Incazelo Yomkhiqizo

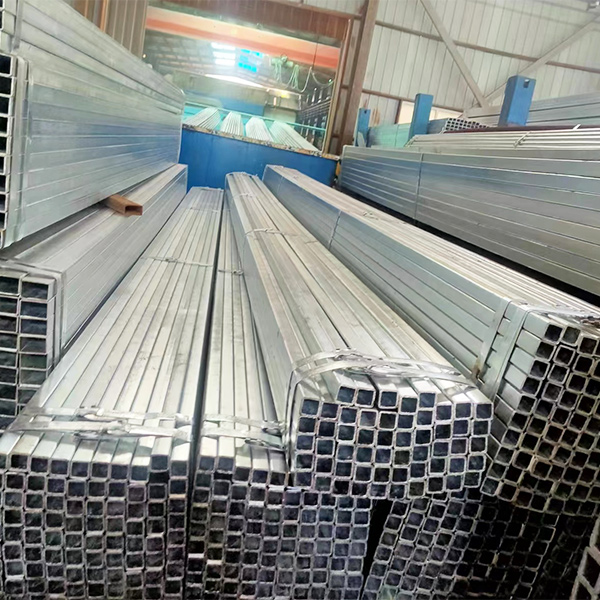

Amapayipi ensimbi ahlanganisiwe angamapayipi ensimbi akhiqizwa nge-zinc coating evikelwe ukuze kuvinjelwe ukugqwala nokugqwala. Ipayipi lensimbi elihlanganisiwe lingahlukaniswa libe yipayipi elishisayo elihlanganisiwe kanye nepayipi elingaphambi kokuhlanganiswa. Ingqimba ye-hot-dip galvanizing ijiyile, ine-plating efanayo, ukunamathela okuqinile kanye nokuphila isikhathi eside.

Amapayipi okufaka isikhafu sensimbi nawo uhlobo lwamapayipi ahlanganisiwe ayi-scaffolding yomsebenzi wangaphakathi nowangaphandle, enziwe ngensimbi yeshubhu. Amapayipi okufaka isikhafu alula, anikeza ukumelana nomoya okuphansi, futhi amapayipi okufaka isikhafu ahlanganiswa futhi ahlakazwe kalula. Amapayipi okufaka isikhafu se-galvanized atholakala ngobude obuhlukahlukene ukuze kube nokuphakama okuhlukahlukene kanye nezinhlobo zomsebenzi.

Uhlelo lwe-scaffolding noma ama-scaffold amashubhu ayizicaffold ezakhiwe ngamashubhu e-aluminium noma ensimbi ahlanganiswe ndawonye yi-coupler ethembele ekungqubuzaneni ukuze isekele ukulayisha.

Izinzuzo zepayipi lensimbi elakhiwe nge-galvanized:

Ipayipi lensimbi elihlanganisiwe ligcina izinzuzo eziningi, lisetshenziswa kahle ezindaweni ezigqwala kakhulu.

Izinzuzo eziyinhloko zepayipi lesakhiwo elihlanganisiwe zifaka:

- Kuvikela ekugqwaleni nasekugqwaleni

- Ukwanda kwesikhathi eside kwesakhiwo

- Ukuthembeka okuthuthukisiwe okuphelele

- Isivikelo esingabizi

- Kulula ukuhlola

- Ukulungiswa okuncane

- Ukuqina okuqinile

- Kulula ukunakekela kunezipayipi ezijwayelekile ezipendiwe

- Kuvikelwe yi-ASTM standardization ethuthukisiwe

Amapayipi Ensimbi Ahlanganisiwe Izicelo:

- Ipayipi lensimbi elihlanganisiwe liyisinqumo esihle kakhulu sezinhlelo zokusebenza eziningi kanye namasu okucubungula.

Ezinye izinhlelo zokusebenza ezivamile zamapayipi ensimbi agqitshiwe zifaka:

- Ukuhlanganiswa kwamapayipi

- Amaphrojekthi okwakha

- Ukuthuthwa koketshezi okushisayo nokubandayo

- Ama-Bollards

- Izindawo eziveziwe ezisetshenzisiwe ngamapayipi

- Amapayipi asetshenzisiwe ezindaweni zasolwandle

- Izinsika noma Izinsika Zokuphatha

- Izigxobo Zocingo Nocingo

- Ipayipi elihlanganisiwe lingasikwa, lishiswe, noma lifakwe izinti ngesivikelo esifanele.

Ipayipi lesakhiwo elihlanganisiwe lensimbi lingasetshenziswa futhi ezinhlotsheni eziningi zezicelo lapho kudingeka khona ukumelana nokugqwala.

Imininingwane

| I-API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| I-API 5CT: J55, K55, N80, L80, P110 |

| I-ASTM A252: GR.1, GR.2, GR.3 |

| I-EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-ASTM A53/A53M: GR.A, GR.B |

| I-BS 1387: Ibanga A, Ibanga B |

| I-ASTM A135/A135M: GR.A, GR.B |

| EN 10217: P195TR1 / P195TR2, P235TR1 / P235TR2, P265TR1 / P265TR2 |

| I-DIN 2458: St37.0, St44.0, St52.0 |

| I-AS/NZS 1163: Ibanga C250 , Ibanga C350, Ibanga C450 |

| I-SANS 657-3: 2015 |

Okujwayelekile kanye neBanga

| BS1387 | I-scaffolding yamasimu okwakha |

| I-API 5L PSL1/PSL2 Gr.A, Gr.B, X42, X46, X52, X56, X60, X65, X70 | Amapayipi e-ERW kawoyela wokuthutha, igesi yemvelo |

| I-ASTM A53: GR.A, GR.B | Amapayipi Ensimbi e-ERW okwakha nokwakha |

| I-ASTM A252 I-ASTM A178 | Amapayipi Ensimbi e-ERW okwakha amaphrojekthi okwakha |

| I-AN/NZS 1163 I-AN/NZS 1074 | Amapayipi Ensimbi e-ERW amaphrojekthi okwakha izakhiwo |

| EN10219-1 S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H | Amapayipi e-ERW asetshenziselwa ukuhambisa uketshezi ngokucindezela okuphansi/okuphakathi njengowoyela, igesi, umusi, amanzi, umoya |

| I-ASTM A500/501, i-ASTM A691 | Amapayipi e-ERW okuhambisa uketshezi |

| I-EN10217-1, S275, S275JR, S355JRH, S355J2H | |

| I-ASTM A672 | Amapayipi e-ERW okusetshenziswa ngomfutho ophezulu |

| I-ASTM A123/A123M | ukugqoka okufakwe ngogesi okushisayo emikhiqizweni yensimbi engagqwali kanye nensimbi eqinisiwe |

| I-ASTM A53/A53M: | ipayipi lensimbi elimnyama elingenamthungo nelihlanganisiwe elimnyama, elifakwe ngogesi oshisayo kanye nelimbozwe ngomnyama ngenhloso evamile. |

| I-EN 10240 | kwezembozo zensimbi, okuhlanganisa nokufaka i-galvanizing, zamapayipi ensimbi angenamthungo nahlanganisiwe. |

| I-EN 10255 | ukudlulisa uketshezi olungeyona ingozi, okuhlanganisa noqweqwe olufakwe i-hot-dip galvanized. |

Ikhwalithi yokulawula

Ukuhlolwa Kwezinto Ezingavuthiwe, Ukuhlaziywa Kwamakhemikhali, Ukuhlolwa Kwemishini, Ukuhlolwa Okubonakalayo, Ukuhlolwa Kokucindezeleka, Ukuhlolwa Kobukhulu, Ukuhlolwa Kokugoba, Ukuhlolwa Kokuthamba, Ukuhlolwa Komthelela, Ukuhlolwa Kwe-DWT, Ukuhlolwa Kwe-NDT, Ukuhlolwa Kwamanzi, Ukuhlolwa Kokuqina…..

Ukumaka, Ukupenda ngaphambi kokulethwa.

Ukupakisha Nokuthumela

Indlela yokufaka amapayipi ensimbi ihilela ukuhlanza, ukuqoqa, ukugoqa, ukubopha, ukubopha, ukulebula, ukufaka amaphalethi (uma kudingeka), ukufaka amabhokisi, ukuvala, ukuvala, ukuhambisa, kanye nokukhipha. Izinhlobo ezahlukene zamapayipi ensimbi nezinsimbi ezinezindlela ezahlukene zokupakisha. Le nqubo ephelele iqinisekisa ukuthi amapayipi ensimbi athunyelwa futhi afike lapho eya khona esesimweni esihle kakhulu, elungele ukusetshenziswa kwawo okuhlosiwe.

Ukusetshenziswa Nokusetshenziswa

Ipayipi elihlanganisiwe liyipayipi lensimbi elifakwe i-hot-dip galvanized futhi lambozwa ngesendlalelo se-zinc ukuze kuthuthukiswe ukumelana nokugqwala kwayo kanye nokuphila kwayo kwenkonzo. Ipayipi elihlanganisiwe linokusetshenziswa okubanzi ezindaweni ezahlukahlukene, okuhlanganisa kodwa kungagcini lapho:

1. Insimu yokwakha:

Amapayipi agqitshwe nge-galvanized avame ukusetshenziswa ezakhiweni zokwakha, njengezinsika zezitebhisi, izinsimbi zokubiyela, ozimele besakhiwo sensimbi, njll. Ngenxa yokumelana nokugqwala kwengqimba ye-zinc, amapayipi agqitshwe nge-galvanized angasetshenziswa ngaphandle nasezindaweni ezinomswakama isikhathi eside futhi awakwazi ukugqwala.

2. Izinhlelo zokuphakelwa kwamanzi kanye nokukhipha amanzi:

Amapayipi e-galvanized asetshenziswa kabanzi ezinhlelweni zokuhlinzeka ngamanzi kanye nezinhlelo zokukhipha amanzi ukuze kuthuthwe amanzi okuphuza, amanzi ezimboni kanye nendle. Ukumelana kwawo nokugqwala kwenza kube ukukhetha okuthembekile kokunciphisa ukuvaleka kwamapayipi nezinkinga zokugqwala.

3. Ukudluliswa kukawoyela negesi:

Ipayipi elihlanganisiwe livame ukusetshenziswa ezinhlelweni zamapayipi ezithutha uwoyela, igesi yemvelo, kanye nolunye uketshezi noma amagesi. Ungqimba lwezinki luvikela amapayipi ekugqwaleni nasekungcoleni kwemvelo.

4. Izinhlelo ze-HVAC:

Amapayipi agqitshwe nge-galvanized nawo asetshenziswa ezinhlelweni zokushisa, zokungenisa umoya kanye nezokupholisa umoya. Njengoba lezi zinhlelo zibhekene nezimo ezahlukahlukene zemvelo, ukumelana nokugqwala kwepayipi eligqitshwe nge-galvanized kungandisa isikhathi salo sokusebenza.

5. Izinsika Zokuvikela Umgwaqo:

Amapayipi agqitshwe nge-galvanized avame ukusetshenziselwa ukukhiqiza izivikelo zomgwaqo ukuze kuqinisekiswe ukuphepha kwethrafikhi kanye nokumaka imingcele yomgwaqo.

6. Umkhakha Wezimayini Nezimboni:

Emkhakheni wezimayini kanye nezimboni, amapayipi agqitshwe nge-galvanized asetshenziselwa ukuthutha i-ore, izinto zokusetshenziswa, amakhemikhali, njll. Ukumelana kwayo nokugqwala kanye nezakhiwo zayo zamandla kwenza ifaneleke ukusetshenziswa kulezi zindawo ezinzima.

7. Amasimu ezolimo:

Amapayipi afakwe ugesi avame ukusetshenziswa emasimini ezolimo, njengamapayipi ezinhlelo zokunisela epulazini, ngenxa yamandla awo okumelana nokugqwala enhlabathini.

Ngamafuphi, amapayipi agqitshwe nge-galvanized anezicelo ezibalulekile emikhakheni eminingi ehlukene, kusukela ekwakheni kuya engqalasizinda kuya ezimbonini nakwezolimo ngenxa yokumelana kwawo nokugqwala kanye nokuguquguquka.

Amapayipi ensimbi asebenza njengomgogodla wobunjiniyela bezimboni kanye nobezokwakha banamuhla, esekela izinhlelo zokusebenza eziningi ezifaka isandla ekuthuthukisweni kwemiphakathi kanye nomnotho emhlabeni jikelele.

Amapayipi ensimbi kanye nezinto zokufakelwa esizikhiqizele iWomic Steel ezisetshenziswa kabanzi kumapayipi kaphethiloli, igesi, uphethiloli kanye namanzi, amaphrojekthi okwakha amachweba olwandle kanye nokwakha, ukumba, insimbi yesakhiwo, amaphrojekthi okwakha amapulangwe kanye namabhuloho, kanye namapayipi ensimbi anembile okukhiqiza amarola okuhambisa, njll.