Incazelo Yomkhiqizo

I-valve iyithuluzi eliyisisekelo lomshini elisetshenziselwa ukulawula ukugeleza koketshezi, amagesi, noma ezinye izinto ngokusebenzisa uhlelo lwamapayipi. Ama-valve adlala indima ebalulekile ezimbonini ezahlukahlukene, ukuqinisekisa ukulawulwa okunembile, ukuphepha, kanye nokusebenza kahle ekuthuthweni koketshezi kanye nokuphathwa kwenqubo.

Imisebenzi Eyinhloko:

Ama-valve aklanyelwe ukwenza imisebenzi eminingana ebalulekile, okuhlanganisa:

● Ukuzihlukanisa: Ukuvala noma ukuvula ukugeleza kwemidiya ukuze kuhlukaniswe izingxenye ezahlukene zesistimu.

● Umthethonqubo: Ukulungisa izinga lokugeleza, ingcindezi, noma isiqondiso semidiya ukuze kuhlangatshezwane nezidingo ezithile.

● Ukuvimbela ukugeleza emuva: Ukuvimbela ukuguqulwa kokugeleza kwemidiya ukuze kulondolozwe ubuqotho bohlelo.

● Ukuphepha: Ukukhulula ingcindezi eyengeziwe ukuvimbela ukugcwala ngokweqile kwesistimu noma ukuqhekeka.

● Ukuxuba: Ukuhlanganisa izinto ezahlukene ukuze kufezwe ukwakheka okufiselekayo.

● Ukuphambukisa: Ukuqondisa kabusha imidiya ezindleleni ezahlukene ngaphakathi kohlelo.

Izinhlobo zama-Valve:

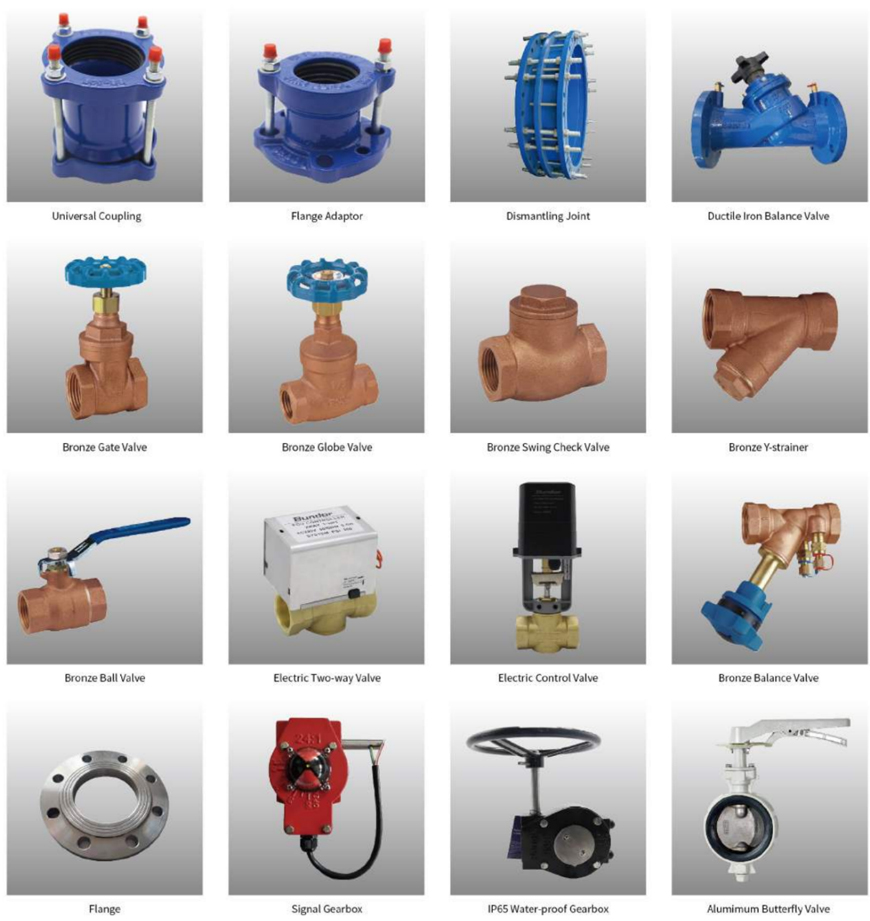

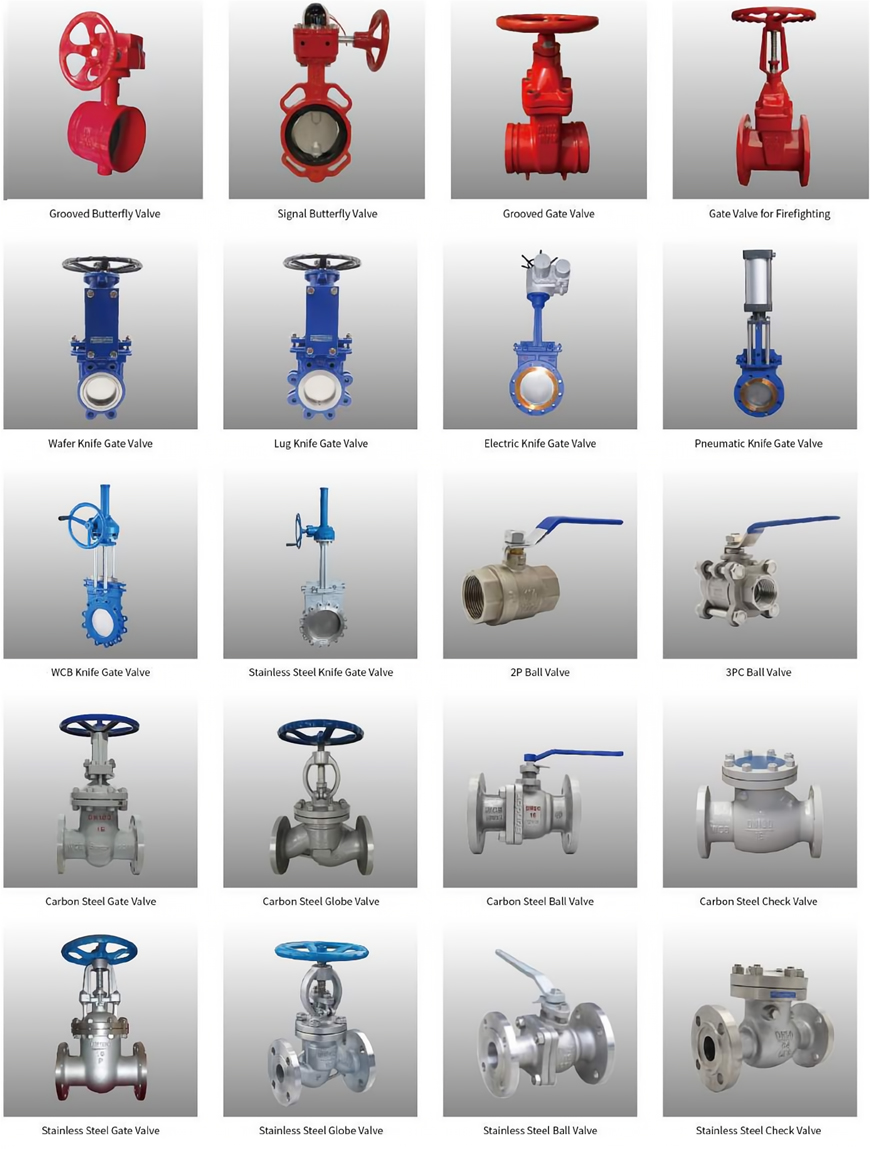

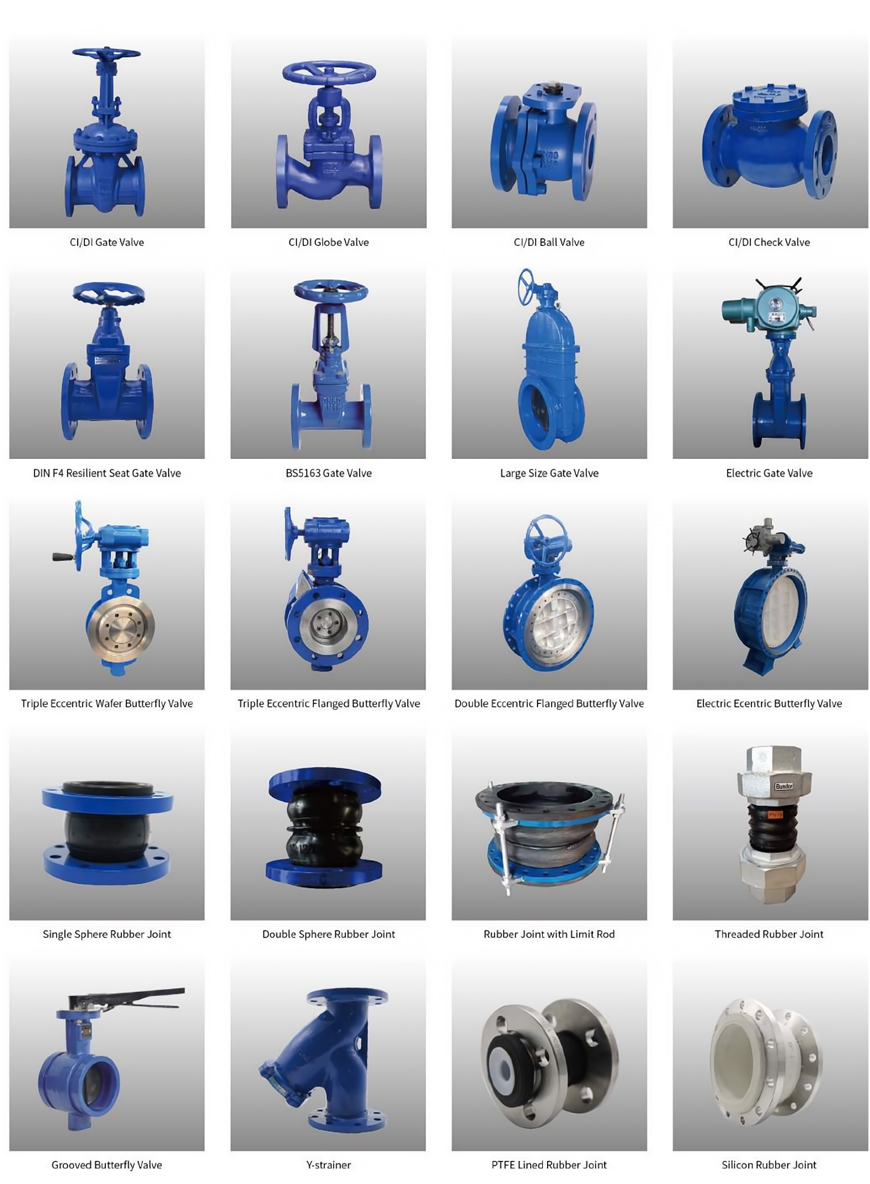

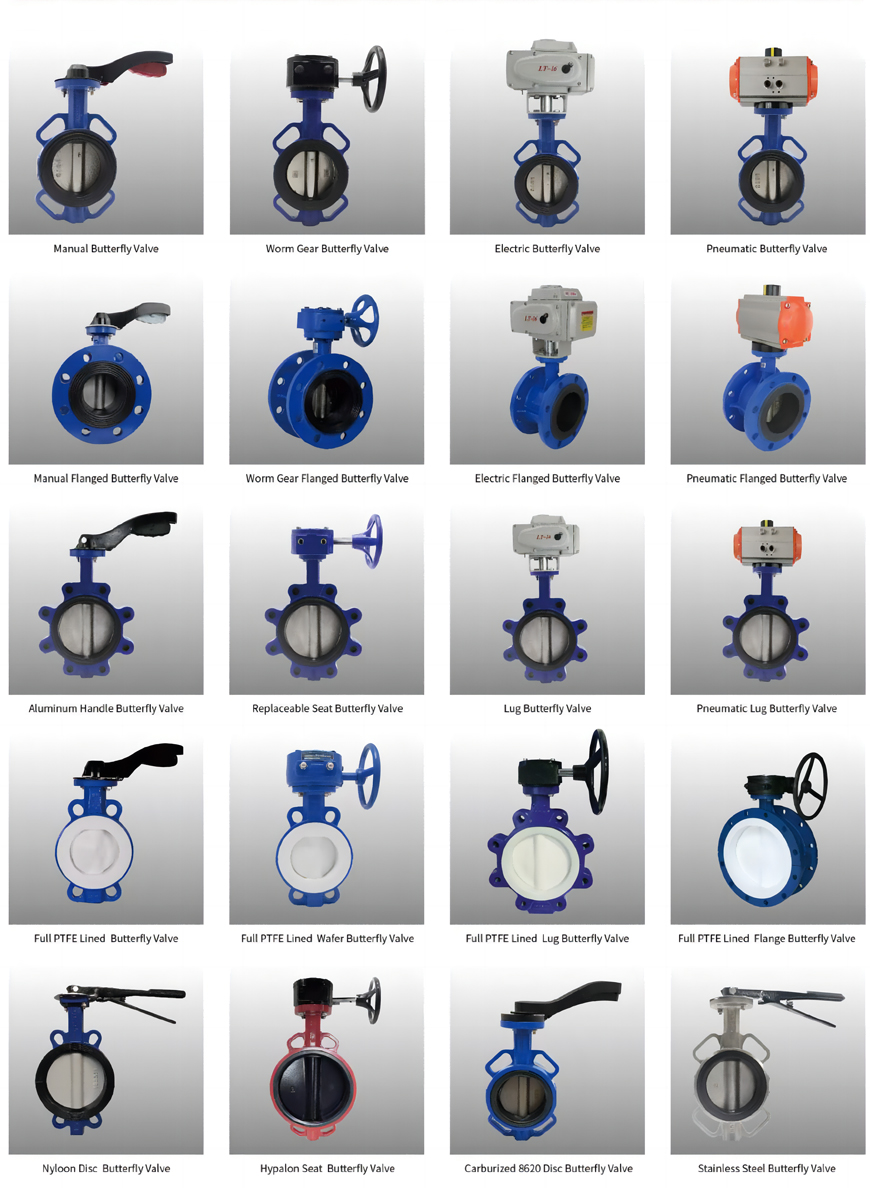

Kunezinhlobo eziningi zamavalvu, ngalinye lenzelwe ukubhekelela izinhlelo zokusebenza ezithile kanye nezimboni. Ezinye izinhlobo zamavalvu ezivamile zifaka amavalvu esango, amavalvu embulunga, amavalvu ebhola, amavalvu okuhlola, amavalvu ebhabhathane, kanye namavalvu okulawula.

Izingxenye:

Ivalvu evamile inezingxenye eziningana, okuhlanganisa nomzimba, ogcina indlela yokusebenza; i-trim, elawula ukugeleza; i-actuator, esebenza ngevalvu; kanye nezinto zokuvala, eziqinisekisa ukuvalwa okuqinile.

Imininingwane

| I-API 600: Insimbi Ehlanganisiwe, Insimbi Ehlanganisiwe, Insimbi Engagqwali |

| I-API 602: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Yengxubevange |

| I-API 609: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Yengxubevange |

| I-API 594: Insimbi Yekhabhoni, Insimbi Engagqwali |

| EN 593: Insimbi Ebunjiwe, Insimbi Ebunjiwe, Insimbi Yekhabhoni, Insimbi Engagqwali |

| I-API 598: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Yengxubevange |

| I-API 603: Insimbi Engagqwali, Insimbi Ehlanganisiwe |

| I-DIN 3352: Insimbi Ebunjiwe, Insimbi Ebunjiwe |

| I-JIS B2002: Insimbi Ehlanganisiwe, Insimbi Ehlanganisiwe, Insimbi Engagqwali |

| BS 5153: Insimbi Ehlanganisiwe, Insimbi Ehlanganisiwe |

Okujwayelekile kanye neBanga

| I-API 6D: Imininingwane Yama-Pipeline Valve - Ukuvalwa Kokuphela, Izixhumi, kanye Nama-Swivel | Izinto zokwakha: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

| I-API 609: Amavalvu Ebhabhathane: Uhlobo Oluphindwe Kabili Olune-Flanged, Lug- kanye ne-Wafer | Izinto zokwakha: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

| I-API 594: Ama-Check Valve: Iziphetho Ezine-Flanged, Lug, Wafer, kanye Ne-Butt-Welding | Izinto zokwakha: Insimbi Yekhabhoni, Insimbi Engagqwali

|

| EN 593: Amavalvu Ezimboni - Amavalvu Ebhamuza Elinsimbi | Izinto zokwakha: Insimbi Ebunjiwe, Insimbi Ebunjiwe, Insimbi Yekhabhoni, Insimbi Engagqwali |

| I-API 598: Ukuhlolwa Nokuhlolwa Kwevalvu | Izinto zokwakha: Insimbi Yekhabhoni, Insimbi Engagqwali, Insimbi Ehlanganisiwe |

| I-API 603: Amavalvu Esango Lebhonethi Elimelana Nokugqwala, Anebholithi - Iziphetho Zokushisela Ezinezinqe Nezinqe | Izinto zokwakha: Insimbi Engagqwali, Insimbi Ehlanganisiwe |

| I-DIN 3352: Amavalvu Esango Lensimbi Eqinile Ehlala Emihle | Izinto zokwakha: Insimbi Ehlanganisiwe, Insimbi Ehlanganisiwe |

| I-JIS B2002: Amavalvu Ovemvane | Izinto zokwakha: Insimbi Ehlanganisiwe, Insimbi Ehlanganisiwe, Insimbi Engagqwali |

| I-BS 5153: Imininingwane yama-Cast Iron kanye nama-Carbon Steel Swing Check Valve | Izinto zokwakha: Insimbi Ehlanganisiwe, Insimbi Ehlanganisiwe |

Ikhwalithi yokulawula

Ukuhlolwa Kwezinto Ezingavuthiwe, Ukuhlaziywa Kwamakhemikhali, Ukuhlolwa Kwemishini, Ukuhlolwa Okubonakalayo, Ukuhlolwa Kobukhulu, Ukuhlolwa Kokugoba, Ukuhlolwa Kokuthamba, Ukuhlolwa Komthelela, Ukuhlolwa Kwe-DWT, Ukuhlolwa Okungonakalisi, Ukuhlolwa Kokuqina, Ukuhlolwa Kokucindezela, Ukuhlolwa Kokuvuza Kwesihlalo, Ukuhlolwa Kokusebenza Kokugeleza, Ukuhlolwa Kwe-Torque kanye Nokuthungwa, Ukuhlolwa Kokupenda Nokumboza, Ukubuyekezwa Kwamadokhumenti…..

Ukusetshenziswa Nokusetshenziswa

Ama-valve ayizingxenye ezibalulekile ezidlala indima ebalulekile ezimbonini ezahlukahlukene ngokulawula, ukulawula, nokuqondisa ukugeleza koketshezi, amagesi, kanye nomusi. Ukusebenza kwawo okuguquguqukayo okuqinisekisa ukusebenza kahle, ukuphepha, kanye nokusebenza kahle kuzo zonke izinhlelo zokusebenza ezahlukahlukene.

Ama-valve esiwakhiqiza ngensimbi iWomic asetshenziswa kabanzi ezinqubweni zezimboni, uwoyela negesi, ukwelashwa kwamanzi, ukukhiqizwa kwamandla, izinhlelo ze-HVAC, imboni yamakhemikhali, imithi, izimoto nezokuthutha, ezolimo nokunisela, ukudla neziphuzo, izimayini namaminerali, izinhlelo zezokwelapha, ukuvikelwa komlilo njll.

Ukuzivumelanisa nezimo, ukunemba, kanye nokuthembeka kwama-valve kuwenza abe yinto ebalulekile emikhakheni eminingi, ukuvikela imisebenzi, ukwenza ngcono izinqubo, kanye nokuthuthukisa ukuphepha nokusebenza kahle okuphelele.

Ukupakisha Nokuthumela

Ukupakisha:

Ivalvu ngayinye ihlolwa ngokucophelela futhi ihlolwe ngaphambi kokupakisha ukuqinisekisa ukuthi ihlangabezana nezindinganiso zethu zekhwalithi eziqinile. Amavalvu asongwa futhi avikelwe ngamanye kusetshenziswa izinto ezivunyelwe yimboni ukuvimbela noma yimuphi umonakalo ngesikhathi sokuthuthwa. Sinikeza izinketho zokupakisha ezenziwe ngokwezifiso ngokusekelwe ohlotsheni lwevalvu, usayizi, kanye nezidingo zamakhasimende ezithile.

Zonke izesekeli ezidingekayo, imibhalo, kanye nemiyalelo yokufaka kufakiwe ephaketheni.

Ukuthunyelwa:

Sisebenzisana nabalingani bethu bokuthumela impahla abathembekile ukuqinisekisa ukulethwa okuthembekile nokufika ngesikhathi endaweni yakho ecacisiwe. Ithimba lethu lezokuthutha lenza ngcono imizila yokuthumela impahla ukuze linciphise izikhathi zokuhamba futhi linciphise ingozi yokubambezeleka. Ngokuthunyelwa kwamanye amazwe, siphatha yonke imibhalo yamasiko edingekayo kanye nokuhambisana nemithetho ukuze kube lula ukusulwa kwamasiko okushelelayo. Sinikeza izinketho zokuthumela eziguquguqukayo, okuhlanganisa nokuthunyelwa okusheshayo kwempahla ngezidingo eziphuthumayo.