Incazelo Yomkhiqizo

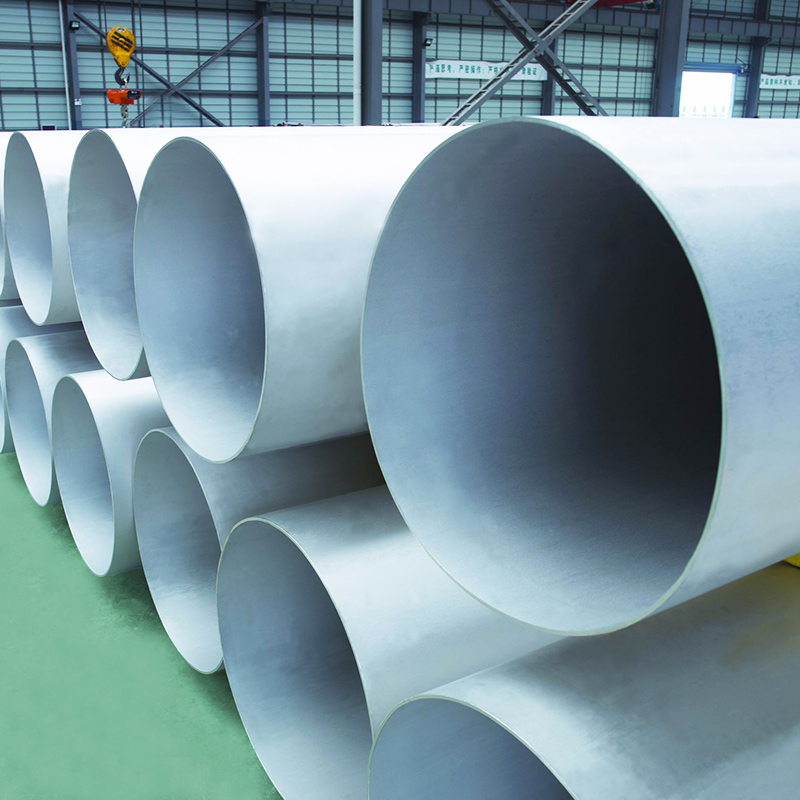

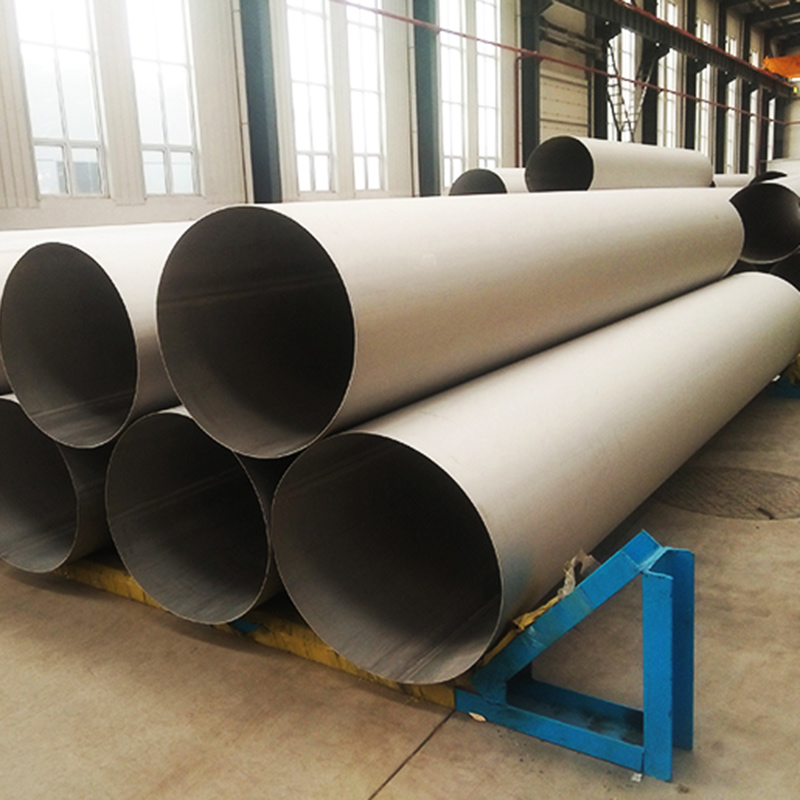

Amapayipi ahlanganisiwe ensimbi engagqwali ayizingxenye ezibalulekile ezimbonini eziningi ngenxa yokuqina kwawo, ukumelana nokugqwala, kanye nokuguquguquka. Lawa mapayipi enziwa ngenqubo yokushisela, ehlanganisa amashidi ensimbi engagqwali noma imichilo ukuze akhe amapayipi asilinda. Nasi isifinyezo esibanzi samapayipi ahlanganisiwe ensimbi engagqwali:

Izinto zokwakha kanye namaBanga:

● Uchungechunge lwe-304 no-316: Amamaki ensimbi engagqwali ajwayelekile asetshenziswa kabanzi.

● 310/S kanye no-310H: Insimbi engagqwali engamelana nokushisa okuphezulu yezicelo zesithando somlilo kanye ne-heat-exchange.

● 321 kanye no-321H: Amazinga amelana nokushisa afanele izindawo zokushisa eziphakeme.

● 904L: Ingxubevange evikela kakhulu ukugqwala ezindaweni ezinolaka.

● S31803: Insimbi engagqwali ephindwe kabili, enikeza kokubili amandla kanye nokumelana nokugqwala.

Inqubo Yokukhiqiza:

● Ukushisela Okuhlanganisiwe Kukagesi (EFW): Kule nqubo, umthungo oqondile ushiselwa ngokusebenzisa amandla kagesi ku-arc yokushisela.

● Ukushisela i-Arc Ecmerged (SAW): Lapha, ukushisela kwenziwa ngokuncibilikisa imiphetho nge-arc eqhubekayo ecwiliswe ekugelezeni.

● Ukushisela Okusheshayo Okuphezulu (i-HFI): Le ndlela isebenzisa imisinga eshesha kakhulu ukudala umthungo wokushisela enkambisweni eqhubekayo.

Izinzuzo:

● Ukumelana Nokugqwala: Imelana nezinhlobo eziningi zemidiya egqwalayo kanye nezindawo ezizungezile.

● Amandla: Amandla aphezulu okusebenza aqinisekisa ubuqotho besakhiwo.

● Ukuguquguquka: Itholakala ngobukhulu obuhlukahlukene, amamaki, kanye nokuqedwa ukuze ivumelane nezinhlelo zokusebenza ezahlukene.

● Ukuhlanzeka: Kufanelekile ezimbonini ezinezidingo eziqinile zokuhlanzeka.

● Ubude Besikhathi: Ibonisa ukuqina okumangalisayo, okuholela ebude besikhathi senkonzo.

Ngamafuphi, amapayipi ahlanganisiwe ensimbi engagqwali ayizici ezibalulekile kuzo zonke izimboni, ahlinzeka ngokuqina, ukumelana nokugqwala, kanye nokuguquguquka kwezinhlelo ezahlukahlukene. Ukukhetha kahle ibanga, indlela yokukhiqiza, kanye nokunamathela ezindinganisweni zemboni kubalulekile ekuqinisekiseni ukusebenza kahle kanye nokuphepha kwezinhlelo zamapayipi ahlanganisiwe.

Imininingwane

| I-ASTM A312/A312M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H njll.... |

| EN 10216-5: 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 njll... |

| I-DIN 17456: 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 njll... |

| I-JIS G3459: SUS304TB, SUS304LTB, SUS316TB, SUS316LTB njll.. |

| GB/T 14976: 06Cr19Ni10, 022Cr19Ni10, 06Cr17Ni12Mo2 |

| Insimbi engagqwali yase-Austenitic:TP304, TP304L, TP304H, TP310S, TP316, TP316L, TP316H, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H, TP347HFG N08904(904L), S30432, S31254, N08367, S30815... Insimbi engagqwali ephindwe kabili:S31803, S32205, S32750, S32760, S32707, S32906... I-Nickel Alloy:N04400, N06600, N06625, N08800, N08810(800H), N08825... Ukusetshenziswa:Izimboni zokukhiqiza uphethiloli, amakhemikhali, igesi yemvelo, amandla kagesi kanye nemishini yemishini. |

| DN mm | NB Intshi | OD mm | I-SCH40S mm | I-SCH5S mm | I-SCH10S mm | I-SCH10 mm | I-SCH20 mm | I-SCH40 mm | I-SCH60 mm | I-XS/80S mm | I-SCH80 mm | I-SCH100 mm | I-SCH120 mm | I-SCH140 mm | I-SCH160 mm | I-SCHXXS mm |

| 6 | 1/8” | 10.29 | 1.24 | 1.73 | 2.41 | |||||||||||

| 8 | 1/4” | 13.72 | 1.65 | 2.24 | 3.02 | |||||||||||

| 10 | 3/8” | 17.15 | 1.65 | 2.31 | 3.20 | |||||||||||

| 15 | 1/2” | 21.34 | 2.77 | 1.65 | 2.11 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | 3/4” | 26.67 | 2.87 | 1.65 | 2.11 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 1” | 33.40 | 3.38 | 1.65 | 2.77 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | 1 1/4” | 42.16 | 3.56 | 1.65 | 2.77 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | ||||||

| 40 | 1 1/2” | 48.26 | 3.68 | 1.65 | 2.77 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | 2” | 60.33 | 3.91 | 1.65 | 2.77 | 3.91 | 5.54 | 5.54 | 9.74 | 11.07 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | ||||||

| 80 | 3” | 88.90 | 5.49 | 2.11 | 3.05 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | ||||||

| 90 | 3 1/2” | 101.60 | 5.74 | 2.11 | 3.05 | 5.74 | 8.08 | 8.08 | ||||||||

| 100 | 4” | 114.30 | 6.02 | 2.11 | 3.05 | 6.02 | 8.56 | 8.56 | 11.12 | 13.49 | 17.12 | |||||

| 125 | 5” | 141.30 | 6.55 | 2.77 | 3.40 | 6.55 | 9.53 | 9.53 | 12.70 | 15.88 | 19.05 | |||||

| 150 | 6” | 168.27 | 7.11 | 2.77 | 3.40 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8” | 219.08 | 8.18 | 2.77 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 19.26 | 20.62 | 23.01 | 22.23 | |

| 250 | 10” | 273.05 | 9.27 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 | 12.70 | 15.09 | 19.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 300 | 12” | 323.85 | 9.53 | 3.96 | 4.57 | 6.35 | 10.31 | 14.27 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 350 | 14” | 355.60 | 9.53 | 3.96 | 4.78 | 6.35 | 7.92 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16” | 406.40 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 12.70 | 16.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |

| 450 | 18” | 457.20 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20” | 508.00 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |

| 550 | 22” | 558.80 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24” | 609.60 | 9.53 | 5.54 | 6.35 | 6.35 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26” | 660.40 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 700 | 28” | 711.20 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 750 | 30” | 762.00 | 9.53 | 6.35 | 7.92 | 7.92 | 12.70 | 12.70 | ||||||||

| 800 | 32” | 812.80 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 850 | 34” | 863.60 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 900 | 36” | 914.40 | 9.53 | 7.92 | 12.70 | 19.05 | 12.70 | |||||||||

| Ububanzi bepayipi obungu-DN 1000mm nangaphezulu. Ubukhulu bodonga lwepayipi okufanele lwenziwe ngokwezifiso. | ||||||||||||||||

Okujwayelekile kanye neBanga

| Okujwayelekile | Amabanga Ensimbi |

| I-ASTM A312/A312M: Amapayipi Ensimbi Engagqwali E-Austenitic Angenamthungo, Ashiselwe, Futhi Abandayo Kakhulu | 304, 304L, 310S, 310H, 316, 316L, 321, 321H njll... |

| I-ASTM A269: Amapayipi ensimbi engagqwali e-austenitic angenamthungo futhi ahlanganisiwe ukuze asebenze ngokujwayelekile | TP304, TP304L, TP316, TP316L, TP321.TP347 njll... |

| I-ASTM A249: Ibhoyila Yensimbi Ehlanganisiwe Ye-Austenitic, I-Superheater, I-Heat-Exchanger, kanye Nama-Condenser Tubes | 304, 304L, 316, 316L, 316H, 316N, 316LN, 317, 317L, 321, 321H, 347, 347H, 348 |

| I-ASTM A269: Amashubhu Ensimbi Engagqwali Angenamthungo Futhi Ahlanganisiwe Ensimbi Engagqwali Encane Enobubanzi Obuncane | 304, 304L, 316, 316L, 316H, 316N, 316LN, 317, 317L, 321, 321H, 347, 347H, 348 |

| I-ASTM A270: Ipayipi Lokuhlanza Elingenamthungo Nelihlanganisiwe Le-Austenitic kanye ne-Ferritic/Austenitic | Amabanga e-Austenitic Stainless Steel: 304, 304L, 316, 316L, 316H, 316N, 316LN, 317, 317L, 321, 321H, 347, 347H, 348 Amazinga ensimbi engagqwali ye-Ferritic/Austenitic (Duplex): S31803, S32205 |

| I-ASTM A358/A358M: Izidingo Zepayipi Lensimbi Ehlanganisiwe Ye-Austenitic Yezindawo Ezinokushisa Okuphezulu, Ezinomfutho Ophakeme, Nezigqwala | 304, 304L, 316, 316L, 316H, 316N, 316LN, 317, 317L, 321, 321H, 347, 347H, 348 |

| I-ASTM A554: Amapayipi omshini wensimbi engagqwali ashiselwe, avame ukusetshenziswa ezinhlotsheni zokwakha noma zokuhlobisa | 304, 304L, 316, 316L |

| I-ASTM A789: Amapayipi ensimbi engagqwali e-ferritic/austenitic angenamthungo futhi ashiselwe ukuze asetshenziswe ngokujwayelekile | I-S31803 (Insimbi engagqwali ye-Duplex) I-S32205 (Insimbi engagqwali ye-Duplex) |

| I-ASTM A790: Ipayipi lensimbi engagqwali le-ferritic/austenitic elingenamthungo nelihlanganisiwe lenkonzo yokugqwala evamile, isevisi yokushisa okuphezulu, kanye namapayipi ensimbi engagqwali amabili. | I-S31803 (Insimbi engagqwali ye-Duplex) I-S32205 (Insimbi engagqwali ye-Duplex) |

| I-EN 10217-7: Amapayipi ensimbi engagqwali ahlanganisiwe Izidingo zokukhiqiza ezijwayelekile zaseYurophu. | 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4003, 1.4509, 1.4510, 1.4462, 1.4948, 1.4878 njll... |

| I-DIN 17457: Izinga lesiJalimane elisetshenziselwa ukukhiqiza amapayipi ahlanganisiwe ensimbi engagqwali | 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4003, 1.4509, 1.4510, 1.4462, 1.4948, 1.4878 njll... |

| I-JIS G3468: Izinga Lezimboni LaseJapan elichaza izidingo zokukhiqiza zamapayipi ensimbi engagqwali ahlanganisiwe. | I-SUS304, i-SUS304L, i-SUS316, i-SUS316L, i-SUS329J3L njll.. |

| I-GB/T 12771: Izinga Likazwelonke LaseShayina elisetshenziselwa izidingo zokukhiqiza amapayipi ahlanganisiwe ensimbi engagqwali. | 06Cr19Ni10, 022Cr19Ni1, 06Cr17Ni12Mo2, 022Cr22Ni5Mo3N |

| Insimbi engagqwali ye-Austenitic:TP304, TP304L, TP304H, TP310S, TP316, TP316L, TP316H, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H, TP347HFG N08904(904L), S30432, S31254, N08367, S30815... Insimbi engagqwali ephindwe kabili:S31803, S32205, S32750, S32760, S32707, S32906... I-Nickel Alloy:N04400, N06600, N06625, N08800, N08810(800H), N08825... Ukusetshenziswa: I-Petroleum, Amakhemikhali, Igesi Yemvelo, Amandla Kagesi kanye nezimboni zokukhiqiza imishini yemishini. | |

Ikhwalithi yokulawula

Ukuhlolwa Kwezinto Ezingavuthiwe, Ukuhlaziywa Kwamakhemikhali, Ukuhlolwa Kwemishini, Ukuhlolwa Okubonakalayo, Ukuhlolwa Kobukhulu, Ukuhlolwa Kokugoba, Ukuhlolwa Komthelela, Ukuhlolwa Kokugqwala Okuphakathi Kwezinhlayiya, Ukuhlolwa Okungonakalisiyo (UT, MT, PT) Inqubo Yokushisela, Ukuhlaziywa Kwesakhiwo Esincane, Ukuhlolwa Kokuvutha Nokuthamba, Ukuhlolwa Kokuqina, Ukuhlolwa Kokucindezela, Ukuhlolwa Kokuqukethwe Kwe-Ferrite, Ukuhlolwa Kwe-Metallography, Ukuhlolwa Kokugqwala, Ukuhlolwa Kwamanje Kwe-Eddy, Ukuhlolwa Kokufafaza Usawoti, Ukuhlolwa Kokumelana Nokugqwala, Ukuhlolwa Kokudlidliza, Ukuhlolwa Kokugqwala Kwe-Pitting, Ukuhlolwa Kokupenda Nokumboza, Ukubuyekezwa Kwamadokhumenti…..

Ukusetshenziswa Nokusetshenziswa

Amapayipi ahlanganisiwe ensimbi engagqwali asetshenziswa kakhulu emikhakheni eyahlukahlukene ngenxa yezakhiwo zawo ezihlukile kanye nokuguquguquka kwazo. Lawa mapayipi asetshenziswa ezinhlotsheni eziningi zezicelo, ngenxa yokuqina kwawo, ukumelana nokugqwala, kanye nokufaneleka kwawo ezindaweni ezahlukahlukene. Ezinye zezindawo ezibalulekile zokusetshenziswa kanye nokusetshenziswa kwamapayipi ahlanganisiwe ensimbi engagqwali zifaka:

● Ukusetshenziswa Kwezimboni: Kuvamile ezimbonini zikawoyela, igesi, i-petrochemical, kanye namandla ngenxa yokumelana nokugqwala.

● Ukwakhiwa: Kusetshenziswa ekufakweni kwamapayipi, ekuhlinzekweni kwamanzi, nasezindlini ngenxa yokuqina kwazo nokuphila isikhathi eside.

● Imboni Yokudla: Kubalulekile ekudluliseni ukudla neziphuzo, ukuhlangabezana nezindinganiso zokuhlanzeka.

● Izimoto: Zisetshenziswa ezinhlelweni zokukhipha ugesi kanye nezingxenye zesakhiwo, zibekezelela izimo ezinzima.

● Ezokwelapha: Kusetshenziswa kumadivayisi ezokwelapha kanye namapayipi okuhlanza, kubekwe phambili ukuhlanzeka.

● Ezolimo: Ngezinhlelo zokunisela ezingagqwali, ukuqinisekisa ukusatshalaliswa kwamanzi okuphumelelayo.

● Ukwelashwa Kwamanzi: Kufanelekela ukuthutha amanzi alungisiwe nakhishwe usawoti.

● Imikhumbi Yasolwandle: Imelana nokugqwala kwamanzi anosawoti, isetshenziswa kabanzi emikhunjini nasezindaweni ezisogwini lolwandle.

● Amandla: Ukuthutha uketshezi emkhakheni wamandla, okuhlanganisa igesi yemvelo kanye nowoyela.

● I-Pulp nePhepha: Kubalulekile ekuthuthweni kwamakhemikhali noketshezi enqubweni yokukhiqiza.

Ngamafuphi, amapayipi ahlanganisiwe ensimbi engagqwali asebenza njengezingxenye ezibalulekile ezimbonini eziningi kanye nezicelo. Ukumelana kwawo nokugqwala, amandla okusebenza, kanye nekhono lokuhlangabezana nezidingo eziqinile kuwenza abaluleke kakhulu engqalasizinda yesimanje, izinqubo zezimboni, kanye nemikhakha ehlukahlukene ekhethekile.

Ukupakisha Nokuthumela

Amapayipi ensimbi engagqwali ayapakishwa futhi athunyelwe ngokucophelela okukhulu ukuqinisekisa ukuvikeleka kwawo ngesikhathi sokuthutha. Nansi incazelo yenqubo yokupakisha nokuthumela:

Ukupakisha:

● Ukuvikela: Ngaphambi kokupakisha, amapayipi ensimbi engagqwali avame ukumbozwa ngesendlalelo samafutha noma ifilimu yokuvikela ukuvimbela ukugqwala nomonakalo womphezulu.

● Ukubopha: Amapayipi anobukhulu obufanayo kanye nemininingwane efanayo ahlanganiswa ngokucophelela. Aqiniswa kusetshenziswa izintambo, izintambo, noma amabhande epulasitiki ukuvimbela ukunyakaza ngaphakathi kwenqwaba.

● Izivalo Zokugcina: Izivalo zokugcina zepulasitiki noma zensimbi zifakwa kuzo zombili izinhlangothi zamapayipi ukuze kunikezwe isivikelo esengeziwe eziphethweni zamapayipi kanye nezintambo.

● Ukugoqa Nokusonga: Izinto zokufaka ama-padding ezifana ne-foam, i-bubble wrap, noma ikhadibhodi eligoqiwe zisetshenziselwa ukuhlinzeka ngokugoqa nokuvimbela umonakalo ngesikhathi sokuthuthwa.

● Amabhokisi noma Amabhokisi Okhuni: Kwezinye izimo, amapayipi angase apakishwe emabhokisini noma emabhokisini okhuni ukuze ahlinzeke ngesivikelo esengeziwe emandleni angaphandle nasekuphathweni.

Ukuthunyelwa:

● Indlela Yokuhamba: Amapayipi ensimbi engagqwali avame ukuthunyelwa kusetshenziswa izindlela ezahlukene zokuhamba njengemaloli, imikhumbi, noma imithwalo yendiza, kuye ngokuthi uyaphi kanye nokuphuthuma.

● Ukufakwa kweziqukathi: Amapayipi angafakwa ezitsheni zokuthumela impahla ukuqinisekisa ukuthi izinto zokuhamba ziphephile futhi zihlelekile. Lokhu kunikeza nokuvikelwa ezimweni zezulu kanye nokungcola kwangaphandle.

● Ukulebula kanye Nemibhalo: Iphakheji ngayinye ilebula ngolwazi olubalulekile, okuhlanganisa imininingwane, ubuningi, imiyalelo yokuphatha, kanye nemininingwane yendawo oya kuyo. Amadokhumenti okuthumela alungiselelwa ukusulwa kwempahla kanye nokulandelwa kwempahla.

● Ukuthobela Imithetho Yentela: Ngokuthunyelwa kwamanye amazwe, yonke imibhalo yentela edingekayo ilungiselelwe ukuqinisekisa ukuthi izimpahla zifika kalula endaweni oya kuyo.

● Ukubopha Okuqinile: Ngaphakathi kwemoto yokuthutha noma isitsha, amapayipi aboshwe kahle ukuze kuvinjelwe ukunyakaza nokunciphisa ingozi yomonakalo ngesikhathi sokuthutha.

● Ukulandelela Nokuqapha: Izinhlelo zokulandelela ezithuthukisiwe zingasetshenziswa ukuqapha indawo kanye nesimo sokuthunyelwa ngesikhathi sangempela.

● Umshwalense: Kuye ngenani lempahla, umshwalense wokuthumela ungatholakala ukuze umboze ukulahlekelwa noma umonakalo ongaba khona ngesikhathi sokuthutha.

Ngamafuphi, amapayipi ensimbi engagqwali esiwakhiqizile azopakishwa ngezinyathelo zokuzivikela futhi athunyelwe kusetshenziswa izindlela zokuthutha ezinokwethenjelwa ukuqinisekisa ukuthi afika lapho aya khona esesimweni esihle kakhulu. Izinqubo ezifanele zokupakisha nokuthumela zinegalelo ekuqineni nasekhwalithini yamapayipi alethiwe.