Incazelo Yomkhiqizo

Isinciphisi:

Isinciphisi sepayipi lensimbi sisebenza njengengxenye ebalulekile yepayipi, okuvumela ukuguquka okungenamthungo kusuka kosayizi abakhulu kuya kwabancane ngokuhambisana nemininingwane yobubanzi bangaphakathi.

Kunezinhlobo ezimbili eziyinhloko zama-reducer: aqinile kanye nangaphandle. Ama-reducer aqinile enza ukunciphisa usayizi we-bore olinganayo, okuqinisekisa ukuhambisana kwemigqa ephakathi yamapayipi axhunyiwe. Lokhu kulungiselelwa kufanelekile lapho ukugcina amazinga okugeleza afanayo kubalulekile. Ngokuphambene nalokho, ama-reducer angavamile ethula i-offset phakathi kwemigqa ephakathi yamapayipi, ehlangabezana nezimo lapho amazinga oketshezi edinga ukulingana phakathi kwamapayipi aphezulu naphansi.

I-Eccentric Reducer

I-Concentric Reducer

Ama-reducer adlala indima yokuguqula ekucushweni kwamapayipi, okwenza kube lula ukushintshashintsha okubushelelezi phakathi kwamapayipi anobukhulu obuhlukahlukene. Lokhu kuthuthukisa kuthuthukisa ukusebenza kahle kwesistimu kanye nokusebenza kwayo yonke.

Indololwane:

Ingqiniba yepayipi lensimbi inendima ebalulekile ezinhlelweni zamapayipi, ikhuthaza izinguquko endleleni yokugeleza koketshezi. Isebenza ekuxhumeni amapayipi anobubanzi obufanayo noma obuhlukahlukene, iqondisa kahle ukugeleza emigwaqweni efiselekayo.

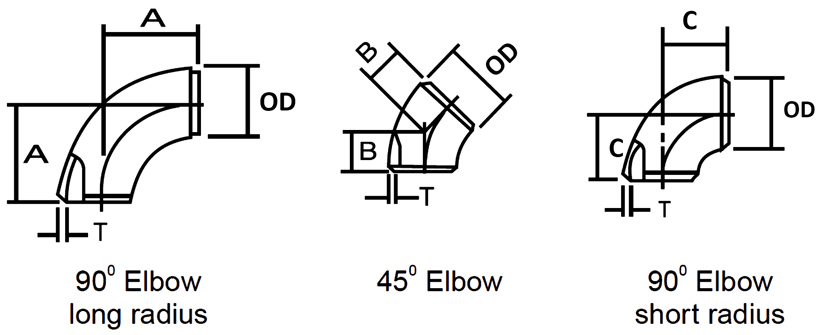

Izindololwane zihlukaniswa ngokwezinga lokushintsha koketshezi oluvela emipayipini. Ama-engeli avame ukuhlangatshezwa afaka ama-degree angu-45, ama-degree angu-90, kanye nama-degree angu-180. Ngezinhlelo ezikhethekile, ama-engeli anjenge-degrees angu-60 kanye nama-degrees angu-120 ayasetshenziswa.

Izindololwane zihlukaniswa ngezigaba ezihlukene ngokusekelwe kububanzi bazo obuhambisana nobubanzi bepayipi. I-Short Radius Elbow (SR elbow) ine-radius elingana nobubanzi bepayipi, okwenza ifaneleke kumapayipi anengcindezi ephansi, anesivinini esiphansi, noma ezindaweni ezivalekile lapho ukuvuleka kusezingeni eliphezulu. Ngokuphambene nalokho, i-Long Radius Elbow (LR elbow), ene-radius ephindwe ka-1.5 kunobubanzi bepayipi, isetshenziswa kumapayipi anengcindezi ephezulu kanye nesivinini sokugeleza okuphezulu.

Izindololwane zingahlukaniswa ngokwezindlela zazo zokuxhuma amapayipi—I-Butt Welded Elbow, I-Socket Welded Elbow, kanye ne-Threaded Elbow. Lezi zinhlobo zinikeza ukuguquguquka okusekelwe ohlotsheni lwejoyinti olusetshenziswayo. Ngokwezinto ezibonakalayo, izindololwane zenziwe ngensimbi engagqwali, insimbi yekhabhoni, noma insimbi ye-alloy, ezivumelana nezidingo zomzimba we-valve ethile.

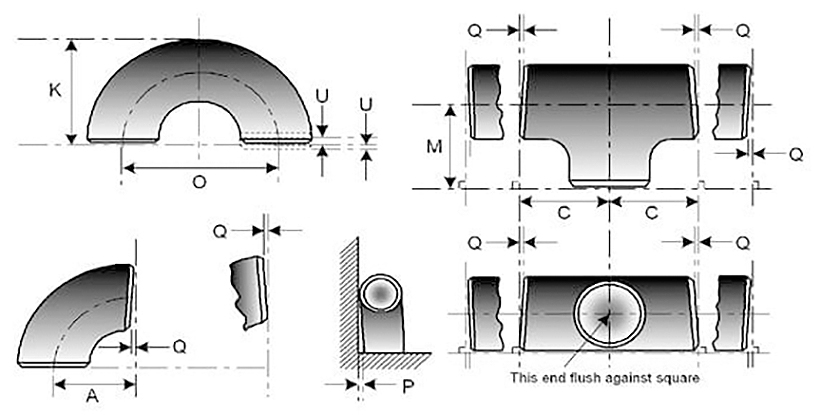

I-tee:

Izinhlobo ze-Steel Pipe Tee:

● Ngokusekelwe kububanzi begatsha kanye nemisebenzi:

● I-Equal Tee

● I-Tee Yokunciphisa (I-Tee Yokunciphisa)

Ngokusekelwe Ezinhlotsheni Zokuxhumana:

● I-Butt Weld Tee

● I-Socket Weld Tee

● I-T-shirt Enentambo

Ngokusekelwe Ezinhlotsheni Zezinto:

● I-Carbon Steel Pipe Tee

● I-Alloy Steel Tee

● I-T-Shirt Engagqwali

Izicelo ze-Steel Pipe Tee:

● Ama-tee epayipi lensimbi ayizinto ezisebenziseka kalula ezithola ukusetshenziswa ezimbonini ezahlukahlukene ngenxa yekhono lazo lokuxhuma nokuqondisa ukugeleza ngezindlela ezahlukene. Ezinye izinhlelo zokusebenza ezivamile zifaka:

● Ukuthunyelwa Kwamafutha Negesi: Ama-Tee asetshenziselwa ukuhlukanisa amapayipi okuthutha uwoyela negesi.

● Ukuhluzwa Kwe-Petroleum No-Oyili: Ezindaweni zokuhluzwa, ama-tee asiza ekuphatheni ukugeleza kwemikhiqizo ehlukene ngesikhathi sezinqubo zokuhluzwa.

● Izinhlelo Zokwelapha Amanzi: Ama-Tee asetshenziswa ezitshalweni zokwelapha amanzi ukulawula ukugeleza kwamanzi namakhemikhali.

● Izimboni Zamakhemikhali: Ama-Tee adlala indima ekucutshungulweni kwamakhemikhali ngokuqondisa ukugeleza kwamakhemikhali nezinto ezahlukene.

● Amapayipi Okuhlanzeka: Ezimbonini zokudla, zemithi, nakwezinye izindawo, ama-tee amapayipi okuhlanzeka asiza ekugcineni izimo zokuhlanzeka lapho kuthuthwa uketshezi.

● Iziteshi Zikagesi: Ama-Tee asetshenziswa ezinhlelweni zokuphehla nokusabalalisa ugesi.

● Imishini Nemishini: Ama-Tee ahlanganiswe nemishini ehlukahlukene yezimboni kanye nemishini yokuphathwa koketshezi.

● Ama-Heat Exchanger: Ama-Tee asetshenziswa ezinhlelweni zokushintshanisa ukushisa ukulawula ukugeleza koketshezi olushisayo nolubandayo.

Ama-tee epayipi lensimbi ayizingxenye ezibalulekile ezinhlelweni eziningi, ahlinzeka ngokuguquguquka nokulawula ukusatshalaliswa kanye nesiqondiso soketshezi. Ukukhethwa kwezinto kanye nohlobo lwe-tee kuncike ezintweni ezifana nohlobo loketshezi oluthuthwayo, ingcindezi, izinga lokushisa, kanye nezidingo ezithile zohlelo lokusebenza.

Ukubuka Konke Kwesivalo Sepayipi Lensimbi

Isivalo sepayipi lensimbi, esibizwa nangokuthi ipulaki lensimbi, siyisivalo esisetshenziselwa ukumboza ukuphela kwepayipi. Singashintshwa siye ekugcineni kwepayipi noma sinamathiselwe entanjeni yangaphandle yepayipi. Izivalo zepayipi lensimbi zisebenza ngenhloso yokumboza nokuvikela izivalo zepayipi. Lezi zivalo ziza ngezimo ezahlukene, kufaka phakathi izivalo ze-hemispherical, elliptical, dish, kanye neziyindilinga.

Izimo Zezigqoko Eziyindilinga:

● Isivalo Esiphezulu

● Ikepisi Eliyindilinga

● Isivalo Sezitsha

● Isivalo Esiyindilinga

Ukwelashwa Kokuxhumeka:

Ama-cap asetshenziselwa ukusika ukuguquka nokuxhumeka emapayipini. Ukukhetha ukwelashwa kokuxhumeka kuncike ezidingweni ezithile zohlelo lokusebenza:

● Ukuxhumeka Kwe-Butt Weld

● Ukuxhumeka Kokushisela Kwesokhethi

● Uxhumano Olunezintambo

Izicelo:

Izivalo zokugcina zinezindlela eziningi zokusetshenziswa kuzo zonke izimboni ezifana namakhemikhali, ezokwakha, iphepha, usimende, kanye nokwakha imikhumbi. Ziwusizo kakhulu ekuxhumeni amapayipi anobubanzi obuhlukene kanye nokunikeza isithiyo esivikelayo ekugcineni kwepayipi.

Izinhlobo Zesivalo Sepayipi Sensimbi:

Izinhlobo Zokuxhumana:

● Isivalo Sokushisela Izinqe

● Isivalo Sokushisela Isokhethi

● Izinhlobo zezinto:

● Isembozo Sepayipi Lensimbi Yekhabhoni

● Isivalo Sensimbi Engagqwali

● Isivalo Sensimbi Ehlanganisiwe

Ukubuka Konke Kwepayipi Lensimbi

Ukugoba kwepayipi lensimbi uhlobo lokufakwa kwepayipi olusetshenziselwa ukushintsha indlela ipayipi elihamba ngayo. Nakuba kufana nendololwane yepayipi, ukugoba kwepayipi kukude futhi kuvame ukukhiqizwa ngokwezidingo ezithile. Ukugoba kwepayipi kuza ngobukhulu obuhlukahlukene, ngamazinga ahlukene okugoba, ukuze kuhlangatshezwane nama-engeli ahlukene okujika emapayipini.

Izinhlobo Zokugoba Nokusebenza Kahle:

Ukugoba kwe-3D: Ukugoba okune-radius ephindwe kathathu kunobubanzi bepayipi obujwayelekile. Kuvame ukusetshenziswa kumapayipi amade ngenxa yokugoba kwawo okuthambile kanye nokushintsha okusebenzayo kwendlela.

Ukugoba okungu-5D: Lokhu kugoba kunerediyasi ephindwe kahlanu kunobubanzi bepayipi obujwayelekile. Kuhlinzeka ngoshintsho olubushelelezi endleleni, okwenza kufaneleke kumapayipi anwetshiwe ngenkathi kugcinwa ukusebenza kahle kokugeleza koketshezi.

Ukubuyisela Izinguquko Zeziqu:

Ukugoba okungu-6D no-8D: Lokhu kugoba, okune-radii ephindwe kasithupha kanye nephindwe kasishiyagalombili ububanzi bepayipi elijwayelekile ngokulandelana, kusetshenziselwa ukukhokhela izinguquko ezincane ohlangothini lwepayipi. Kuqinisekisa ukuguquka kancane kancane ngaphandle kokuphazamisa ukugeleza.

Ukugoba kwamapayipi ensimbi kuyizinto ezibalulekile ezinhlelweni zamapayipi, okuvumela izinguquko eziqondisayo ngaphandle kokubangela ukuxokozela ngokweqile noma ukumelana nokugeleza koketshezi. Ukukhetha uhlobo lokugoba kuncike ezidingweni ezithile zepayipi, okuhlanganisa izinga lokushintsha kwendlela, isikhala esitholakalayo, kanye nesidingo sokugcina izici zokugeleza ezisebenza kahle.

Imininingwane

| I-ASME B16.9: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Yengxubevange |

| EN 10253-1: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

| I-JIS B2311: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

| I-DIN 2605: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Yengxubevange |

| I-GB/T 12459: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

Ubukhulu be-Pipe Elbow bumbozwe ku-ASME B16.9. Bheka ithebula elingezansi ukuze uthole ubukhulu be-elbow kusukela ku-1/2″ kuya ku-48″.

| USAYIZI WEPAYIPHI OLUNGAPHEZULU | Ububanzi bangaphandle | ISIKHUNGO ESIYA PHETHA | ||

| Intshi. | OD | A | B | C |

| 1/2 | 21.3 | 38 | 16 | – |

| 3/4 | 26.7 | 38 | 19 | – |

| 1 | 33.4 | 38 | 22 | 25 |

| 1 1/4 | 42.2 | 48 | 25 | 32 |

| 1 1/2 | 48.3 | 57 | 29 | 38 |

| 2 | 60.3 | 76 | 35 | 51 |

| 2 1/2 | 73 | 95 | 44 | 64 |

| 3 | 88.9 | 114 | 51 | 76 |

| 3 1/2 | 101.6 | 133 | 57 | 89 |

| 4 | 114.3 | 152 | 64 | 102 |

| 5 | 141.3 | 190 | 79 | 127 |

| 6 | 168.3 | 229 | 95 | 152 |

| 8 | 219.1 | 305 | 127 | 203 |

| 10 | 273.1 | 381 | 159 | 254 |

| 12 | 323.9 | 457 | 190 | 305 |

| 14 | 355.6 | 533 | 222 | 356 |

| 16 | 406.4 | 610 | 254 | 406 |

| 18 | 457.2 | 686 | 286 | 457 |

| 20 | 508 | 762 | 318 | 508 |

| 22 | 559 | 838 | 343 | 559 |

| 24 | 610 | 914 | 381 | 610 |

| 26 | 660 | 991 | 406 | 660 |

| 28 | 711 | 1067 | 438 | 711 |

| 30 | 762 | 1143 | 470 | 762 |

| 32 | 813 | 1219 | 502 | 813 |

| 34 | 864 | 1295 | 533 | 864 |

| 36 | 914 | 1372 | 565 | 914 |

| 38 | 965 | 1448 | 600 | 965 |

| 40 | 1016 | 1524 | 632 | 1016 |

| 42 | 1067 | 1600 | 660 | 1067 |

| 44 | 1118 | 1676 | 695 | 1118 |

| 46 | 1168 | 1753 | 727 | 1168 |

| 48 | 1219 | 1829 | 759 | 1219 |

| Zonke izilinganiso zingu-mm | ||||

Ubukhulu Bokufakwa Kwamapayipi Ukubekezelela ngokwe-ASME B16.9

| USAYIZI WEPAYIPHI OLUNGAPHEZULU | KONKE UKUFAKWA | KONKE UKUFAKWA | KONKE UKUFAKWA | IZINDLOVU NEZINTO EZINAMATHENI | UKUGOBA OKUBUYISAYO KWAMA-DEG angu-180 | UKUGOBA OKUBUYISAYO KWAMA-DEG angu-180 | UKUGOBA OKUBUYISAYO KWAMA-DEG angu-180 | ABANCIPHISI |

I-CAPS |

| I-NPS | I-OD eBevel (1), (2) | I-ID Ekupheleni | Ubukhulu Bodonga (3) | Ubukhulu obuphakathi kuya ekugcineni A,B,C,M | Ukusuka Ephakathi Kuya Esikhungweni O | Ukubuyelana Ubuso K | Ukuqondaniswa Kweziphetho U | Ubude obuphelele H | Ubude obuphelele E |

| ½ kuya ku-2½ | 0.06 | 0.03 | Okungenani ngaphansi kuka-87.5% wobukhulu obujwayelekile | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 |

| 3 kuya ku-3 ½ | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 4 | 0.06 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.12 | |

| 5 kuya ku-8 | 0.09 | 0.06 | 0.06 | 0.25 | 0.25 | 0.03 | 0.06 | 0.25 | |

| 10 kuya ku-18 | 0.16 | 0.12 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| 20 kuya ku-24 | 0.25 | 0.19 | 0.09 | 0.38 | 0.25 | 0.06 | 0.09 | 0.25 | |

| 26 kuya ku-30 | 0.25 | 0.19 | 0.12 | … | … | … | 0.19 | 0.38 | |

| 32 kuya ku-48 | 0.25 | 0.19 | 0.19 | … | … | … | 0.19 | 0.38 |

| USAYIZI WEPAYIPHI OLUNGAPHEZULU I-NPS | UKUBEKEZELELA KWE-ANGULARITY | UKUBEKEZELELA KWE-ANGULARITY | BONKE UBUNINGI BUNIKWA NGAMA-INCHI. UKUBEKELELANA KUYALINGANA FUTHI KUNCI NGAPHANDLE KWALOKHO OKUPHAWULWE. |

|

| I-Angle Q Engasebenzi | Ngaphandle Kwendiza P | (1) I-Out-of-round iyisamba samanani aphelele okubekezelelana kwe-plus kanye ne-minus. (2) Lokhu kubekezelelana kungenzeka kungasebenzi ezindaweni eziseduze zezingxenye ezakhiwe lapho kudingeka khona ubukhulu bodonga obuningi ukuze kuhlangatshezwane nezidingo zomklamo we-ASME B16.9. (3) Ububanzi bangaphakathi kanye nobukhulu bodonga obujwayelekile emaphethelweni kufanele kuchazwe ngumthengi. (4) Ngaphandle kokuthi kuchazwe ngenye indlela ngumthengi, lokhu kubekezelelana kusebenza kububanzi obungaphakathi obujwayelekile, obulingana nomehluko phakathi kobubanzi obungaphandle obujwayelekile kanye nobukhulu bodonga obuphindwe kabili. |

| ½ kuya ku-4 | 0.03 | 0.06 | |

| 5 kuya ku-8 | 0.06 | 0.12 | |

| 10 kuya ku-12 | 0.09 | 0.19 | |

| 14 kuya ku-16 | 0.09 | 0.25 | |

| 18 kuya ku-24 | 0.12 | 0.38 | |

| 26 kuya ku-30 | 0.19 | 0.38 | |

| 32 kuya ku-42 | 0.19 | 0.50 | |

| 44 kuya ku-48 | 0.18 | 0.75 |

Okujwayelekile kanye neBanga

| I-ASME B16.9: Izinto Zokushisela Izinqe Ezibunjiwe Ezikhiqizwe Embonini | Izinto zokwakha: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

| I-EN 10253-1: Ukufakwa Kwepayipi Lokushisela Izinqe - Ingxenye 1: Insimbi Yekhabhoni Ebunjiwe Yokusetshenziswa Okuvamile Futhi Ngaphandle Kwezidingo Eziqondile Zokuhlola | Izinto zokwakha: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

| I-JIS B2311: Ukufakwa Kwepayipi Lokushisela Izinqe Zensimbi Ukuze Kusetshenziswe Okuvamile | Izinto zokwakha: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

| I-DIN 2605: Ukufakwa Kwepayipi Lokushisela Izinqe Zensimbi: Izindololwane Nokugoba Okune-Pressure Factor Encishisiwe | Izinto zokwakha: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

| I-GB/T 12459: Ukufakwa Kwepayipi Elingenamthungo Lokushisela Izinqe Zensimbi | Izinto zokwakha: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

Inqubo Yokukhiqiza

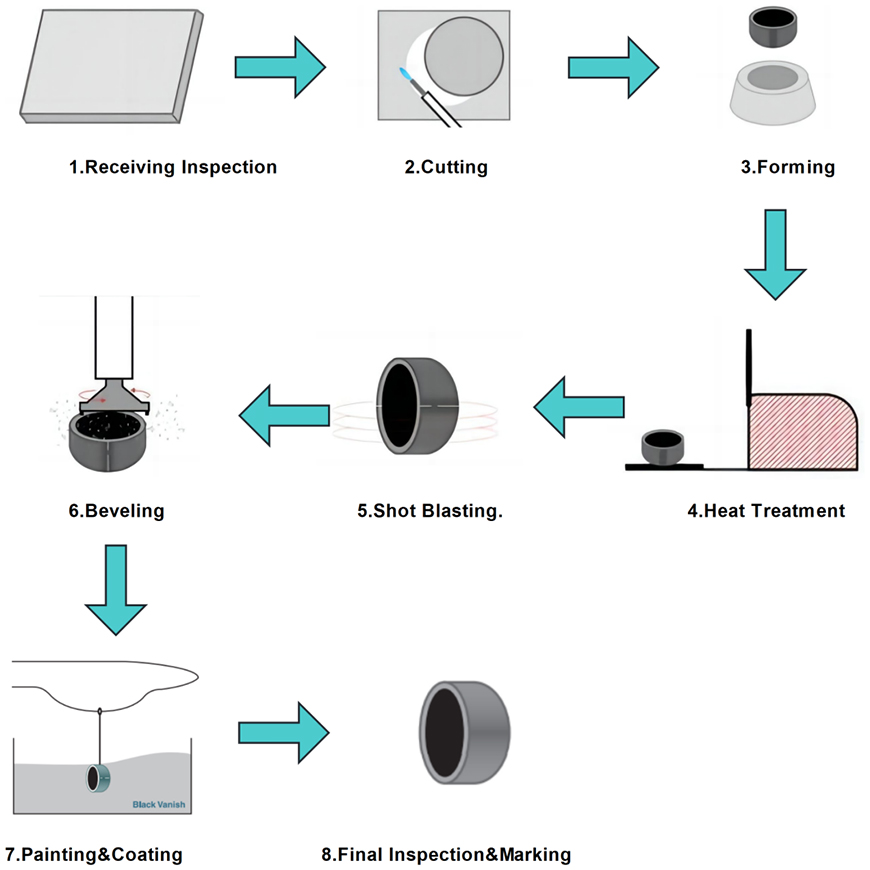

Inqubo Yokukhiqiza I-Cap

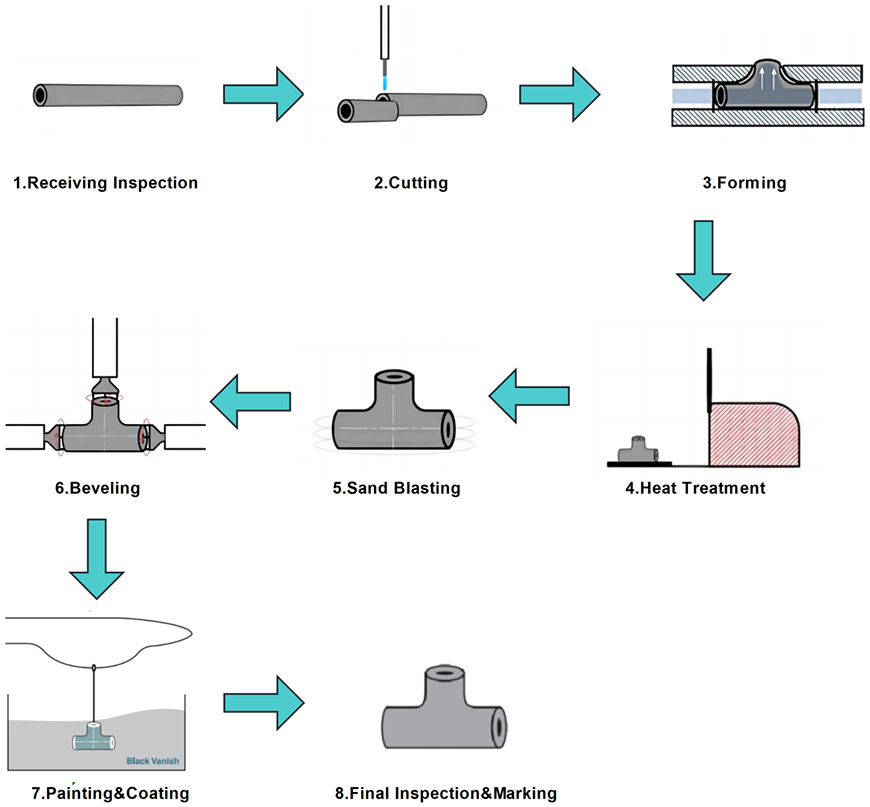

Inqubo Yokukhiqiza Ama-tee

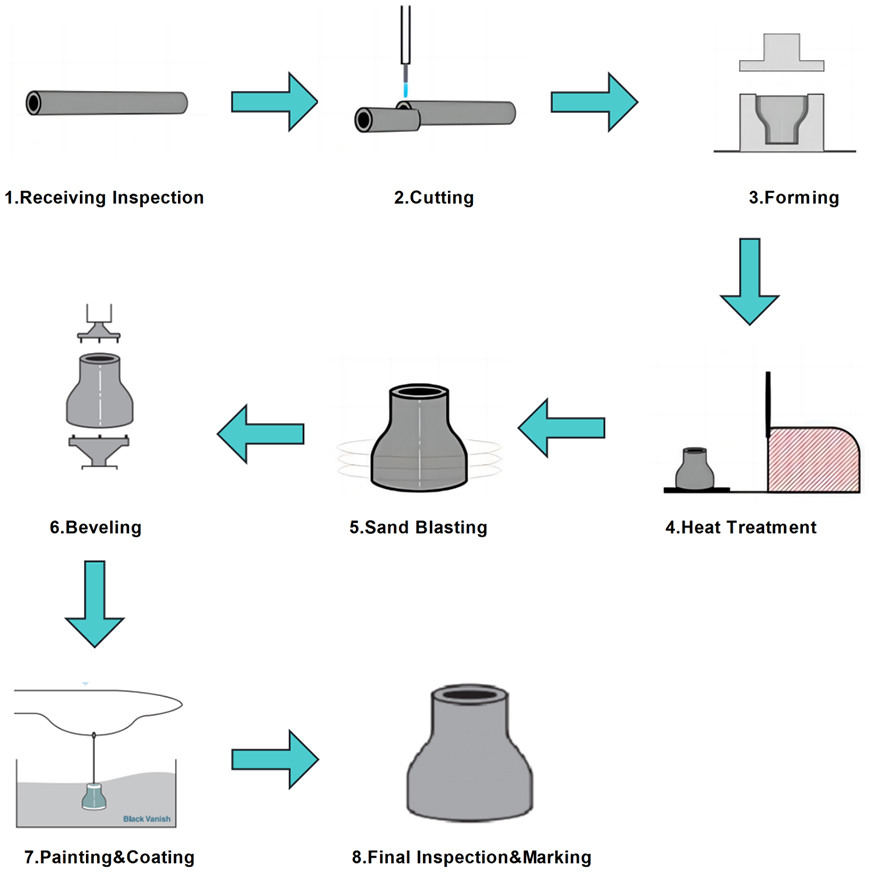

Inqubo Yokukhiqiza Yokunciphisa

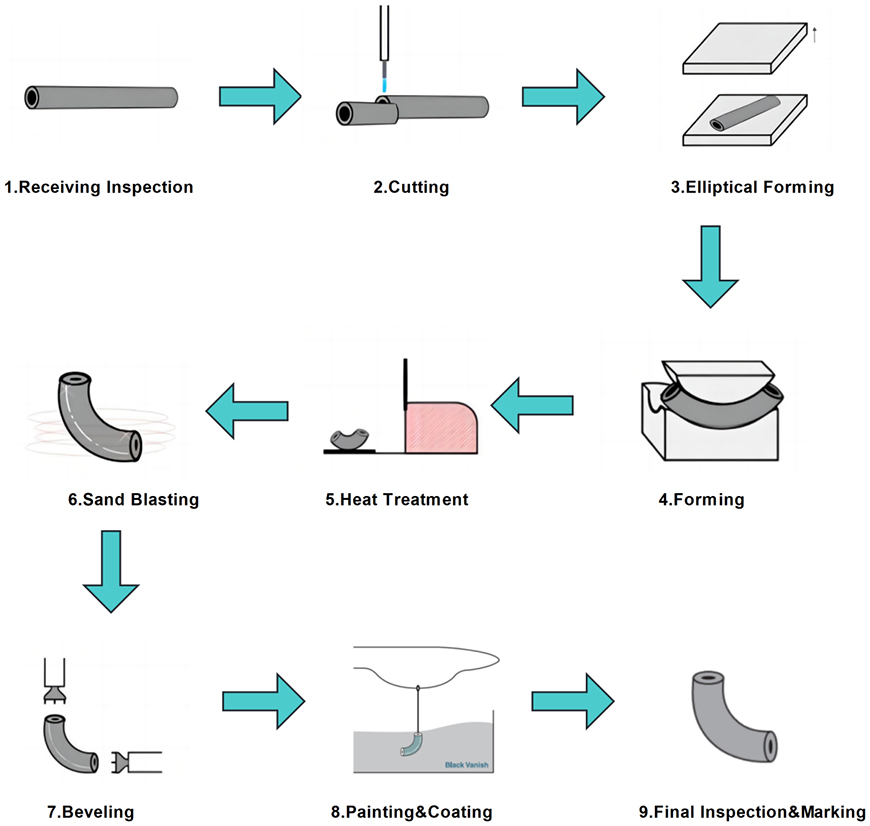

Inqubo Yokukhiqiza I-Elbow

Ikhwalithi yokulawula

Ukuhlolwa Kwezinto Ezingavuthiwe, Ukuhlaziywa Kwamakhemikhali, Ukuhlolwa Kwemishini, Ukuhlolwa Okubonakalayo, Ukuhlolwa Kobukhulu, Ukuhlolwa Kokugoba, Ukuhlolwa Kokuthamba, Ukuhlolwa Komthelela, Ukuhlolwa Kwe-DWT, Ukuhlolwa Okungonakalisi, Ukuhlolwa Kokuqina, Ukuhlolwa Kokucindezela, Ukuhlolwa Kokuvuza Kwesihlalo, Ukuhlolwa Kokusebenza Kokugeleza, Ukuhlolwa Kwe-Torque kanye Nokuthungwa, Ukuhlolwa Kokupenda Nokumboza, Ukubuyekezwa Kwamadokhumenti…..

Ukusetshenziswa Nokusetshenziswa

Ukuhlolwa Kwezinto Ezingavuthiwe, Ukuhlaziywa Kwamakhemikhali, Ukuhlolwa Kwemishini, Ukuhlolwa Okubonakalayo, Ukuhlolwa Kobukhulu, Ukuhlolwa Kokugoba, Ukuhlolwa Kokuthamba, Ukuhlolwa Komthelela, Ukuhlolwa Kwe-DWT, Ukuhlolwa Okungonakalisi, Ukuhlolwa Kokuqina, Ukuhlolwa Kokucindezela, Ukuhlolwa Kokuvuza Kwesihlalo, Ukuhlolwa Kokusebenza Kokugeleza, Ukuhlolwa Kwe-Torque kanye Nokuthungwa, Ukuhlolwa Kokupenda Nokumboza, Ukubuyekezwa Kwamadokhumenti…..

● Uxhumano

● Ukulawula Okuqondiswayo

● Ukulawulwa Kokugeleza

● Ukuhlukaniswa Kwabezindaba

● Ukuxuba Uketshezi

● Ukusekela kanye Nokuqinisa

● Ukulawula Izinga Lokushisa

● Ukuhlanzeka Nokungazali

● Ukuphepha

● Izinto Ezicatshangelwayo Zobuhle Nezemvelo

Ngamafuphi, ukufakwa kwamapayipi kuyizinto ezibalulekile ezivumela ukuthuthwa koketshezi namagesi ngendlela ephumelelayo, ephephile, nelawulwayo kuzo zonke izimboni. Ukusetshenziswa kwazo okuhlukahlukene kunegalelo ekuthembekeni, ekusebenzeni, nasekuphepheni kwezinhlelo zokuphatha uketshezi ezindaweni eziningi.

Ukupakisha Nokuthumela

KwaWomic Steel, siyaqonda ukubaluleka kokupakisha okuphephile kanye nokuthunyelwa okuthembekile uma kukhulunywa ngokuletha izinto zethu zokufaka amapayipi ezisezingeni eliphezulu emnyango wakho. Nasi isifinyezo sezinqubo zethu zokupakisha kanye nokuthumela ukuze ubhekisele kuzo:

Ukupakisha:

Izinto zethu zokufaka amapayipi zipakishwe ngokucophelela ukuqinisekisa ukuthi zifika kuwe zisesimweni esifanele, zilungele izidingo zakho zezimboni noma zezentengiselwano. Inqubo yethu yokupakisha ifaka phakathi lezi zinyathelo ezibalulekile ezilandelayo:

● Ukuhlolwa Kwekhwalithi: Ngaphambi kokupakisha, zonke izinto zokufaka amapayipi zihlolwa ngekhwalithi ephelele ukuqinisekisa ukuthi ziyahlangabezana nezindinganiso zethu eziqinile zokusebenza nobuqotho.

● Ukuvikela: Kuye ngohlobo lwezinto kanye nokusetshenziswa kwazo, izinto zethu zokufaka zingase zithole ukuvikela ukuvimbela ukugqwala kanye nomonakalo ngesikhathi sokuthuthwa.

● Ukubopha Okuphephile: Izinto zokubopha zihlanganiswa ndawonye ngokuphephile, okuqinisekisa ukuthi zihlala zizinzile futhi zivikelekile phakathi nenqubo yokuthumela.

● Ukulebula Nokubhala Imibhalo: Iphakheji ngayinye ibhalwe ngokucacile ngolwazi olubalulekile, okuhlanganisa imininingwane yomkhiqizo, ubuningi, kanye nanoma yimiphi imiyalelo ekhethekile yokuphatha. Imibhalo efanele, njengezitifiketi zokuthobela imithetho, nayo ifakiwe.

● Ukupakisha Ngokwezifiso: Singakwazi ukwamukela izicelo ezikhethekile zokupakisha ngokusekelwe ezidingweni zakho ezihlukile, siqinisekise ukuthi izinto zakho zilungiswa ngendlela efanele.

Ukuthunyelwa:

Sisebenzisana nabalingani bethu bokuthumela impahla abathembekile ukuqinisekisa ukulethwa okuthembekile nokufika ngesikhathi endaweni yakho ecacisiwe. Ithimba lethu lezokuthutha lenza ngcono imizila yokuthumela impahla ukuze linciphise izikhathi zokuhamba futhi linciphise ingozi yokubambezeleka. Ngokuthunyelwa kwamanye amazwe, siphatha yonke imibhalo yamasiko edingekayo kanye nokuhambisana nemithetho ukuze kube lula ukusulwa kwamasiko okushelelayo. Sinikeza izinketho zokuthumela eziguquguqukayo, okuhlanganisa nokuthunyelwa okusheshayo kwempahla ngezidingo eziphuthumayo.