa ukuthi zihlala ziphelele ngesikhathi sokuthuthwa futhi zivikelwe othulini nasemswakama.

Ukuhlonza Nokulebula: Iphakheji ngayinye imakwe ngokucacile ngemininingwane yomkhiqizo, okuhlanganisa ibanga lensimbi, ubukhulu (ububanzi, ukujiya, ubude), ubuningi, inombolo yebhetshi, kanye nezinye izici ezifanele. Amalebula angafaka imiyalelo yokuphatha efana nokuthi "Gcina Komile" noma "Phatha Ngokucophelela."

Ezokuthutha

Indlela Yokuthutha:

Impahla Yasolwandle: Uma kuthunyelwa kwamanye amazwe, amashubhu anembile angenamthungo avame ukuthunyelwa ngolwandle. Amashubhu alayishwa ezitsheni zokuthumela noma kuma-rack ayisicaba, kuye ngobukhulu nobude bamashubhu.

Isitimela noma Ezokuthutha Emgwaqweni: Uma kuthunyelwa izinto zasekhaya noma zesifunda, amapayipi angathuthwa ngesitimela noma ngomgwaqo, alayishwe emalolini ayisicaba noma ezitsheni.

Ukulayisha Nokuvikela: Uma zilayishwa ezimotweni zokuthutha, izinqwaba ziboshelwa ngokuqinile ukuze kuvinjelwe ukugudluka noma ukunyakaza ngesikhathi sokuhamba. Lokhu kungafezwa kusetshenziswa izintambo zensimbi, amabhande epulasitiki, kanye nokubopha okwengeziwe ngaphakathi kwesitsha noma iloli. Uma kuthuthwa ngolwandle, uma amapayipi engekho ezitsheni, avame ukulayishwa ezingodweni ezisicaba futhi aboshwe ngama-tarps noma izembozo ezengeziwe ukuze azivikele ezimweni zezulu ezifana nokuchayeka emvuleni noma emanzini anosawoti.

Ukulawulwa Kwesimo SezuluUma kudingeka (ikakhulukazi ezindaweni ezinomswakama noma ezisogwini), izimo zokuhamba ezilawulwayo (isb., ukulawulwa kwezinga lokushisa kanye nomswakama) zingahlelwa ukuze kuvinjelwe noma yimuphi umonakalo ovela ezintweni zemvelo ngesikhathi sokuthutha.

Imibhalo: Amadokhumenti okuthumela afanele alungiselelwe ukusulwa kwempahla kanye nokulandelwa kwezokuthutha, okuhlanganisa i-bill of lading, isitifiketi semvelaphi, izitifiketi zekhwalithi, kanye neminye imibhalo edingekayo yokulawula.

Umshwalense: Ukuze kuvikelwe ekulimaleni, ekulahlekeni, noma ekwebiweni okungenzeka ngesikhathi sokuthutha, kunconywa ukuhlela umshwalense wokuthunyelwa, ikakhulukazi kokuthunyelwa kwamanye amazwe.

Izinzuzo Zokukhetha Insimbi Yabesifazane:

- Ukukhiqiza Ngokucophelela: Izinqubo zethu zokukhiqiza zesimanje zisivumela ukuthi sihlangabezane nokubekezelelana okuqinile kobubanzi, ukujiya kodonga, kanye nokuma kwe-oval.

- Izinto Ezisezingeni Eliphezulu: Sithola kuphela insimbi yezinga eliphezulu kakhulu kubaphakeli abathembekile, siqinisekisa izakhiwo ezinhle kakhulu zemishini kanye nokumelana nokugqwala.

- Ukwenza ngokwezifiso: Sinikeza izixazululo ezenzelwe wena ngokusekelwe ezidingweni zamakhasimende, kufaka phakathi ubude obuthile, ukwelashwa kwendawo, kanye nezinketho zokupakisha.

- Ukuhlolwa Okuphelele: Ngezinqubo zethu zokuhlola eziqinile, siqinisekisa ukuthi ipayipi ngalinye lihlangabezana nazo zonke izidingo zobuchwepheshe nezokulawula, linikeza ukusebenza okuthembekile nokuhlala isikhathi eside.

- Ithimba Elinolwazi: Ithimba lethu lonjiniyela kanye nochwepheshe banekhono eliphezulu nolwazi, baqinisekisa amazinga aphezulu ekukhiqizeni kanye nensizakalo yamakhasimende.

- Ukulethwa Ngesikhathi: Sisebenza nenethiwekhi ye-logistics ethembekile, siqinisekisa ukulethwa ngesikhathi kunoma iyiphi ingxenye yomhlaba.

Isiphetho:

Amashubhu e-Womic Steel e-DIN 2391 Seamless Precision ahambisana nokusebenza okuphezulu, ukuqina, kanye nokukhiqizwa okunembile. Ukuzibophezela kwethu ekhwalithini kanye nokwaneliseka kwamakhasimende kusenza sahluke njengabaholi ekukhiqizweni kwamapayipi ensimbi. Kungakhathaliseki ukuthi kungokwakha, imishini, noma izinhlelo zoketshezi, imikhiqizo yethu yenzelwe ukuhlangabezana nezindinganiso eziphakeme kakhulu zokuthembeka namandla.

Khetha i-Womic Steel Group njengomlingani wakho othembekile wamapayipi nezinsimbi zensimbi engagqwali ezisezingeni eliphezulu kanye nokusebenza kahle kokulethwa. Siyakwamukela Umbuzo!

Iwebhusayithi: www.womicsteel.com

I-imeyili: sales@womicsteel.com

Ucingo/I-WhatsApp/I-WeChat: Victor: +86-15575100681 noma uJack: +86-18390957568