Incazelo Yomkhiqizo

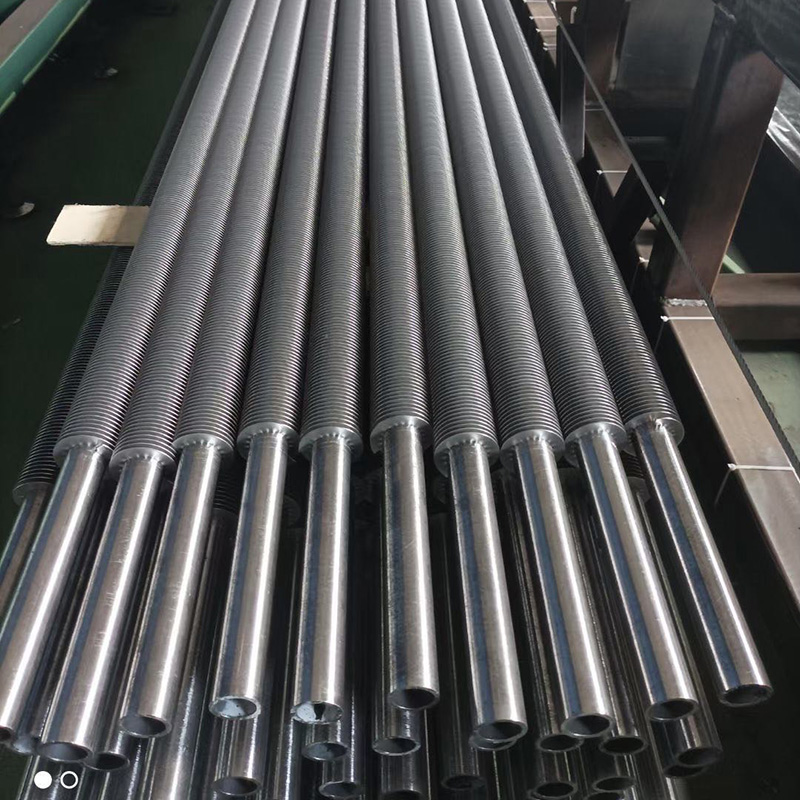

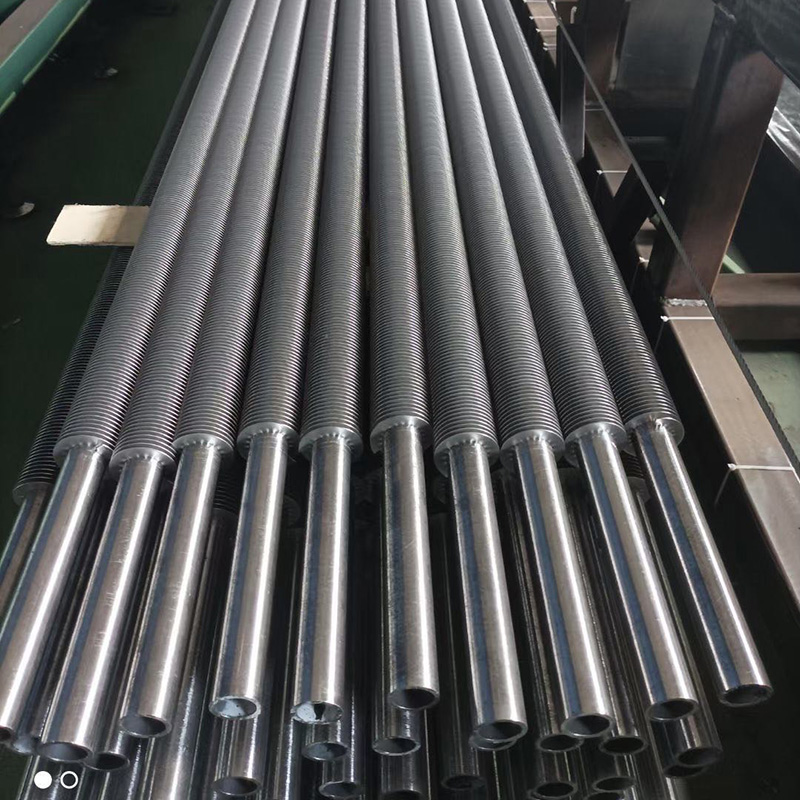

Imininingwane yepayipi lebhoyila lensimbi enobukhulu obuphelele (njengobubanzi noma ubude) kanye nobukhulu bodonga, ipayipi lebhoyila lensimbi lingasetshenziswa epayipini, imishini yobuchwepheshe bokushisa, imishini yezimboni, ukuhlola kwe-petroleum geological, izitsha, imboni yamakhemikhali, kanye neminye imisebenzi ekhethekile.

Amapayipi ebhoyila ensimbi akhiqizwa ngamapayipi angenamthungo, enziwe ngezinto zensimbi yekhabhoni noma ngensimbi ye-alloy. Amapayipi ebhoyila asetshenziswa kabanzi kuma-boilers anomusi, kuma-heat exchangers, ekuhlanganiseni amandla, ezitshalweni zikaphethiloli, ezitshalweni zokucubungula izimboni, ezitshalweni zikagesi, ezigayweni zokukhiqiza ushukela njll. Amapayipi ebhoyila noma amapayipi avame ukusetshenziswa njengebhoyila enomfutho ophakathi noma amapayipi ebhoyila anomfutho ophezulu.

Imininingwane

| I-ASTM A179 |

| I-ASTM A192 |

| I-ASTM A209: Gr.T1, Gr. T1a, Gr. T1b |

| I-ASTM A210:Gr.A1, Gr.C |

| I-ASTM A106: Gr.A, Gr.B, Gr.C |

| I-DIN 17175: ST35.8, ST45.8, 15Mo3, 13CrMo44 |

| I-EN 10216-2: P235GH, P265GH, 16Mo3, 10CrMo5-5, 13CrMo4-5 |

| I-API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| I-ASTM A178:Gr.A, Gr.C |

| I-ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| I-ASTM A333: Ibanga 1, Ibanga 3, Ibanga 4, Ibanga 6, Ibanga 7, Ibanga 8, Ibanga 9. Ibanga 10, Ibanga 11 |

| I-ASTM A312/A312M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H njll.... |

| I-ASTM A269/A269M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H njll.... |

| EN 10216-5:1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 |

Okujwayelekile kanye neBanga

Amashubhu ebhoyila ajwayelekileAmabanga:

ASME SA-179M, ASME SA-106, ASTM A178, ASME SA-192M, EN10216-1, JIS G3461, ASME SA-213M, DIN17175, DIN1629.

Isimo Sokulethwa: Kufakwe i-Anneal, kujwayelekile, kuthambile. Kufakwe uwoyela ebusweni, kupendwe ngombala omnyama, kuqhunyiswe ngesibhamu, kufakwe nge-galvanized eshisayo.

| I-ASME SA-179M: | Isishintshi Sokushisa Sensimbi Ephansi Edonswa Ngobandayo kanye Namashubhu E-Condenser. |

| I-ASME SA-106: | Ipayipi Lensimbi Yekhabhoni Lensizakalo Yokushisa Okuphezulu. |

| I-ASTM A178: | Insimbi Yekhabhoni Ehlanganisiwe Emelana Nogesi kanye Nebhoyila Yensimbi Yekhabhoni Ehlanganisiwe kanye Namashubhu E-Superheater. |

| I-ASME SA-192M: | Amashubhu e-Carbon Steel Boiler angenamthungo amadivayisi acindezelwe kakhulu. |

| I-ASME SA-210M: | Ibhoyila Yensimbi Yekhabhoni Ephakathi Engenamthungo Namashubhu E-Superheater. |

| EN10216-1/2: | Amashubhu ensimbi angenamthungo angenamthungo ngezinjongo zokucindezela anezakhiwo ezithile zokushisa kwegumbi. |

| I-JIS G3454: | Amapayipi ensimbi yekhabhoni ukuze asebenze ekucindezelweni ezingeni lokushisa eliphakeme cishe elingama-degree Celsius angu-350 |

| I-JIS G3461: | Amapayipi Ensimbi Yekhabhoni E-Boiler kanye ne-Heat Exchanger. |

| I-GB 5310: | Amapayipi ensimbi angenamthungo kanye namapayipi ebhoyila enomfutho ophezulu. |

| I-ASME SA-335M: | Ibhoyila yensimbi ye-ferritic ne-austenitic alloy engenamthungo, i-superheater kanye ne-heat-exchange tube. |

| I-ASME SA-213M: | Amashubhu Ensimbi Engxubevange yama-boiler, ama-superheater kanye nama-heat exchanger. |

| I-DIN 17175: | Amapayipi Ensimbi Angenamthungo Embonini Yamabhoyila, ipayipi lensimbi elingenamthungo elimelana nokushisa, elisetshenziselwa amapayipi embonini yamabhoyila. |

| I-DIN 1629: | Ama-boiler ashisa kakhulu, amapayipi okukhiqiza, imikhumbi, imishini, ukufakwa kwamapayipi, kanye nezishintshi zokushisa ngamapayipi e-austenitic. |

Ikhwalithi yokulawula

Ukuhlolwa Kwezinto Ezingavuthiwe, Ukuhlaziywa Kwamakhemikhali, Ukuhlolwa Kwemishini, Ukuhlolwa Okubonakalayo, Ukuhlolwa Kokucindezeleka, Ukuhlolwa Kobukhulu, Ukuhlolwa Kokugoba, Ukuhlolwa Kokuthamba, Ukuhlolwa Komthelela, Ukuhlolwa Kwe-DWT, Ukuhlolwa Kwe-NDT, Ukuhlolwa Kwamanzi, Ukuhlolwa Kokuqina…..

Ukumaka, Ukupenda ngaphambi kokulethwa.

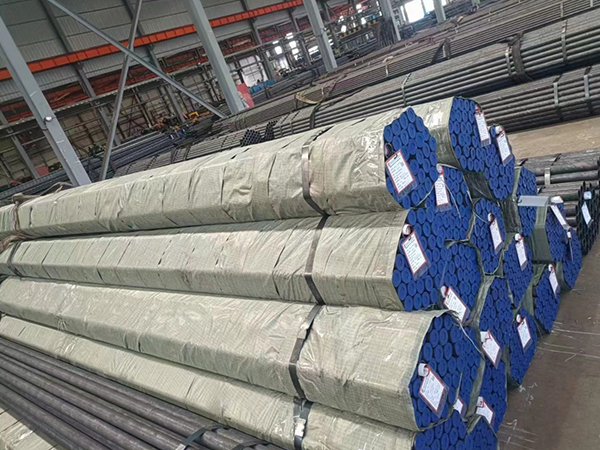

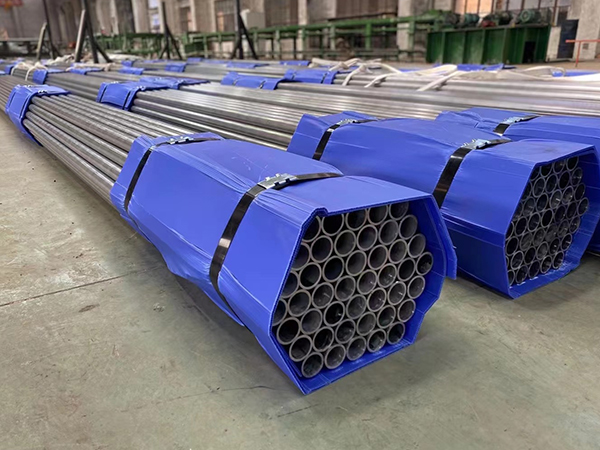

Ukupakisha Nokuthumela

Indlela yokufaka amapayipi ensimbi ihilela ukuhlanza, ukuqoqa, ukugoqa, ukubopha, ukubopha, ukulebula, ukufaka amaphalethi (uma kudingeka), ukufaka amabhokisi, ukuvala, ukuvala, ukuhambisa, kanye nokukhipha. Izinhlobo ezahlukene zamapayipi ensimbi nezinsimbi ezinezindlela ezahlukene zokupakisha. Le nqubo ephelele iqinisekisa ukuthi amapayipi ensimbi athunyelwa futhi afike lapho eya khona esesimweni esihle kakhulu, elungele ukusetshenziswa kwawo okuhlosiwe.

Ukusetshenziswa Nokusetshenziswa

Amapayipi ensimbi asebenza njengomgogodla wobunjiniyela bezimboni kanye nobezokwakha banamuhla, esekela izinhlelo zokusebenza eziningi ezifaka isandla ekuthuthukisweni kwemiphakathi kanye nomnotho emhlabeni jikelele.

Amapayipi ensimbi kanye nezinto zokufakelwa esizikhiqizele iWomic Steel ezisetshenziswa kabanzi kumapayipi kaphethiloli, igesi, uphethiloli kanye namanzi, amaphrojekthi okwakha amachweba olwandle kanye nokwakha, ukumba, insimbi yesakhiwo, amaphrojekthi okwakha amapulangwe kanye namabhuloho, kanye namapayipi ensimbi anembile okukhiqiza amarola okuhambisa, njll.