Incazelo Yomkhiqizo

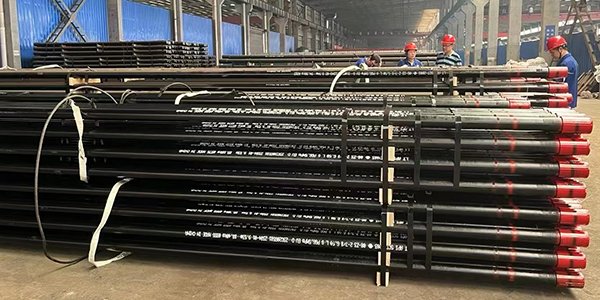

Ipayipi lokubhoboza elisetshenziselwa ukuxhumanisa imishini engaphezulu yerigi yokubhoboza nemishini yokugaya noma yokubhoboza, liyipayipi lensimbi elineziphetho zentambo, futhi lenza uxhumano lwemishini yembobo engezansi yokubhoboza. Ipayipi lokubhoboza livame ukuhlukaniswa libe yi-kelly, ipayipi lokubhoboza kanye nepayipi lokubhoboza elisindayo. Amapayipi Okubhoboza Ensimbi aza ngobukhulu obuhlukahlukene, amandla, kanye nobukhulu bodonga, kodwa ngokuvamile angamafidi angu-27 kuya kwangu-32 ubude (Ububanzi 2). Kukhona ubude obude, obufika kumamitha angu-45, (Ububanzi 3).

Ikhola yokubhoboza iyisigaba esiyinhloko sethuluzi lokubhoboza elingezansi, lisebenza phansi kwentambo yokubhoboza. Ubukhulu bekhola yokubhoboza bukhulu, kanye nobukhulu bamandla adonsela phansi kanye nokuqina. Ukuze kuthuthukiswe umsebenzi wokukhubeka, ukucubungula imigoqo ye-elevator kanye nemigoqo eshelelayo ebusweni bangaphandle bentambo yangaphakathi yekhola yokubhoboza kungaba ukukhetha okuhle. Amakhola okubhoboza ajikelezayo, amakhola okubhoboza ahlanganisiwe, kanye namakhola okubhoboza angewona amagnetic yiwona amakhola okubhoboza ayinhloko emakethe.

Imininingwane

| I-API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| I-API 5CT: J55, K55, N80, L80, P110 |

| I-API 5D: E75, X95, G105, S135 |

| I-EN10210 :S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| I-ASTM A106: GR.A, GR.B, GR.C |

| I-ASTM A53/A53M: GR.A, GR.B |

| I-ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| I-ASTM A333: Ibanga 1, Ibanga 3, Ibanga 4, Ibanga 6, Ibanga 7, Ibanga 8, Ibanga 9. Ibanga 10, Ibanga 11 |

| I-DIN 2391: St30Al, St30Si, St35, St45, St52 |

| I-DIN EN 10216-1 : P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| I-JIS G3454: STPG 370, STPG 410 |

| I-JIS G3456: STPT 370, STPT 410, STPT 480 |

| I-GB/T 8163 :10#,20#,Q345 |

| I-GB/T 8162 :10#,20#,35#,45#,Q345 |

Okujwayelekile kanye neBanga

Amapayipi Okubhoboza Amabanga Ajwayelekile:

I-API 5DP, i-API Spec 7-1 E75, X95, G105 njll...

Izinhlobo Zokuxhumana: FH, IF, NC, REG

Izinhlobo Zemicu: NC26,NC31,NC38,NC40,NC46,NC50,5.1/2FH

Izinto: Insimbi yekhabhoni/Insimbi Engagqwali/Insimbi Ehlanganisiwe

Ipayipi lokubhoboza kufanele lilethwe ngokwezixhumi ezingenhla nezindinganiso ze-API5CT / API Standards.

Ikhwalithi yokulawula

Ukuhlolwa Kwezinto Ezingavuthiwe, Ukuhlaziywa Kwamakhemikhali, Ukuhlolwa Kwemishini, Ukuhlolwa Okubonakalayo, Ukuhlolwa Kokucindezeleka, Ukuhlolwa Kobukhulu, Ukuhlolwa Kokugoba, Ukuhlolwa Kokuthamba, Ukuhlolwa Komthelela, Ukuhlolwa Kwe-DWT, Ukuhlolwa Kwe-NDT, Ukuhlolwa Kwamanzi, Ukuhlolwa Kokuqina…..

Ukumaka, Ukupenda ngaphambi kokulethwa.

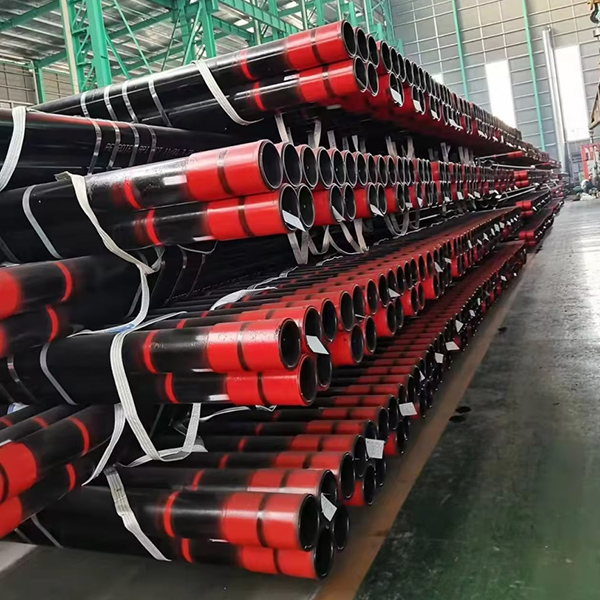

Ukupakisha Nokuthumela

Indlela yokufaka amapayipi ensimbi ihilela ukuhlanza, ukuqoqa, ukugoqa, ukubopha, ukubopha, ukulebula, ukufaka amaphalethi (uma kudingeka), ukufaka amabhokisi, ukuvala, ukuvala, ukuhambisa, kanye nokukhipha. Izinhlobo ezahlukene zamapayipi ensimbi nezinsimbi ezinezindlela ezahlukene zokupakisha. Le nqubo ephelele iqinisekisa ukuthi amapayipi ensimbi athunyelwa futhi afike lapho eya khona esesimweni esihle kakhulu, elungele ukusetshenziswa kwawo okuhlosiwe.

Ukusetshenziswa Nokusetshenziswa

Amapayipi ensimbi asebenza njengomgogodla wobunjiniyela bezimboni kanye nobezokwakha banamuhla, esekela izinhlelo zokusebenza eziningi ezifaka isandla ekuthuthukisweni kwemiphakathi kanye nomnotho emhlabeni jikelele.

Amapayipi ensimbi kanye nezinto zokufakelwa esizikhiqizele iWomic Steel ezisetshenziswa kabanzi kumapayipi kaphethiloli, igesi, uphethiloli kanye namanzi, amaphrojekthi okwakha amachweba olwandle kanye nokwakha, ukumba, insimbi yesakhiwo, amaphrojekthi okwakha amapulangwe kanye namabhuloho, kanye namapayipi ensimbi anembile okukhiqiza amarola okuhambisa, njll.